53 326142000

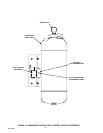

CLEANING CO

2

GAS CHECK VALVES

(see Figures 2 and 13)

The CO

2

gas check valves must be inspected and serviced at least once a year under normal conditions and

after any servicing or disruption of the CO

2

system. ALWAYS REPLACE QUAD RING SEAL EACH TIME GAS

CHECK VALVES ARE SERVICED.

FIGURE 13. CO

2

GAS CHECK VALVE

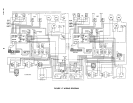

REPLACING FREEZE CYLINDER BEATER DRIVE SHAFT BEARING

(see Figures 3, 8, and 14)

SHUTTING UNIT DOWN

1. Press ‘‘DEFROST’’ switch to defrost product in freeze cylinders.

2. After defrost cycle is completed, press ‘‘OFF 1’’ and ‘‘OFF 2’’ control switches to stop refrigeration system

beaters motors.

3. Disconnect electrical power to Unit.

4. Remove back and side panels as instructed.

5. Close product shutoff valve leading from product blender tank to freeze cylinder beater drive shaft will be

removed from.

6. Drain product from freeze cylinder.

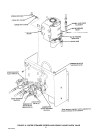

REMOVING BEATER DRIVE MOTOR AND BEATER DRIVE SHAFT ASS’Y FROM UNIT

1. Remove access cover plate from back of beater drive motor for access to motor electrical terminals.

2. Tag motor electrical wiring for identification, then disconnect wiring from motor terminals,

3. Remove bolts and lockwashers securing beater drive motor to Unit frame.

4. Very carefully, remove beater drive motor from Unit. BE CAREFUL NOT TO LOSE PLASTIC COUPLER

LOCATED BETWEEN BEATER DRIVE MOTOR SHAFT COUPLING AND BEATER DRIVE SHAFT

ASSEMBLY COUPLING.