* [LIMIT] is shown on the LID as the temperature, pressure, voltage, etc., set point predefined or selected

by the operator as an override, alert, or alarm condition. [VALUE] is the actual pressure, temperature,

voltage, etc., at which the control tripped.

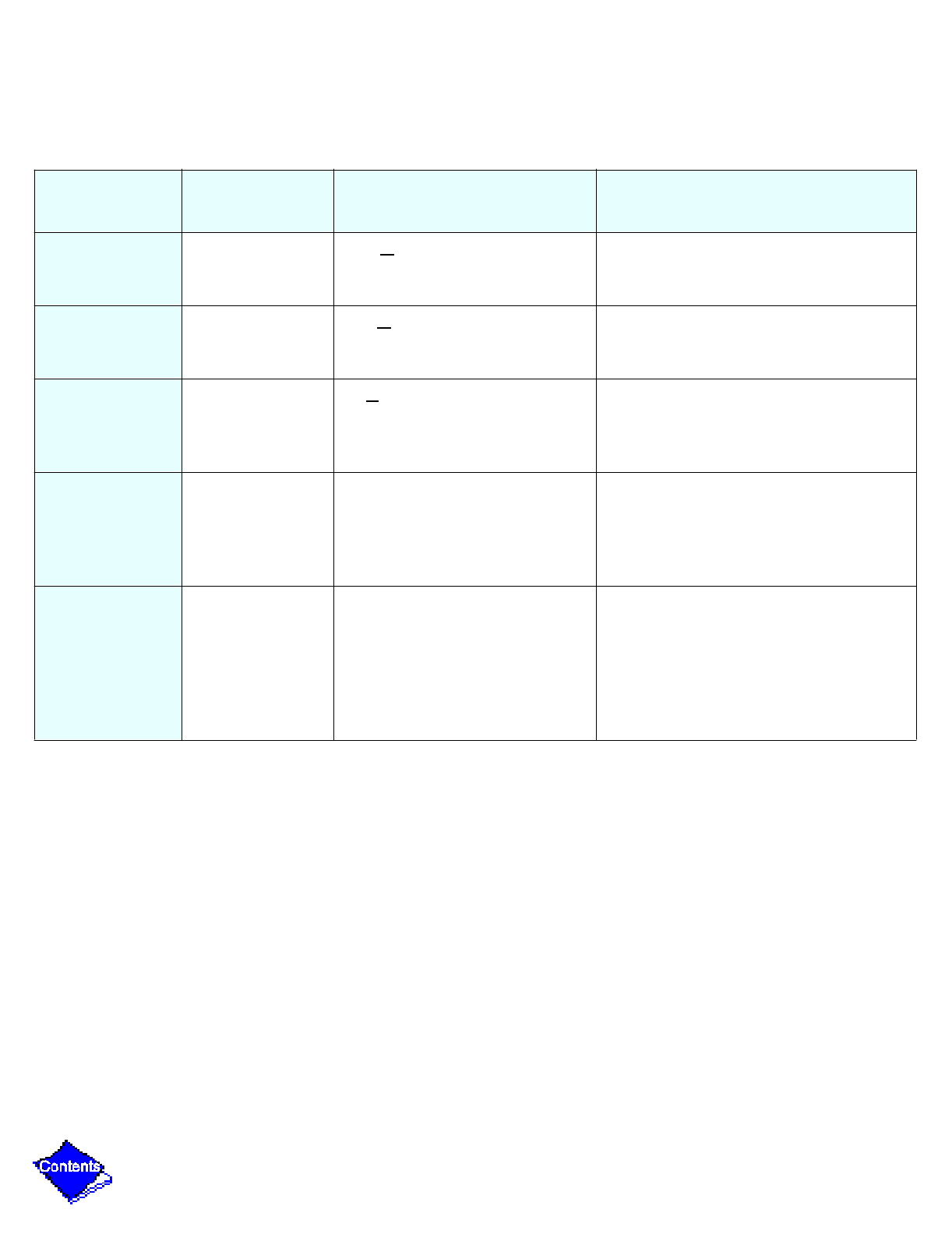

Failure To

Start

Starter Transi-

tion Fault

RUN AUX Starter Transition

Fault: Check 1CR/1M/Interlock

mechanism.

Check starter for proper operation. Run

contact failed to close.

Failure To

Start

1CR AUX Con-

tact Fault

1CR AUX Starter Contact

Fault: Check 1CR/1M aux. con-

tacts.

Check starter for proper operation. Start

contact failed to close.

Failure To

Start

Motor Amps Not

Sensed

CA P Motor Amps Not Sensed:

Check motor load signal.

Check for proper motor amps signal to

SMM. Check wiring from SMM to cur-

rent transformer. Check main motor cir-

cuit breaker for trip.

Failure To

Start

Check Refriger-

ant Type

Current Refrigerant Properties

Abnormal — Check Selection of

refrigerant type

Pressures at transducers indicate

another refrigerant type in Control Test.

Make sure to access the ATTACH TO

NETWORK DEVICE table after chang-

ing refrigerant type.

Failure To

Start

Low Oil Pressure Low Oil Pressure [LIMIT]:

Check oil pressure switch/

pump and 2C aux.

The oil pressure differential switch is

open when the compressor tried to

START. Check the switch for proper

operation. Also, check the oil pump

interlock (2C aux) in the power panel

and the high condenser pressure

switch.

Table 10F — Start-Up Failures: This is an alarm condition. A manual reset is required

to clear. (Continued)

Primary

Message

Secondary

Message

Alarm Message/Primary

Cause

Additional Cause/Remedy