6-6T-309

Table 6-1 Compressor Kit

Item

Component Qty

1 Compressor 1

2 Service Valve Seal 3

3 Mylar Washers 4

4 Wire Tie 2

5 Oil Sight Glass Plug 1

6 Resilient Mount 4

7 Upper Shock Mount Ring 1

8 Upper Shock Mount Bushing 1

9 Compressor Power Plug O--Ring 1

10 SST Washers 8

c. If the compressor is not operational, turn the unit

start--stop switch (ST) and unit circuit breaker

(CB--1) OFF. Disconnect power to theunit and front--

seatthe discharge, suction, economizer,and oil return

service valves.

Remove all remaining refrigerant from the compres-

sor using a refrigerant recovery system. Connect

hoses to suction, economizer and discharge service

valves ports. Evacuate compressor to 500 microns

(75.9 cm Hg vacuum = 29.9 inches Hg vacuum).

d. Make sure power to the unit is OFF and unit power

plug disconnected. Disconnect the power plug from

the compressor.

e. Loosen and break the seal at fittings from the suction,

discharge, economizer, and the oil return service

valves. Remove fittings and discard service valve

seals, retain oil return valve O--ring.

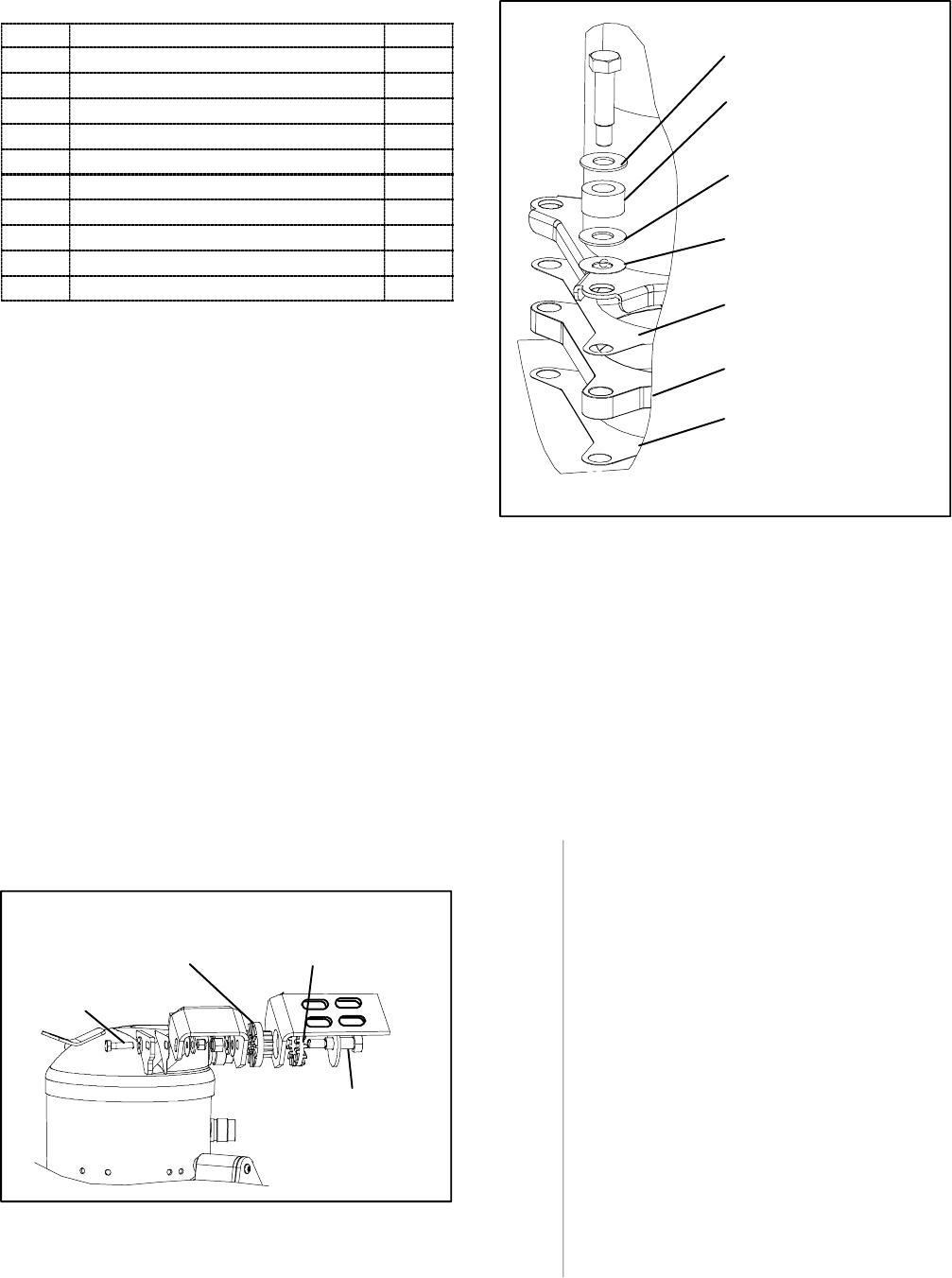

f. Remove the entire compressor upper mounting

bracket assembly,(see F igure 6-7) by removing the

fourcapscrewsattachingit t o the unit and the 32--mm

bolt from the compressor mounting bracket.

Upper Shock Mount

Bushing(KitItem8)

Upper Shock Mount

Ring (Kit Item 7)

Shoulder Bolt

32mm Bolt

Figure 6-7 Compressor Upper Mounting

Resilient Mount

(Kit Item 6)

Mylar Washer

(Kit Item 3)

Mylar Protector

(Retain)

Base Plate

(Retain)

Mylar Protector

(Retain)

SST Washer

(Kit Item 10)

SST Washer

(Kit Item 10)

Figure 6-8 Compressor Lower Mounting

g. Replace the upper mounting bracket shock mount

ring and bushing (kit items 7and 8). Reassemble the

bracket in the same manner as the original and torque

the shoulder bolt to 2.8 mkg (20 ft--lbs.).

h. Remove the male coupling from the top of t he sight

glass on the old compressor and hand assemble to the

oil return valve coupling for safe keeping. Plug the

top of the replacement compressor sight glass with

the plug (kit item 5) to prevent spilling oil.

i. Remove the lower mounting bolts and hardware (see

Figure 6-8). Using plugs from replacement compres-

sor, plug connections on old compressor. Removethe

old compressor. Refer to paragraph 2.2for compres-

sor weight. Return plugs to replacement compressor.

j. The replacement compressor is shipped with an oil

charge of 591ml (20 ounces). Before sliding t he new

compressori n the unit, removetheoil sight glassplug

and (using a small funnel) charge the compressor

with an additional 1893ml (64 ounces) Castrol--Ice-

maticSW20(POE oil).Reassembletheoilsight glass

plug toavoid spilling oilwhensliding thecompressor

in the unit.

k. Secure the base plate and mylar protectors to the com-

pressor with wire ties (kit item 4), and place the com-

pressor in the unit.

l. Cut and remove the wire ties that were used to hold

the base plate and protectors to the compressor. Us-

ing new resilient mounts, SST washers and mylar

washers (kit items 3, 6 & 10). Install the four mount-

ing screws loosely.

m.Install themalecoupling (removedin step h.) into the

sight glass port.