20

MINUTES LEFT FOR START — This value is displayed

only in the network display tables (using Service Tool,

ComfortVIEW™ or ComfortWORKS® software) and

represents the amount of time to elapse before the unit will start

its initialization routine. This value can be zero without the

machine running in many situations. This can include being

unoccupied, ENABLE/OFF/REMOTE CONTACT switch in

the OFF position, SCN not allowing unit to start, Demand

Limit in effect, no call for cooling due to no load, and alarm or

alert conditions present. If the machine should be running and

none of the above are true, a minimum off time (DELY, see

below) may be in effect. The machine should start normally

once the time limit has expired.

MINUTES OFF TIME (DELY) [Configuration OPT2] —

This user-configurable time period is used by the control to

determine how long unit operation is delayed after power is

applied/restored to the unit. Typically, this time period is con-

figured when multiple machines are located on a single site.

For example, this gives the user the ability to prevent all the

units from restarting at once after a power failure. A value of

zero for this variable does not mean that the unit should be

running.

LEAD/LAG DETERMINATION — This is a configurable

choice and is factory set to be automatic for all units. The value

can be changed to Circuit A or Circuit B leading as desired. Set

at automatic, the control will sum the current number of logged

circuit starts and one-quarter of the current operating hours for

each circuit. The circuit with the lowest sum is started first.

Changes to which circuit is the lead circuit and which is the lag

are also made when total machine capacity is at 100% or when

there is a change in the direction of capacity (increase or

decrease) and each circuit’s capacity is equal.

CAPACITY CONTROL OVERRIDES — The following over-

rides will modify the normal operation of the routine.

