60

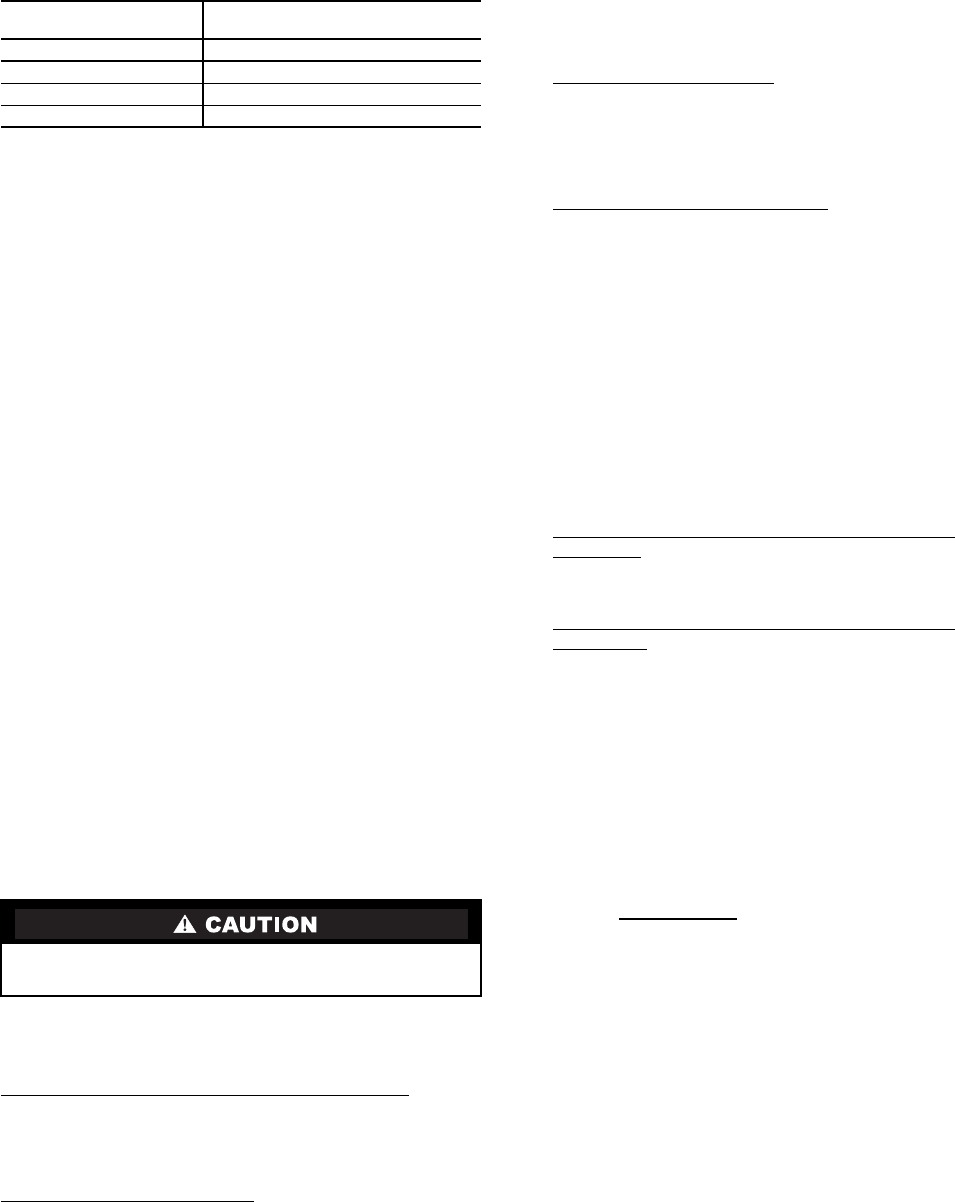

Check Oil Charge —

Compressors are factory charged

with oil as shown in Table 31.

Table 31 — Oil Charge

If oil is visible in the compressor sight glass, check unit for

operating readiness as described in Pre-Start-Up, System

Check section (page 74), then start the unit. Observe oil level

and add oil if required, to bring oil level in compressor

crankcase up to between

1

/

4

and

3

/

4

of sight glass during steady

operation.

To Add Oil:

1. Check the oil level with all compressors in the circuit run-

ning in a stabilized condition or immediately after com-

pressor shutdown. The oil level should be at

1

/

3

of the oil

sight glass immediately after shutdown.

2. Using a suitable pump, add oil while compressor(s) are

running through the low side ¼ in. Schraeder fitting on

the compressor. For SM110 models, this fitting is directly

above the suction line connection. For all other compres-

sor models, this fitting is near the oil equalization line fit-

ting at the same height as the suction line connection.

