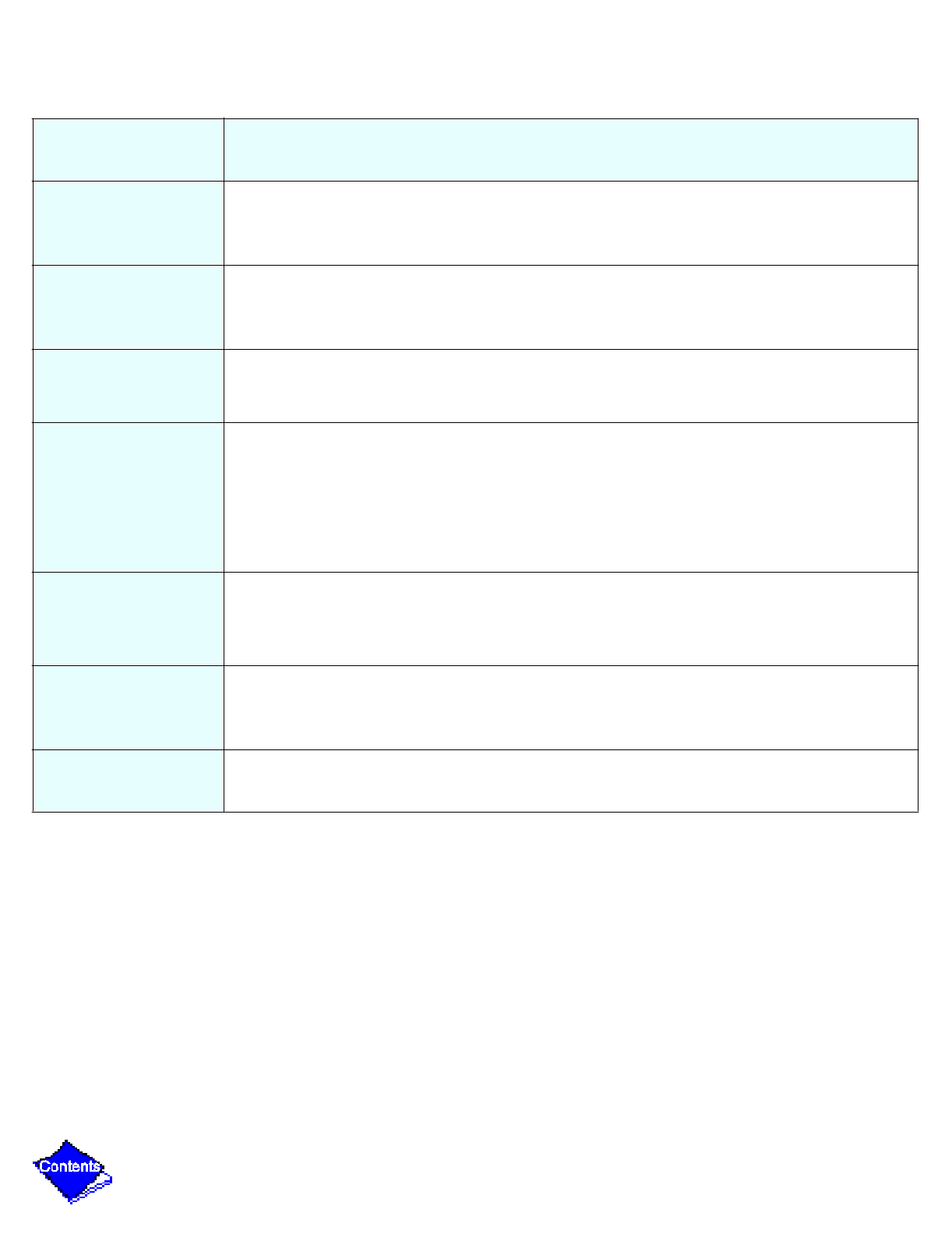

SMM

Communications

Failure

Check that PSIO communication plugs are connected correctly. Check SMM com-

munication plug. Check for proper SMM power supply. See Control Modules sec-

tion.

High Oil

Temperature

While Running

Check for proper oil level (too much oil). Check that TXV valve is operating prop-

erly.

Blank LID Screen

Increase contrast potentiometer. See Figure 42. Check red LED on LID for proper

operation, (power supply). If LED is blinking, but green LED’s are not, replace LID

module, (memory failure).

‘‘Communications

Failure’’

Highlighted

Message At

Bottom of LID

Screen

LID is not properly addressed to the PSIO. Make sure that ‘‘Attach to Network

Device,’’ ‘‘Local Device’’ is set to read the PSIO address. Check LED’s on PSIO. Is

red LED operating properly? Are green LED’s blinking? See control module trou-

bleshooting section.

Controls Test

Disabled

Press the ‘‘Stop’’ pushbutton. The PIC must be in the OFF mode for the controls

test to operate. Clear all alarms. Check line voltage percent on Status01 screen.

The percent must be within 90% to 110%. Check voltage input to SMM, calibrate

starter voltage potentiometer for accuracy.

Vanes Will Not

Open In Control

Test

Low pressure alarm is active. Put machine into pumpdown mode or equalize pres-

sure. Check guide vane actuator wiring.

Oil Pump Does

Not Run

Check oil pump voltage supply. Cooler vessel pressure under vacuum. Pressurize

vessel. Check temperature overload cutout switch.

Table 10N — Other Problems/Malfunctions (Continued)

Description/

Malfunction

Probable Cause/Remedy