6-8T-309

6.10.2 Checking High Pressure Switch

WARNING

Do not u se a nitrogen cylinder without a

pressure regulator. Do not use oxygen in or

near a refrigeration system as an explosion

may occur.

NOTE

The high pressure switch is non-adjustable.

a. Remove switch as outlined in paragraph 6.10.1

b. Connect ohmmeter or continuity light across switch

terminals. Ohm meter will indicate no resistance or

continuity light will be illuminated if the switch

closed after relieving compressor pressure.

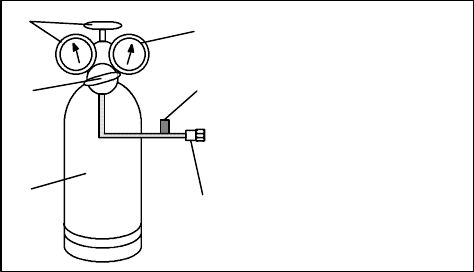

c. Connect hose to a cylinder of dry nitrogen. (See

Figure 6-9.)

1. Cylinder Valve

and Gauge

2. Pressure Regulator

3. Nitrogen Cylinder

4. Pressure Gauge

(0 to 36 kg/cm@ =

0 to 400 psig)

5. Bleed-Off Valve

6. 1/4 inch Connection

1

2

3

4

5

6

Figure 6-9 High Pressure Switch Testing

d. Set nitrogen pressure regulator at 26.4 kg/cm@ (375

psig) with bleed-off valve closed.

e. Close valve on cylinder and open bleed-off valve.

f. Open cylinder valve. Slowly close bleed-off valve to

increase pressure on switch. The switch should open

at a static pressure up to 25 kg/cm@ (350 psig). If a

light is used, light willgo out.If an ohmmeter is used,

the meter will indicate open circuit.

g. Slowly open bleed-off valve to decrease the pressure.

The switch should close at 18 kg/cm@ (250 psig).

6.11 CONDENSER COIL

The condenser consists of a s eries of parallel copper

tubes expanded into copper fins. The condenser coil

must becleaned withfresh water or steam so the airflow

is not restricted. To replace the coil, do the following:

WARNING

Do not open the condenser fan grille before

turning power OFF and disconnecting

power plug.

a. Using a refrigerant reclaim system, remove the

refrigerant charge.

b. Remove the condenser coil guard.

c. Unsolder discharge line and remove the line to t he

receiver or water-cooled condenser.

d. Remove coil mounting hardware and remove the

coil.

e. Install replacement coil and solder connections.

f. Leak-check the coil connections per paragraph para-

graph 6.5. Evacuate the unit per paragraph 6.6 then

charge the unit with refrigerant per paragraph 6.7.

6.12 CONDENSER FAN AND MOTOR ASSEMBLY

WARNING

Do not open condenser fan grille before

turning power OFF and disconnecting

power plug.

The condenser fan rotates counter-clockwise (viewed

from front of unit), pulls air through the the condenser

coil, and discharges horizontally throughthe front ofthe

unit. To replace motor assembly:

a. Open condenser fan screen guard.

b. Loosen two square head set screws on fan. (Thread

sealer has been applied to set screws at installation.)

Disconnect wiring from motor junction box.

CAUTION

Take necessary steps (place plywood over

coil or use sling on motor) to p revent motor

from falling into condenser coil.

c. Remove motor mounting hardware and replace the

motor. It is recommended that new locknuts be used

when replacing motor. Connect wiring per wiring

diagram.

d. Install fan loosely on motor shaft (hub side in). DO

NOT USE FORCE. If necessary,tap thehub only, not

the hub nuts or bolts. Install venturi. Apply “Loctite

H” to fan set screws. Adjust fan within venturi so that

the outer edge of the fan is within 2.0 ± .07 mm

(0.08” ¦ 0.03”) from the outside of the orifice open-

ing. Spin fan by hand to check clearance.

e. Close and secure condenser fan screen guard.

f. Apply power to unit and check fan rotation. If fan

motor rotates backward, reverse wire numbers 5 and

8.

6.13 FILTER-DRIER

On units equipped with a water-cooled condenser, if the

sight glass appears to be flashing or bubbles are

constantly moving through the sight glass when the

suction modulation valve is fully open, the unit may

have a l ow refrigerant charge or the filter-drier could be

partially plugged.

a. To Check Filter-Drier

1. Test for a restricted or plugged filter-drier by feeling

the liquid line inlet and outlet connections of the

drier cartridge. If the outlet side feels cooler than the

inlet side, then the filter-drier should be changed.