62

The amount of capacity reduction achieved by the mini-

mum load valve is not adjustable. The total unit capacity with

the minimum load valve is shown in Table 7.

PRESSURE RELIEF DEVICES — All units have one pres-

sure relief device per circuit located in the liquid line which re-

lieves at 210 F (100 C).

Compressor and Unit Protective Devices

MANUAL STARTER — There is one manual starter per

compressor in each unit. It protects the compressor(s) against

overloading, locked rotor conditions, and primary single phas-

ing. If the manual starter trips, determine the cause and correct

it before resetting.

Manual starters are factory set; field adjustment should not

be required. Manual starters are also factory installed for each

condenser fan motor and factory-installed chilled water pump.

NOTE: Two-speed condenser fan motors on sizes 010-018 and

032-040 have manual starters so that the motor is protected

while running in both low and high speed modes. Refer to

Appendix B for factory settings.

COMPRESSOR INTERNAL THERMAL PROTECTION —

All models include internal compressor protection. Models

using the SM110 compressor (015 50 Hz and 018 60 Hz) have

internal line break overloads. All other compressor models

have internal discharge temperature thermostats that are wired

in series with the compressor high pressure switch in the com-

pressor motor junction box. The thermostat opens and shuts off

the compressor if the discharge gas temperature exceeds 275 F

(135 C). The thermostat will automatically reset when the tem-

perature drops below a preset level, however, the control mod-

ule will keep the unit locked off until the alert condition is

reset.

Check Unit Safeties

HIGH-PRESSURE SWITCH — A high-pressure switch is

provided to protect each compressor and refrigeration system

from unsafe high pressure conditions. See Table 32 for high-

pressure switch settings.

The high-pressure switch is mounted in the discharge side

of each compressor. A snubber is provided between the com-

pressor discharge manifold and the high-pressure switch to pre-

vent pressure pulsations from damaging the switch.

The high-pressure switch is mounted in the discharge line of

each compressor. If an unsafe, high-pressure condition should

exist, the switch opens and shuts off the affected compressor.

The compressor feedback signal to J9 of the MBB then opens

causing an alert condition. The MBB prevents the compressor

from restarting until the alert condition is reset. The switch

should open at the pressure corresponding to the appropriate

switch setting as shown in Table 32.

Table 32 — Factory Settings, High-Pressure

Switch (Fixed)

Clear the alarm using the Scrolling Marquee display as de-

scribed on page 42. The unit should restart after the compressor

anti-short-cycle delay, built into the unit control module,

expires.

PRESSURE TRANSDUCERS — Each refrigerant circuit is

equipped with a suction and discharge pressure transducer. The

transducers are NOT the same part number. The discharge

pressure transducer is the universal pressure transducer while

the suction pressure transducer is a discrete low pressure trans-

ducer. These inputs to the MBB are not only used to monitor

the status of the unit, but to also maintain operation of the chill-

er within the compressor manufacturer's specified limits. The

input to the MBB from the suction pressure transducer is also

used to protect the compressor from operating at low pressure

conditions. In some cases, the unit may not be able to run at full

capacity. The control module will automatically reduce the ca-

pacity of a circuit as needed to maintain specified maximum/

minimum operating pressures.

UNIT

CUTOUT CUT-IN

Psig kPa Psig kPa

30RA

426 ± 7 2937 ± 48 324 ± 20 2206 ± 138

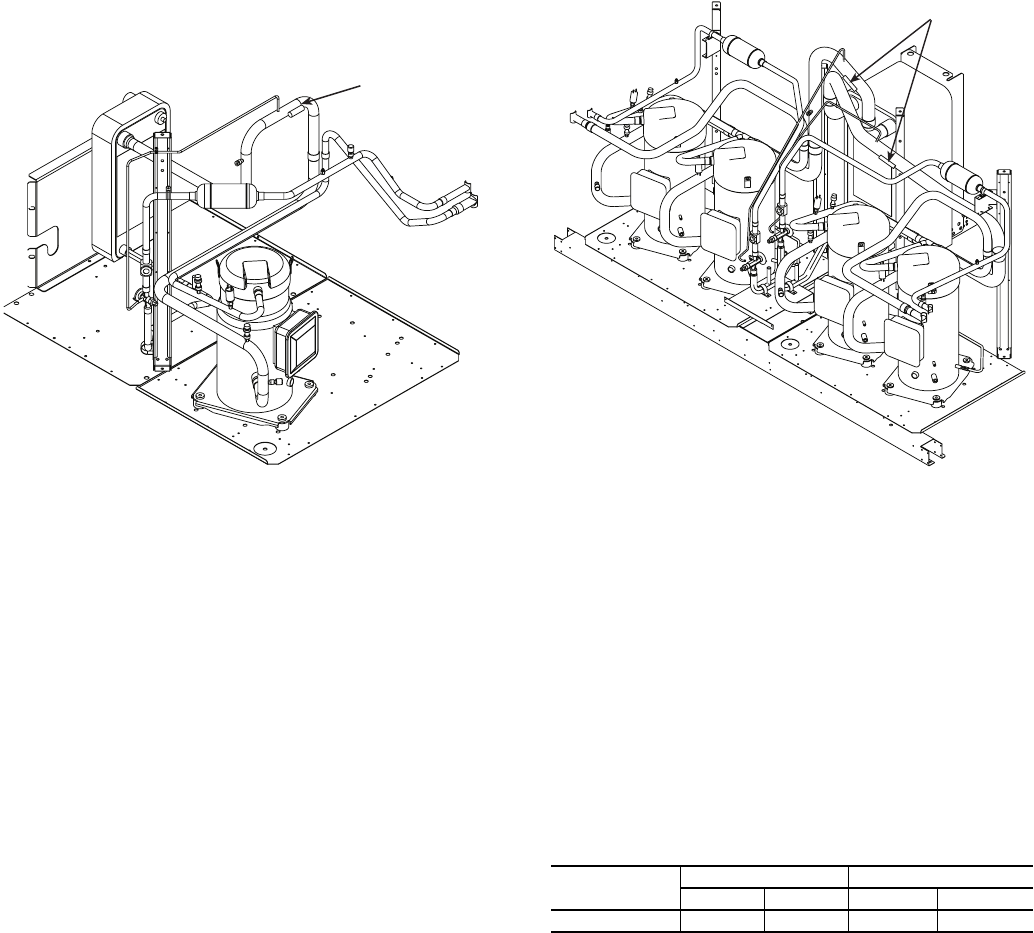

TXV SENSOR

LOCATION

TXV SENSOR

LOCATION

Fig. 34 — Mounting Locations for TXV Sensing Bulb