* [LIMIT] is shown on the LID as the temperature, pressure, voltage, etc., set point predefined or selected

by the operator as an override, alert, or alarm condition. [VALUE] is the actual pressure, temperature,

voltage, etc., at which the control tripped.

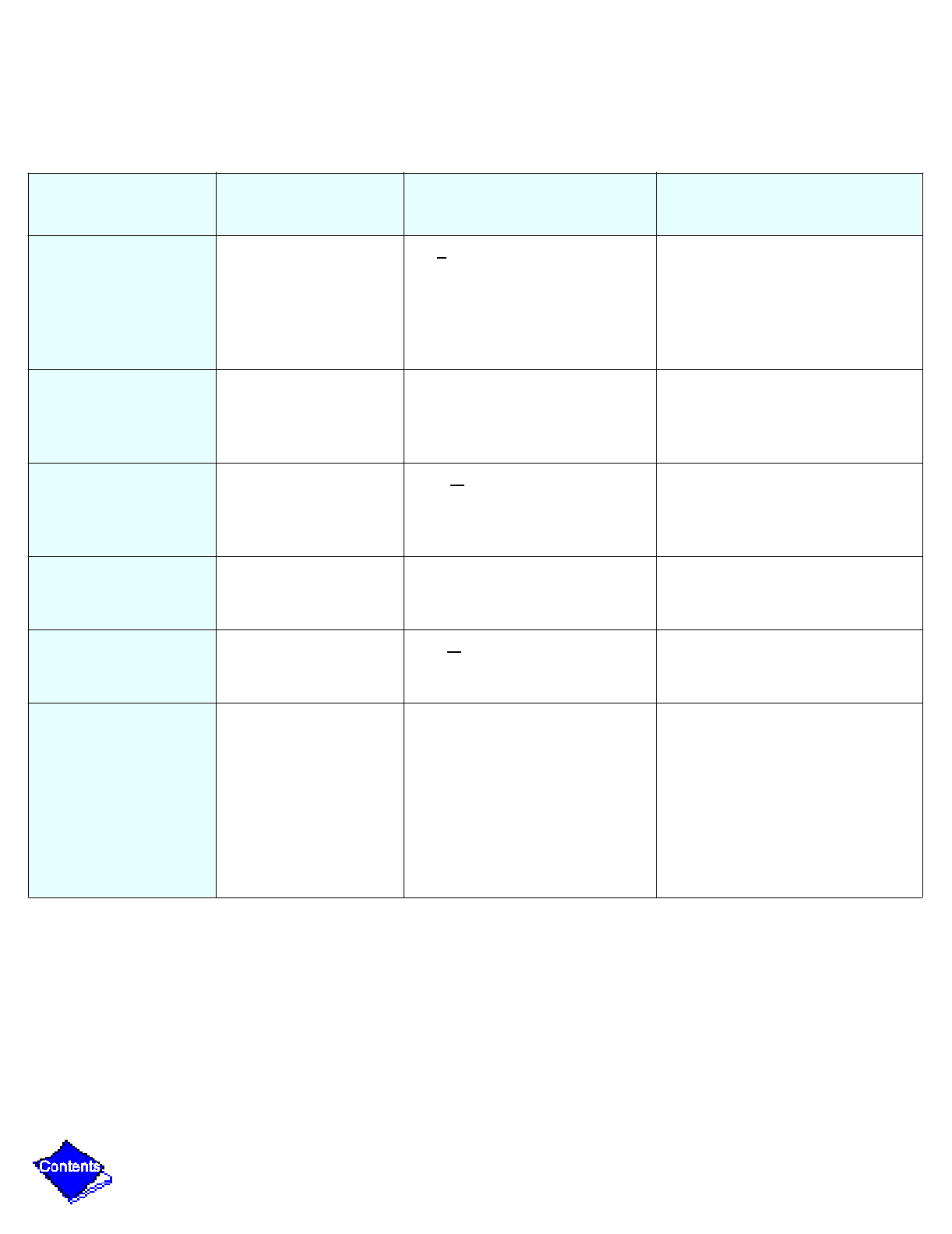

Table 10G — Compressor Jumpstart and Refrigerant Protection

Primary Message

Secondary

Message

Alarm Message/Primary

Cause

Additional Cause/Remedy

Unauthorized

Operation

Unit Should Be

Stopped

CA P Emergency: Compres-

sor running without control

authorization.

Compressor is running with

more than 10% RLA and control

is trying to shut it down. Throw

power off to compressor if

unable to stop. Determine cause

before repowering.

Potential Freeze-

up

Evap Press/Temp

Too Low

ERT Emergency: Freeze-up

prevention.

Determine cause. If pumping

refrigerant out of machine, stop

operation and go over pumpout

procedures.

Failure To Stop

Disconnect Power RUN AUX Emergency: DIS-

CONNECT POWER.

Starter and run and start con-

tacts are energized while control

tried to shut down. Disconnect

power to starter.

Loss Of

Communciation

With Starter Loss of Communication with

Starter: Check machine.

Check wiring from PSIO to

SMM. Check SMM module trou-

bleshooting procedures.

Starter Contact

Fault

Abnormal 1CR or Run

Aux

1CR AUX Starter Contact

Fault: Check 1CR/1M aux.

contacts.

Starter run and start contacts

energized while machine was

off. Disconnect power.

Potential Freeze

Up

Cond Press/Temp

Too Low

CRT [VALUE] exceeded limit

of [LIMIT]* Emergency:

Freeze-up prevention.

The condenser pressure trans-

ducer is reading a pressure that

could freeze the water in the

condenser tubes. Check for con-

denser refrigerant leaks, bad

transducers, or transferred

refrigerant. Place the unit in

Pumpdown mode to eliminate

ALARM if vessel is evacuated.