54

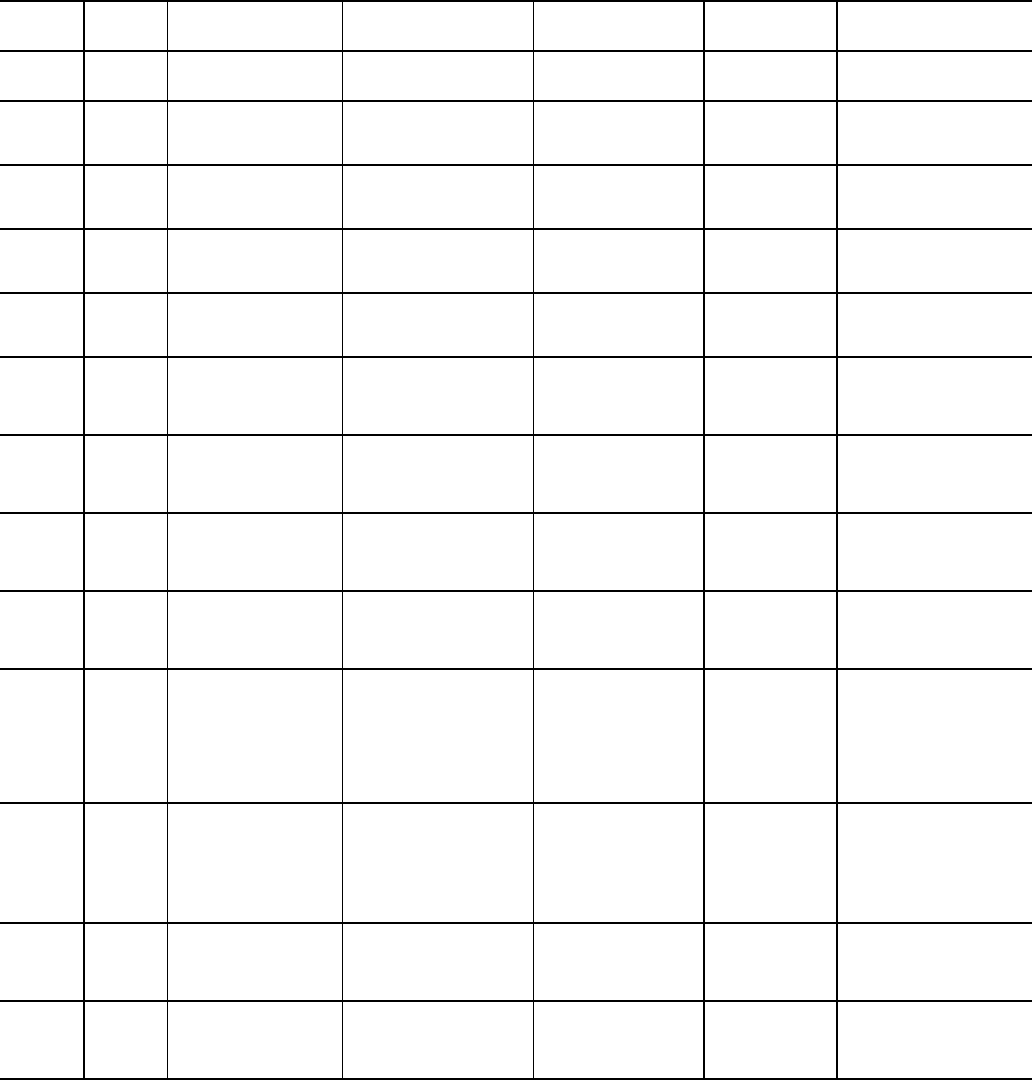

Table 29 — Alarm and Alert Codes (cont)

ALARM/

ALERT

CODE

ALARM

OR

ALERT

DESCRIPTION

WHY WAS THIS

ALARM

GENERATED?

ACTION TAKEN

BY CONTROL

RESET

METHOD

PROBABLE

CAUSE

T093 Alert Circuit B Suction

Pressure Transducer

Failure

Voltage ratio more than

99.9% or less than .5%.

