6-7

T -309

n. Place the new service seals (kit item 2) at the com-

pressor service ports, connect the four service valves

loosely.

o. Torque the fourresilient mount screws to 6.2 mkg(45

ft--lbs).

p. Torque the four service valves to:

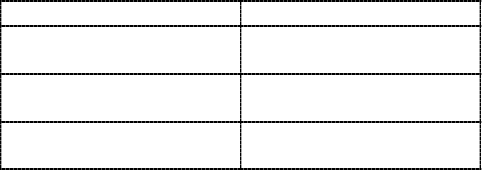

Service V alve Torque

Suction or Discharge 11 to 13.8 mkg

(80 to 100 ft--lbs.)

Economizer 6.9to8.3mkg

(50to60ft--lbs.)

Oil Return 1.4to1.66mkg

(10to12ft--lbs.)

q. Reassemble the top mounting bracket (see

Figure 6-7) by hand tightening the 32--mm (1¼

--inch) bolt and torquing the four mounting screws to

0.9 mkg (6.5 ft--lbs). Align the mounting so that the

ring and bushing assembly are free with no compres-

sion.

r. Torque the 32mm bolt to 1.5 mkg (11 ft--lbs. ). While

maintaining the free movement of the shock mount,

torque the four mounting screws to 0.9 mkg (6.5 ft--

lbs.).

s. R eplace the power plug O--Ring with new ring (kit

item 9). Insert the power plug into thecompressor fit-

ting. Be sure plug is fully seated into the fitting and

then thread the coupling nut a minimum of 5 turns.

t. Leak check and evacuate the compressor to 1000 mi-

crons. Refer to paragraphs

6.5 and 6.6

u. Run the unit for at least 15 minutes and check the oil

and refrigerant levels. Refer to paragraphs 6.7 and

6.9.

6.9 COMPRESSOR OIL LEVEL

CAUTION

Use only Carrier Transicold approved

Polyol Ester Oil (POE) -- Mobil ST32 com-

pressor oil with R-134a. Buy in quan tities of

one quartor smaller. When using this hygro-

scopic oil, immediately reseal. Do not leave

container of oil open or contamination will

occur.

a. Checking the Oil Level in the Compressor

1 Ideally, ambient temperature should be between

40_F and 100_ F.

2 Operate the unit in cooling mode for at least 20 min-

utes.

3 C heck the controller function code Cd1 for the suc-

tion modulation valve (SMV) position. It should be

at least 20% open.

4 Locate the oil sight glass on t he side of the compres-

sor (item

7, Figure 2-3).

5 Turn Start/Stop switch offand allowoil to draininto

compressor sump. Oil level must be visible in the

sight glass. Ifit is notvisible, oil must beaddedtothe

compressor.

b. Adding Oil with Compressor in System

1. The recommended method is to add oil using an oil

pump at the oil return service valve (see item

15,

Figure 2-3

)

2. In an emergency where an oil pump is not available,

oil m ay bedrawn i nto the compressorthrough the oil

return service valve.

Connect the suction connection of the gauge man-

ifold to the compressor oil return valve port, and

immerse the common connection of the gauge man-

ifold in an open container of refrigeration oil.

Extreme care must be taken to ensure the manifold

common connection remains immersed in oil at all

times. Otherwiseair and moisture will be drawn into

the compressor. Crack the oil return service valve

andgauge valveto venta small amountof refrigerant

through the common connection and theoil to purge

the lines of air. Cl ose the gauge manifold valve.

With the unit running, turn the suction service valve

toward frontseat and induce a vacuum in the com-

pressor crankcase. Do not allow the compressor to

pull below 127mm/hg (5 “/hg). SLOWLY crack the

suction gauge manifold valve and oil will flow

throughthe oil return servicevalveinto thecompres-

sor. Add oil as necessary.

3 R un unit for 20 minutes in cooling mode. Check oil

level at the compressor sight glass.

c. Removing Oil from the Compressor:

1 If the oil level is above the sight glass, oil must be

removed from the compressor.

2 Perform a compressor pump down, refer to section

6.4.

3 Remove theoil plug, and drain oil until a level can be

seen in the sight glass.

4 R un unit for 20 minutes in cooling mode. Check oil

level at the compressor sight glass.

6.10 HIGH PRESSURE SWITCH

6.10.1 Replacing High Pressure Switch

a. Turn unit start-stop switch OFF. Frontseat the suc-

tion, discharge, economizer and oil return service

valves to isolate compressor. Remove the refrigerant

from the compressor.

b. Disconnect wiring from defective switch. The high

pressure switch is located on the discharge service

valve and is removed by turning counterclockwise.

(See Figure 2-3.)

c. Install a new high pressure switch a fter verifying

switch settings. (Refer t o paragraph 6. 10.2.)

d. Evacuate and dehydrate the compressor per para-

graph 6. 6.