10 Chiller System Design and Control SYS-APM001-EN

Primary System Components

pumped all the time; however, in systems with very small water pressure

drops, this system arrangement may work economically.

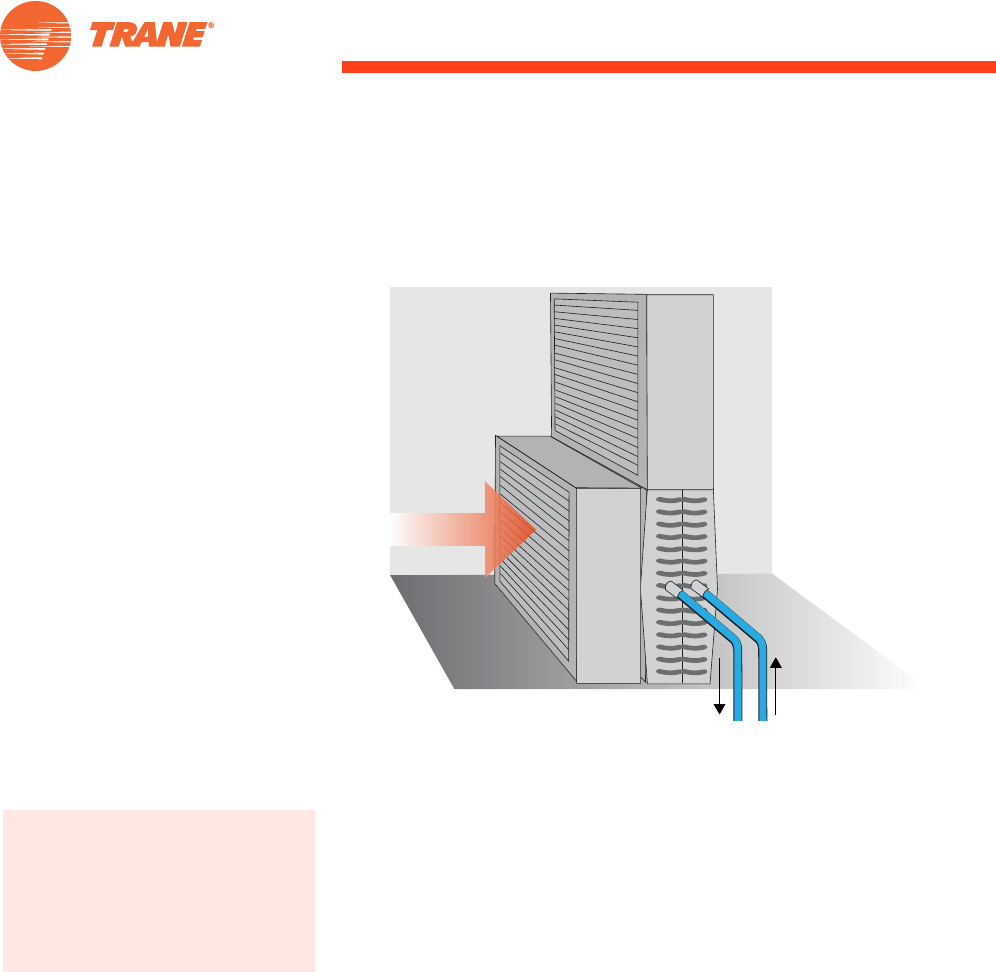

Figure 8. Uncontrolled water flow with bypass damper

Chilled-Water Distribution System

Chilled water is circulated through fixed piping—most commonly steel,

copper, or plastic—that connects the chiller with various load terminals.

Piping is sized to meet pressure loss, water velocity, and construction cost

parameters.

Chilled-water pump

The chilled-water pump creates pressure to circulate chilled water within the

loop. Generally, the pump must overcome the frictional pressure losses

caused by the piping, coils, and chiller and the pressure differential across

open control valves in the system. The pump, while working at the system

static pressure, does not need to overcome this static pressure. For example,

in a forty-story building, the pump need not overcome the static pressure due

to those forty stories.

The chilled-water pump is typically located upstream of the chiller; however,

it may be anywhere in the system, provided that the pump:

• meets the minimum pump net positive suction-head requirements. That

is, the system pressure at the pump inlet must be both positive and high

enough to allow the pump to operate properly;

• maintains the minimum dynamic pressure head at critical system

components (usually the chiller). If the dynamic pressure head is not high

enough at these components, proper flow will not be established through

them;

Bypass

Damper

Face

Damper

Airflow

Additional reference information on the

components of a chilled-water

distribution system is available in the

2008 ASHRAE HVAC Systems and

Equipment Handbook, chapter 12,

“Hydronic Heating and Cooling System

Design.”

3