68

Strainer —

Periodic factory-installed strainer cleaning is

required. Pressure drop across strainer in excess of 3 psi

(21 kPa) indicates the need for cleaning. Normal (clean) pres-

sure drop is approximately 1 psi (6.9 kPa). Open the factory-

installed blowdown valve to clean the strainer. If required, shut

the chiller down and remove the strainer screen to clean. When

strainer has been cleaned, enter ‘YES’ for strainer maintenance

done (S.T.MN) [Run Status, PM].

Motormaster® V Controller —

The optional or ac-

cessory Motormaster V controller uses a 0 to 5 vdc signal

input from a pressure transducer attached to the liquid line ser-

vice valve gage port on each circuit. See Fig. 37. The pressure

transducer is connected to terminals 2, 5 and 6 on the control-

ler. The controller is factory configured and requires no field

programming. If a situation arises where the drive does not

function properly, the information provided below and

Table 37 can be used to troubleshoot the drive.

GENERAL OPERATION — This control varies condenser

fan speed based on liquid pressure. The control is a Variable

Frequency Drive (VFD) and is only compatible with motors

rated for use with VFDs. The accompanying pressure transduc-

er has a 0 to 5 v output range corresponding to a –40 to 460 psi

range. The VFD provides a 5 v output for the transducer on

pin 6.

This system is a reverse acting, proportional-integral (PI)

control. The VFD will vary the motor speed to drive the liquid

line pressure to the set point during ambient temperatures be-

low 60 F. The set point is lower than a normal operating pres-

sure during summer operation. At higher ambient tempera-

tures, the fan will go to full speed (60 Hz or 50 Hz depending

on model) and remain there since it can not go fast enough to

bring the pressure down to the set point. When the VFD is at

full speed, it acts just like a fixed speed fan.

When the ambient air temperature drops, a fan running at

full speed draws too much air across the condenser coil to

maintain a minimum condensing pressure/temperature. In

these conditions, the VFD will slow down and begin to main-

tain a set point.

The VFD will display the set point as the default. The set

point is displayed in speed as Hz and is configured by the start

command jumper as detailed in Fig. 38.

Motormaster V control can also be configured to follow an

external control system to perform the PI control functions. See

configuration section for details.

The real-time feedback signal (liquid line pressure, in volts)

is displayed by viewing parameter 69. The real-time output fre-

quency is displayed by viewing parameter 71.

SET POINTS — Operating modes are configured for R-22

with a set point of 135 psig on the liquid line.

INSTALLATION — See Fig. 38 for transducer wiring to the

VFD.

NOTE: The drive is phase insensitive with respect to incoming

line voltage. This means that the VFD will operate with any

phase sequence of the incoming three-phase voltage.

If input power has not been applied to the drive for a period

of time exceeding three years (due to storage, etc.), the

electrolytic DC bus capacitors within the drive can change

internally, resulting in excessive leakage current. This can

result in premature failure of the capacitors if the drive is

operated after such a long period of inactivity or storage. In

order to reform the capacitors and prepare the drive for

operation after a long period of inactivity, apply input

power to the drive for 8 hours prior to actually operating

the motor. Before attempting to operate the drive, motor,

and driven equipment, be sure all procedures pertaining to

installation and wiring have been properly followed.

DO NOT connect incoming AC power to output terminals

T1, T2, and T3! Severe damage to the drive will result. Do

not continuously cycle input power to the drive more than

once every two minutes. Damage to the drive will result.

Hazard of electrical shock! Wait three minutes after discon-

necting incoming power before servicing drive. Capacitors

retain charge after power is removed. Drive assembly

includes externally mounted current limiting resistors. Use

extreme caution when servicing the drive.

When configured as shown below, this equipment is

designed to start when it receives line power. Ensure that

all personnel are clear of fans and guards are installed

before applying power.

