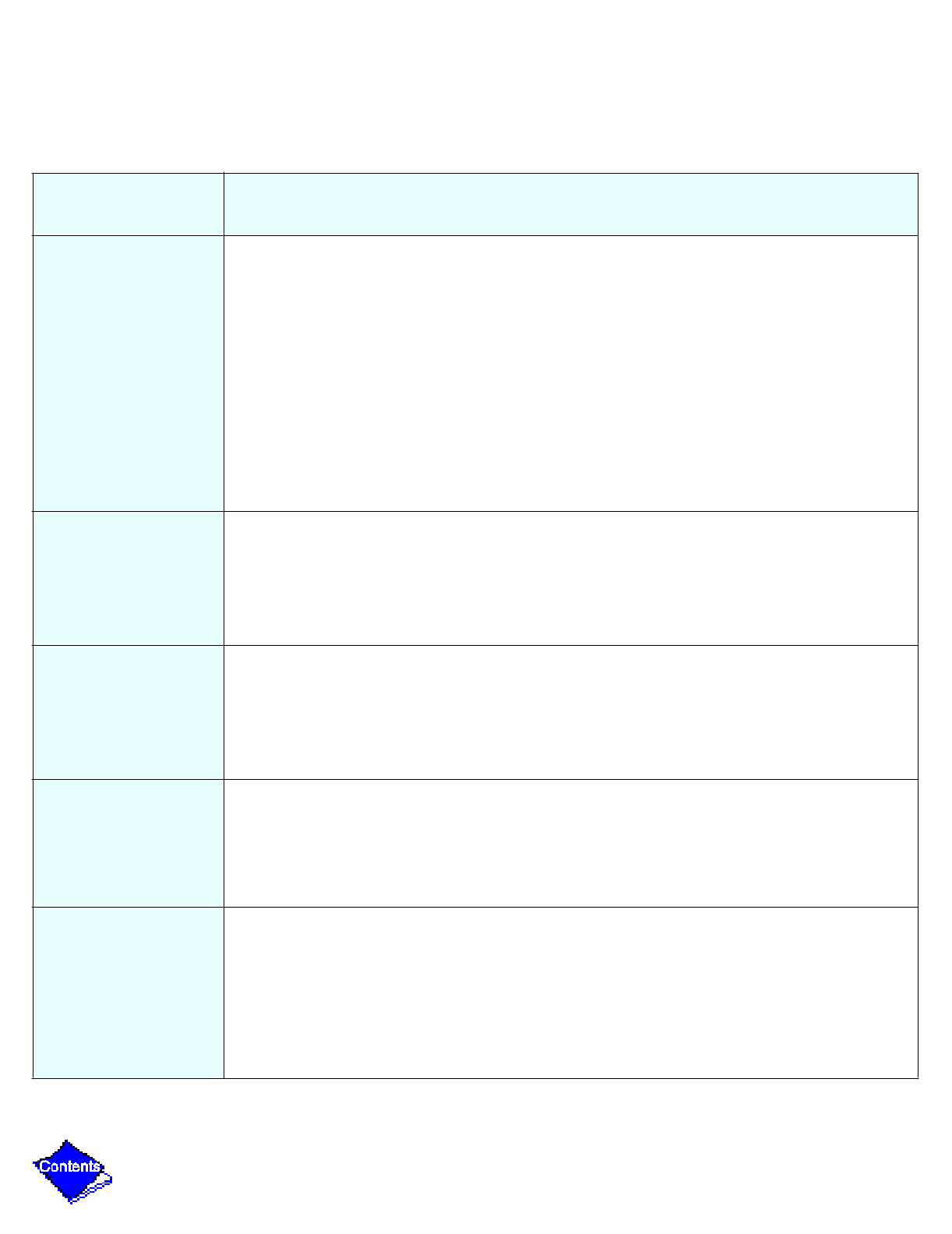

Table 10N — Other Problems/Malfunctions

Description/

Malfunction

Probable Cause/Remedy

Chilled Water/Brine

Temperature Too

High (Machine

Running)

Chilled water set point set too high. Access set point on LID and verify.

Capacity override or excessive cooling load (machine at design capacity). Check

LID status messages. Check for outside air infiltration into conditioned space.

Condenser temperature too high. Check for proper flow, examine cooling tower

operation, check for air or water leaks, check for fouled tubes.

Refrigerant level low. Check for leaks, add refrigerant, and trim charge.

Liquid bypass in waterbox. Examine division plates and gaskets for leaks.

Guide vanes fail to open. Use Control Test to check operation.

Chilled water control point too high. Access control algorithm status and check

chilled water control operation.

Guide vanes fail to open fully. Be sure that the guide vane target is released.

Check guide vane linkage. Check limit switch in actuator. Check that sensor is in

the proper terminals.

Chilled Water/Brine

Temperature Too

Low (Machine

Running)

Chilled water set point set too low. Access set point on LID and verify.

Chilled water control point too low. Access control algorithm status and check

chilled water control for proper resets.

High discharge temperature keeps guide vanes open.

Guide vanes fail to close. Be sure that guide vane target is released. Check chilled

water sensor accuracy. Check guide vane linkage. Check actuator operation.

Chilled Water

Temperature

Fluctuates. Vanes

Hunt

Deadband too narrow. Configure LID for a larger deadband.

Proportional bands too narrow. Either INC or DEC proportional bands should be

increased.

Loose guide vane drive. Adjust chain drive.

Defective vane actuator. Check through Control Test.

Defective temperature sensor. Check sensor accuracy.

Low Oil Sump

Temperature

While Running

(Less than 100 F

[38 C])

Check for proper oil level (not enough oil). Check for proper refrigerant level (too

much refrigerant).

At Power Up,

Default Screen

Does Not Appear,

‘‘Tables Loading’’

Message

Continually

Appears

Check for proper communications wiring on PSIO module. Check that the COMM1

communications wires from the LID are terminated to the COMM1 PSIO connec-

tion.