3. Run all compressors on the circuit for at least 15 minutes

and check the oil level.

Use only Sterling-approved compressor oil:

Totaline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PP680002

Penreco . . . . . . . . . . . . . . . . . . . . . . . . . . . .Sontex 160 LT-A

Do not reuse drained oil, and do not use any oil that has

been exposed to the atmosphere.

Condenser Section and Coils

COIL CLEANING — For standard aluminum, copper and

pre-coated aluminum fin coils, clean the coils with a vacuum

cleaner, fresh water, compressed air, or a bristle brush (not

wire). Units installed in corrosive environments should have

coil cleaning as part of a planned maintenance schedule. In this

type of application, all accumulations of dirt should be cleaned

off the coil. When condenser cleaning is complete, enter “Yes”

for coil cleaning maintenance done (CL.MN) value under Run

Status.

CLEANING E-COATED COILS — Follow the outlined pro-

cedure below for proper care, cleaning and maintenance of

E-coated aluminum or copper fin coils:

Coil Maintenance and Cleaning Recommendations

— Rou-

tine cleaning of coil surfaces is essential to maintain proper

operation of the unit. Elimination of contamination and

removal of harmful residues will greatly increase the life of the

coil and extend the life of the unit.

Remove Surface Loaded Fibers

— Surface loaded fibers or

dirt should be removed with a vacuum cleaner. If a vacuum

cleaner is not available, a soft brush may be used. In either

case, the tool should be applied in the direction of the fins. Coil

surfaces can be easily damaged (fin edges bent over) if the tool

is applied across the fins.

NOTE: Use of a water stream, such as a garden hose, against a

surface loaded coil will drive the fibers and dirt into the coil.

This will make cleaning efforts more difficult. Surface loaded

fibers must be completely removed prior to using low velocity

clean water rinse.

Periodic Clean Water Rinse

— A periodic clean water rinse is

very beneficial for coils that are applied in coastal or industrial

environments. However, it is very important that the water

rinse is made with very low velocity water stream to avoid

damaging the fin edges. Monthly cleaning as described below

is recommended.

Routine Cleaning of Coil Surfaces

— Monthly cleaning with

Environmentally Sound Coil Cleaner is essential to extend the

life of coils. It is recommended that all coils, including stan-

dard aluminum, pre-coated, copper/copper or E-coated coils

are cleaned with the Environmentally Sound Coil Cleaner as

described below. Coil cleaning should be part of the units regu-

larly scheduled maintenance procedures to ensure long life of

the coil. Failure to clean the coils may result in reduced dura-

bility in the environment.

Environmentally Sound Coil Cleaner is non-flammable,

hypo allergenic, non-bacterial, USDA accepted biodegradable

and 100% ecologically safe agent that will not harm the coil or

surrounding components such as electrical wiring, painted

metal surfaces or insulation. Use of non-recommended coil

cleaners is strongly discouraged since coil and unit durability

could be affected.

Environmentally Sound Coil Cleaner Application

Equipment

•2

1

/

2

Gallon Garden Sprayer

• Water Rinse with Low Velocity Spray Nozzle

Environmentally Sound Coil Cleaner Application

Instructions

• Although Environmentally Sound Coil Cleaner is harm-

less to humans, animals, and marine life, proper eye pro-

tection such as safety glasses is recommended during

mixing and application.

• Remove all surface loaded fibers and dirt with a vacuum

cleaner as described above.

• Thoroughly wet finned surfaces with clean water and a

low velocity garden hose being careful not to bend fins.

• Mix Environmentally Sound Coil Cleaner in a 2

1

/

2

gallon

garden sprayer according to the instructions included

with the Enzyme Cleaner. The optimum solution tem-

perature is 100 F.

NOTE: DO NOT USE

water in excess of 130 F as the enzy-

matic activity will be destroyed.

• Thoroughly apply Environmentally Sound Coil Cleaner

solution to all coil surfaces including finned area, tube

sheets and coil headers.

• Hold garden sprayer nozzle close to finned areas and

apply cleaner with a vertical, up-and-down motion.

Avoid spraying in horizontal pattern to minimize poten-

tial for fin damage.

• Ensure cleaner thoroughly penetrates deep into finned

areas.

• Interior and exterior finned areas must be thoroughly

cleaned.

• Finned surfaces should remain wet with cleaning solu-

tion for 10 minutes.

• Ensure surfaces are not allowed to dry before rinsing.

Reapply cleaner as needed to ensure 10-minute satura-

tion is achieved.

COMPRESSOR

AMOUNT

pints (liters)

SM110

5.7 (2.7)

SM115, SM125

6.7 (3.2)

SM160

7.0 (3.3)

SM185

11.6 (5.5)

Do not use high-pressure water or air to clean coils — fin

damage may result.