Circuit B shut down Automatic Transducer failure, poor

connection to MBB, or wiring

damage/error.

T110 Alert Circuit A Loss of Charge If the compressors are off

and discharge pressure

reading is < 10 psig for

30 sec.

Circuit not allowed to

start.

Manual Refrigerant leak or

transducer failure

T111 Alert Circuit B Loss of Charge If the compressors are off

and discharge pressure

reading is < 10 psig for

30 sec.

Circuit not allowed to

start.

Manual Refrigerant leak or

transducer failure

T112 Alert Circuit A High Saturated

Suction Temperature

Circuit saturated suction

temperature pressure

transducer > 60 F (15.6 C)

for 5 minutes

Circuit shut down Manual Faulty Expansion valve,

faulty suction pressure

transducer or high entering

fluid temperature.

T113 Alert Circuit B High Saturated

Suction Temperature

Circuit saturated suction

temperature pressure

transducer > 60 F (15.6 C)

for 5 minutes

Circuit shut down Manual Faulty Expansion valve,

faulty suction pressure

transducer or high entering

fluid temperature.

T114 Alert Circuit A Low Suction

Superheat

Return gas sensor enabled

and suction superheat is

more than 10° F (5.6 C)

below the suction superheat

set point for 5 minutes.

Circuit A shut down after

pumpdown complete.

Automatic restart

after first daily

occurrence.

Manual restart

thereafter.

Faulty expansion valve,

faulty suction pressure

transducer, faulty suction gas

thermistor, circuit

overcharged

T115 Alert Circuit B Low Suction

Superheat

Return gas sensor enabled

and suction superheat is

more than 10° F (5.6 C)

below the suction superheat

set point for 5 minutes.

Circuit B shut down after

pumpdown complete.

Automatic restart

after first daily

occurrence.

Manual restart

thereafter.

Faulty expansion valve,

faulty suction pressure

transducer, faulty suction

gas thermistor, circuit

overcharged

T116 Alert Circuit A Low Cooler

Suction Temperature

Mode 7 caused the com-

pressor to unload 6 consecu-

tive times with less than a

30-minute interval between

each circuit shutdown.

Circuit shut down Manual Faulty expansion valve, low

refrigerant charge, plugged

filter drier, faulty suction

pressure transducer, low

cooler fluid flow

T117 Alert Circuit B Low Cooler

Suction Temperature

Mode 8 caused the com-

pressor to unload 6 consecu-

tive times with less than a

30-minute interval between

each circuit shutdown.

Circuit shut down Manual Faulty expansion valve, low

refrigerant charge, plugged

filter drier, faulty suction

pressure transducer, low

cooler fluid flow

T126 Alert Circuit A High

Discharge Pressure

SCT >Maximum condensing

temperature from operating

envelope

Circuit shut down Automatic, only

after first 3 daily

occurrences.

Manual reset

thereafter. Read-

ing from OAT sen-

sor (T9) must drop

5 F (2.8 C) before

restart

Faulty transducer/high

pressure switch, low/

restricted condenser

airflow

T127 Alert Circuit B High

Discharge Pressure

SCT >Maximum condensing

temperature from operating

envelope

Circuit shut down Automatic, only

after first 3 daily

occurrences. Man-

ual reset thereafter.

Reading from OAT

sensor (T9) must

drop 5 F (2.8 C)

before restart

Faulty transducer/high

pressure switch, low/

restricted condenser

airflow

T133 Alert Circuit A Low Suction

Pressure

Suction pressure below

15 psig for 8 seconds or

below 8 psig

Circuit shut down Automatic

restart after first

daily occurrence.

Manual restart

thereafter.

Faulty or plugged TXV, low

refrigerant charge, TXV out

of adjustment, liquid

line valve partially closed

T134 Alert Circuit B Low Suction

Pressure

Suction pressure below

15 psig for 8 seconds or

below 8 psig

Circuit shut down Automatic

restart after first

daily occurrence.

Manual restart

thereafter.

Faulty or plugged TXV, low

refrigerant charge, TXV out

of adjustment, liquid

line valve partially closed