46

326142000

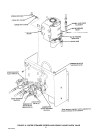

4. Remove right-hand side panel as instructed for access to No. 2 product blender tank product shutoff valve.

5. Close No. 2 product blender tank product shutoff valve to prevent product bleeding back into No. 1 product

blender tank during sanitizing procedure.

IMPORTANT: The following CO

2

and liquid disconnects disconnecting and connecting procedure for

soft drink tank replacement or filling soft drink tank in place must be performed in order as follows:

To disconnect soft drink tank from Unit syrup system.

A. Disconnect liquid disconnect soft drink tank. NOTE - Disconnecting liquid quick disconnect

from soft drink tank first prevents syrup from backflowing through Unit syrup flow regulator

which may alter regulator adjustments.

B. Second, disconnect CO

2

quick disconnect from soft drink tank.

To connect soft drink tank into Unit syrup system.

C. First, connect CO

2

quick disconnect to soft drink tank to pressurize tank.

D. Second, connect liquid quick disconnect to soft drink tank.

6. Disconnect soft drink tank containing syrup from No. 1 syrup system.

7. Connect clean empty soft drink tank into No. 1 syrup system.

8. Place waste container under No. 1 cylinder dispensing valve nozzle. Open dispensing valve and dispense

all product from cylinder. As product level lowers in cylinder, partially close valve to avoid spurting.

9. Remove Unit front lower access panel as instructed for access to No. 1 product blender tank product

sample valve.

10. Place waste container under No. 1 product blender tank product sample valve. Slowly open valve and

purge remaining product out of tank, then close valve.

11. Disconnect empty soft drink tank from No. 1 syrup system.

12. Refer to DISPENSING VALVES CAGED O-RINGS AND DRIVE SHAFTS SEALS ASSEMBLIES under

LUBRICATION and perform procedure to lubricate dispensing valve caged O-ring and drive shaft seal

assembly.

WARNING: To avoid possible injury or property damage, do not attempt to remove soft

drink tank cover until CO

2

pressure has been released from tank.

13. Pull up on empty soft drink tank cover relief valve to release CO

2

pressure from tank.

WARNING: If powder type sanitizer is used, it must be thoroughly dissolved with water

prior to adding to soft drink tank.

NOTE: Sanitizing solution is used in a more concentrated form because it will be diluted approximately

four-to-one in product blender tank.

14. Using clean empty soft drink tank, prepare full tank of sanitizing solution using Chlor-Tergent (Oakite

Product, Inc.) or equivalent sanitizer. Mix sanitizing solution by using 70° F to 100° F (max) plain water and

2.65 oz./gallon sanitizer. This mixture will provide 800-ppm of chlorine. Sanitizing solution will be diluted to

approximately 200-ppm inside product blender tank after carbonated water has been mixed with sanitizing

solution.

15. Shake sanitizing solution tank to thoroughly mix solution, then connect tank into No. 1 syrup system.

16. Press ‘‘FILL 1’’ switch to fill No. 1 syrup system syrup float switch with sanitizing solution ‘‘SYRUP 1’’ fault

message on message display will go out indicating syrup float switch has been filled with sanitizing

solution.