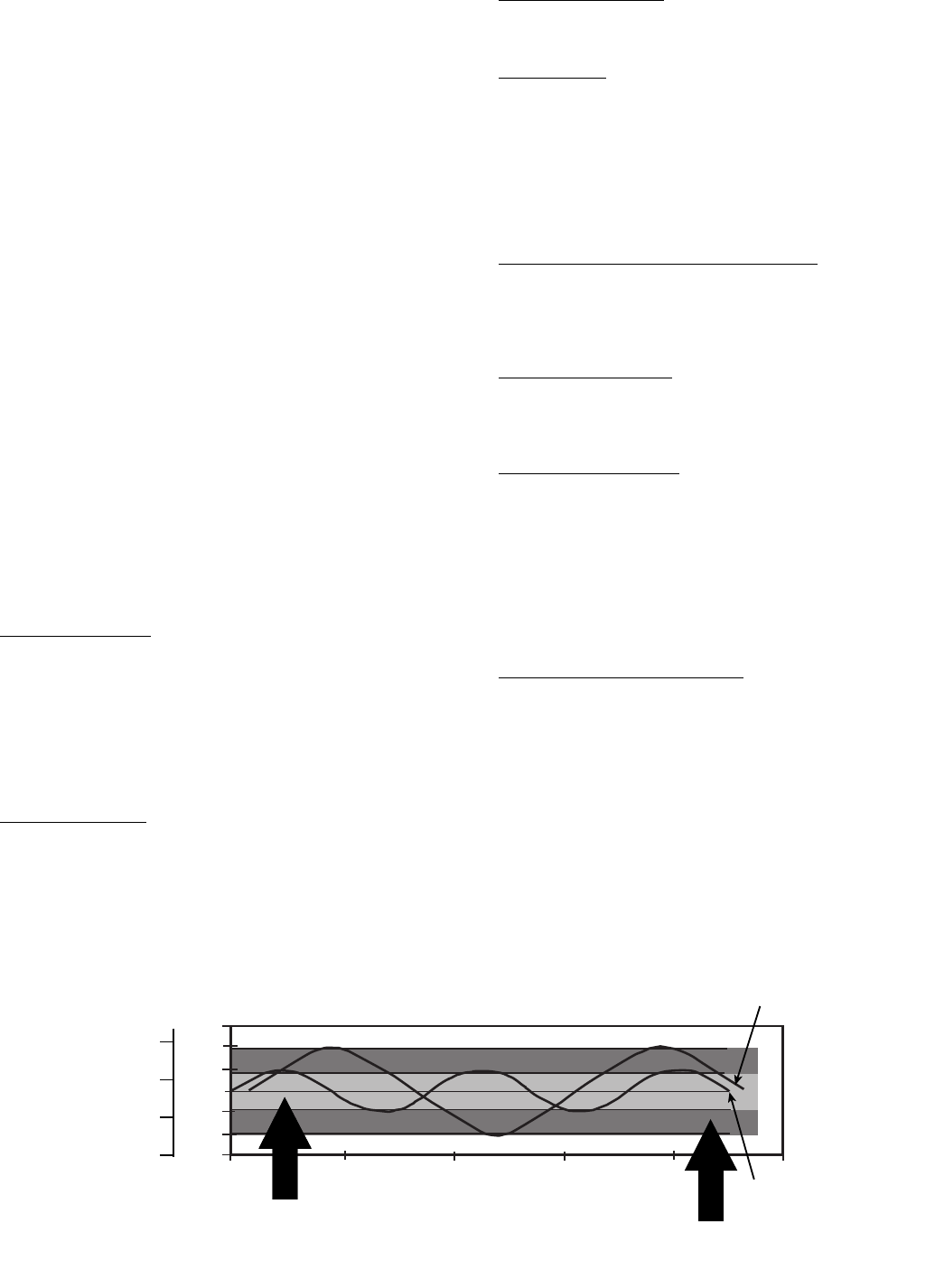

Deadband Multiplier

— The user configurable Deadband

Multiplier (Z.GN) [Configuration, SLCT] has a default value

of 1.0. The range is from 1.0 to 4.0. When set to other than 1.0,

this factor is applied to the capacity Load/Unload Factor. The

larger this value is set, the longer the control will delay between

adding or removing stages of capacity. Figure 12 shows how

compressor starts can be reduced over time if the leaving water

temperature is allowed to drift a larger amount above and be-

low the set point. This value should be set in the range of 3.0 to

4.0 for systems with small loop volumes.

First Stage Override

— If the current capacity stage is zero,

the control will modify the routine with a 1.2 factor on adding

the first stage to reduce cycling. This factor is also applied

when the control is attempting to remove the last stage of

capacity.

Slow Change Override

— The control prevents the capacity

stages from being changed when the leaving fluid temperature

is close to the set point (within an adjustable deadband) and

moving towards the set point.

Ramp Loading

(CRMP) [Configuration, SLCT] — Limits the

rate of change of leaving fluid temperature. If the unit is in a

Cooling mode and configured for Ramp Loading, the control

makes 2 comparisons before deciding to change stages of ca-

pacity. The control calculates a temperature difference between

the control point and leaving fluid temperature. If the differ-

ence is greater than 4 °F (2.2 °C) and the rate of change (°F or

°C per minute) is more than the configured Cooling Ramp

Loading value (CRMP), the control does not allow any chang-

es to the current stage of capacity.

Low Entering Fluid Temperature Unloading

— When the

entering fluid temperature is below the control point, the

control will attempt to remove 25% of the current stages being

used. If exactly 25% cannot be removed, the control removes

an amount greater than 25% but no more than necessary. The

lowest stage will not be removed.

Minimum Load Control

— If equipped, the minimum load

control valve is energized only when one compressor in the

circuit is running. If the close control feature is enabled the

minimum load control valve may be used as needed to obtain

leaving fluid temperature close to set point.

Cooler Freeze Protection

— The control will try to prevent

shutting the chiller down on a Cooler Freeze Protection alarm

by removing stages of capacity. If the cooler fluid selected

is Water, the freeze point is 34 F (1.1 C). If the cooler fluid

selected is Brine, the freeze point is the Brine freeze Point

(BR.FZ) [Set Points, FRZ]. This alarm condition (A207) only

references leaving fluid temperature and NOT Brine Freeze

point. If the cooler leaving fluid temperature is less than the

freeze point plus 2.0° F (1.1° C), the control will immediately

remove one stage of capacity. This can be repeated once every

30 seconds.

Low Saturated Suction Protection

— The control will try to

prevent shutting a circuit down due to low saturated suction

conditions by removing stages of capacity. These circuit alert

conditions (T116, T117) compare saturated suction tempera-

ture to the configured Brine Freeze point (BR.FZ) [Set Points,

FRZ]. The Brine Freeze point is a user-configurable value that

must be left at 34 F (1.1 C) for 100% water systems. A lower

value may be entered for systems with brine solutions, but this

value should be set according to the freeze protection level of

the brine mixture. Failure to properly set this brine freeze point

value may permanently damage the brazed plate heat exchang-

er. The control will initiate Mode 7 (Circuit A) or Mode 8 (Cir-

cuit B) to indicate a circuit’s capacity is limited and that even-

tually the circuit may shut down.

47

46

45

44

43

42

41

0 200 400 600 800 1000

TIME (SECONDS)

2 STARTS

3 STARTS

DEADBAND EXAMPLE

LWT (F)

MODIFIED

DEADBAND

STANDARD

DEADBAND

8

7

6

5

LWT (C)

LEGEND

LWT —

Leaving Water Temperature

Fig. 12 — Deadband Multiplier