48

326142000

36. After carbonator water pump cycles off, intermittently pull and release No. 1 freeze cylinder faceplate relief

valve. This bleeds CO

2

from freeze cylinder and allows product to enter and fill cylinder.

37. Open No. 2 product blender tank product shutoff valve.

38. Press both ‘‘AUTO 1’’ and ‘‘AUTO 2‘’ switches to start both freeze cylinders beaters and refrigeration

system. Product will be ready for dispensing in approximately 10-minutes.

39. Install right-hand side panel and front lower access panel by reversing removal procedure.

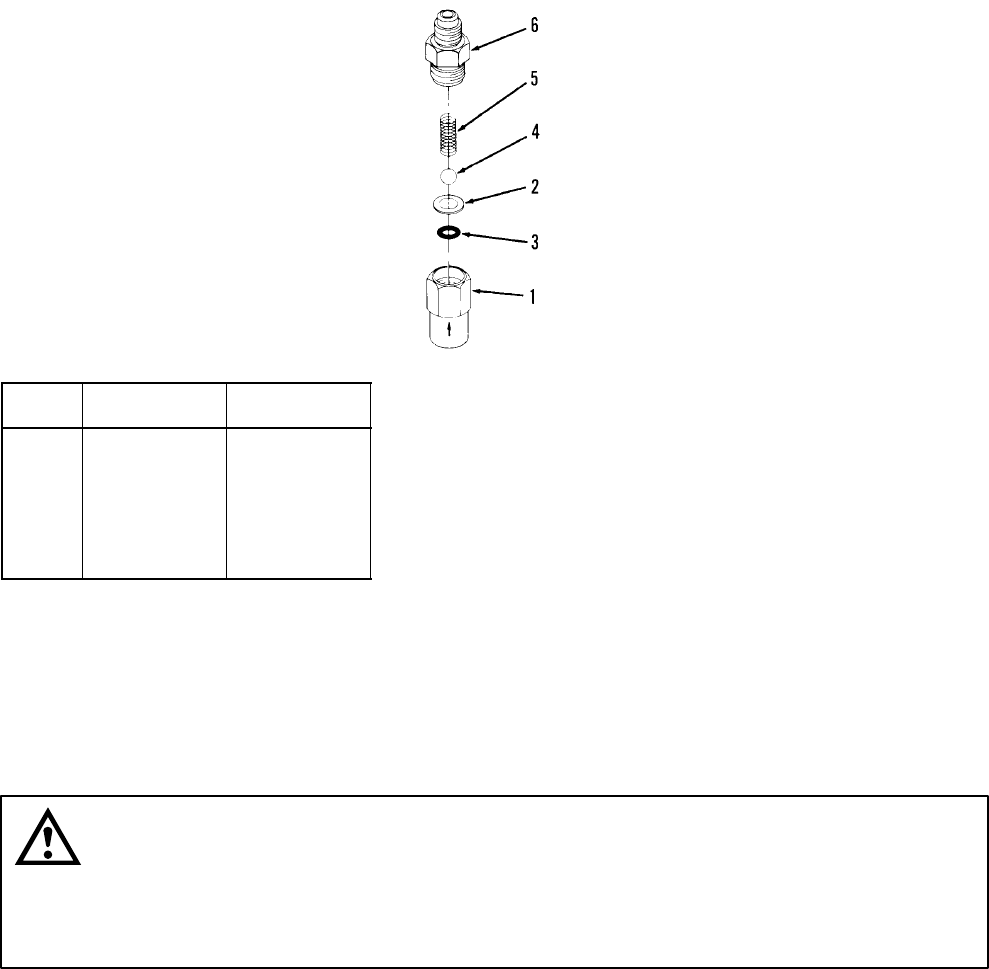

INDEX

NO

PART

NO NAME

1 317965000 Retainer

2 312196000 Spring

3 312419000 Ball

4 312415000 Washer, .300 I.D.

5 312418000 Quad Ring

6 317963000 Body

*Install new ball seat each servicing.

FIGURE 11. LIQUID CHECK VALVE ASSEMBLY

YEARLY OR AFTER WATER SYSTEM DISRUPTION)

WARNING: The carbonator water pump water strainer screen and double liquid check

valve must be Inspected and serviced after any disruptions (plumbing work, earthquake,

etc.) to the water supply system, and at least once a year under normal circumstances,

Water pump with no strainer screen or defective screen would allow foreign particles to foul the

double liquid check valves. CO

2

gas could then back flow into water system and create health

hazard in water system.

SERVICING CARBONATOR WATER PUMP WATER STRAINER SCREEN

(see Figure 12)

1. Press ‘‘OFF 1’’ and ‘‘OFF 2’’ switches to stop freeze cylinders beaters and refrigeration systems.

2. Disconnect electrical power from Unit.

3. Close CO

2

cylinder and water inlet supply line shutoff valve.