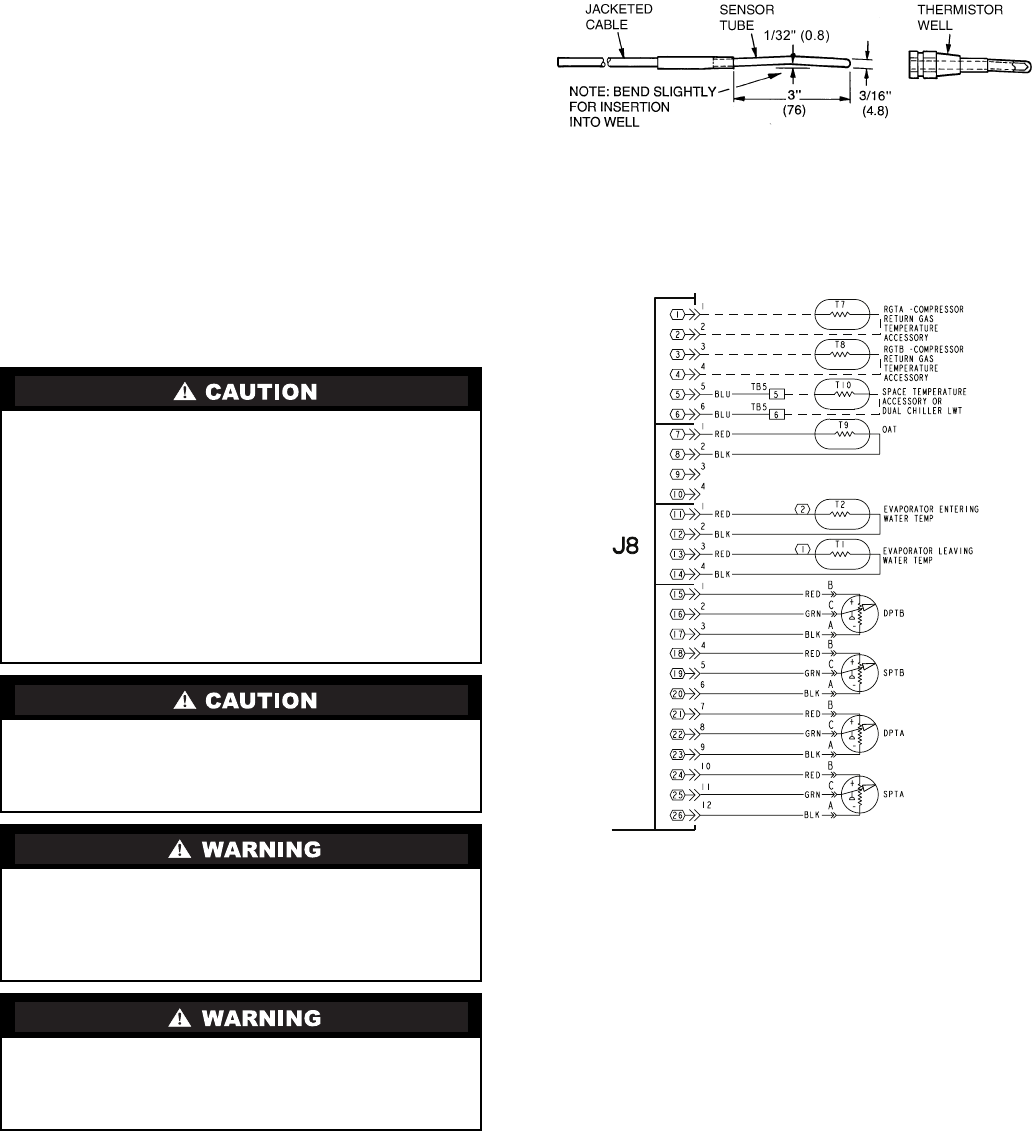

FLUID-SIDE TEMPERATURE SENSORS (T1 AND T2)

NOTE: Dimensions in ( ) are in millimeters.

Fig. 35 — Fluid-Side Temperature Sensors

(T1 and T2)

Fig. 36 — Thermistor Connections to

Main Base Board, J8 Connector