76

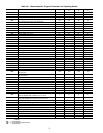

Table 41 — Temperature Limits for

Standard 30RA Units

LEGEND

*For sustained operation, EWT should not exceed 85 F (29.4 C).

†Unit requires modification below this temperature.

LOW-AMBIENT OPERATION — If operating temperatures

below 45 F (7 C) for sizes 010-030 or below 32 F (0° C) for

sizes 032-055 are expected, accessory Motormaster® V con-

trol must be installed. Refer to separate installation instructions

for operation using this accessory. Contact your Sterling repre-

sentative for details.

VOLTAGE — ALL UNITS

Main Power Supply

— Minimum and maximum acceptable

supply voltages are listed in the Installation Instructions.

Unbalanced 3-Phase Supply Voltage — Never operate a motor

where a phase imbalance between phases is greater than 2%.

To determine percent voltage imbalance:

The maximum voltage deviation is the largest difference

between a voltage measurement across 2 legs and the average

across all 3 legs.

Example: Supply voltage is 240-3-60.

AB = 243 v

BC = 236 v

AC = 238 v

1. Determine average voltage:

2. Determine maximum deviation from average voltage:

(AB) 243 – 239 = 4 v

(BC) 239 – 236 = 3 v

(AC) 239 – 238 = 1 v

Maximum deviation is 4 v.

3. Determine percent voltage imbalance:

This voltage imbalance is satisfactory as it is below the

maximum allowable of 2%.

Control Circuit Power

— Power for the control circuit is

supplied from the main incoming power through a factory-

installed control power transformer (TRAN1) for all models.

Field wiring connections are made to either terminal block

TB5 or TB6.

OPERATION SEQUENCE

During unit off cycle, the control monitors the outdoor air

temperature. If the ambient temperature drops below 40 F

(4.4 C), cooler and hydronic system heaters (if either are facto-

ry installed) are energized. If power is maintained to the chiller

and the EMERGENCY ON/OFF switch is left in the OFF po-

sition, these heaters are also energized.

The unit is started by putting the ENABLE/OFF/REMOTE

CONTACT switch in the ENABLE or REMOTE CONTACT

position. When the unit receives a call for cooling (either from

the internal control or SCN network command or remote con-

tact closure), the unit stages up in capacity to maintain the leav-

ing fluid set point. The first compressor starts 1

1

/

2

to 3 minutes

after the call for cooling.

The lead circuit can be specifically designated on all models

or selected based on compressor run hours and starts depend-

ing on field configuration. The unit control will override this

selection under certain starting conditions to properly maintain

oil return to the compressors. In general, on dual compressor

circuits, the control will most often start the A1 or B1 compres-

sor first, especially after long off periods. The MBB controls

fan stages to maintain the head pressure set point and will auto-

matically adjust unit capacity as required to keep compressors

from operating outside of the specified envelope. There are no

pumpout or pumpdown sequences on these chillers.

For all units, if temperature reset is being used, the unit con-

trols to a higher leaving-fluid temperature as the building load

reduces. If demand limit is used, the unit may temporarily be

unable to maintain the desired leaving-fluid temperature be-

cause of imposed power limitations. Loading sequence for

compressors is shown in Tables 6 and 7.

UNIT SIZE 30RA 010-030 032-055

Temperature F C F C

Maximum Ambient

Temperature

120 49 120 49

Minimum Ambient

Temperature

45 7 32 0

Maximum Cooler EWT*

95 35 95 35

Maximum Cooler LWT

70 21 70 21

Minimum Cooler LWT†

40 4.4 40 4.4

EWT —

Entering Fluid (Water) Temperature

LWT —

Leaving Fluid (Water) Temperature

Brine duty application (below 40 F [4.4 C] LCWT) for

chiller normally requires factory modification. Contact

your Sterling representative for applicable LCWT range for

standard water-cooled chiller in a specific application.

% Voltage Imbalance = 100 x

max voltage deviation

from avg voltage

average voltage

Average voltage =

243 + 236 + 238

3

=

717

3

= 239

% Voltage Imbalance = 100 x

4

239

= 1.7%

IMPORTANT: If the supply voltage phase imbalance is

more than 2%, contact your local electric utility company

immediately. Do not operate unit until imbalance condition

is corrected.