Primary System Components

SYS-APM001-EN Chiller System Design and Control 11

• accommodates the total pressure (static head plus dynamic head) on

system components such as the chiller’s evaporator, valves, etc.

Note that the pump heat is added to the water and must be absorbed by the

chiller. Generally, this represents a very small temperature increase.

Multiple pumps are often used for redundancy. Depending on the terminal

control devices and system configurations, the chilled-water pumps may be

either constant- or variable-flow.

As previously stated, pumps may be either on the inlet or the outlet of the

chiller, as long as the inlet of the pump experiences an adequate, positive

suction pressure. In applications where there is a significant liquid column

head (for example, a high-rise building), the pump is often located at the

chiller’s outlet so that the evaporator bundle is subject only to the static head

(rather than the static head plus the dynamic head added by the pump). The

need for high-pressure water boxes on the chiller can be eliminated.

Conversely, an advantage of locating the pump at the chiller’s inlet is that if

the pump motor rejects its heat to the water, the heat can be removed directly

by the chiller. The chiller does not need to compensate for the pump heat by

making colder water.

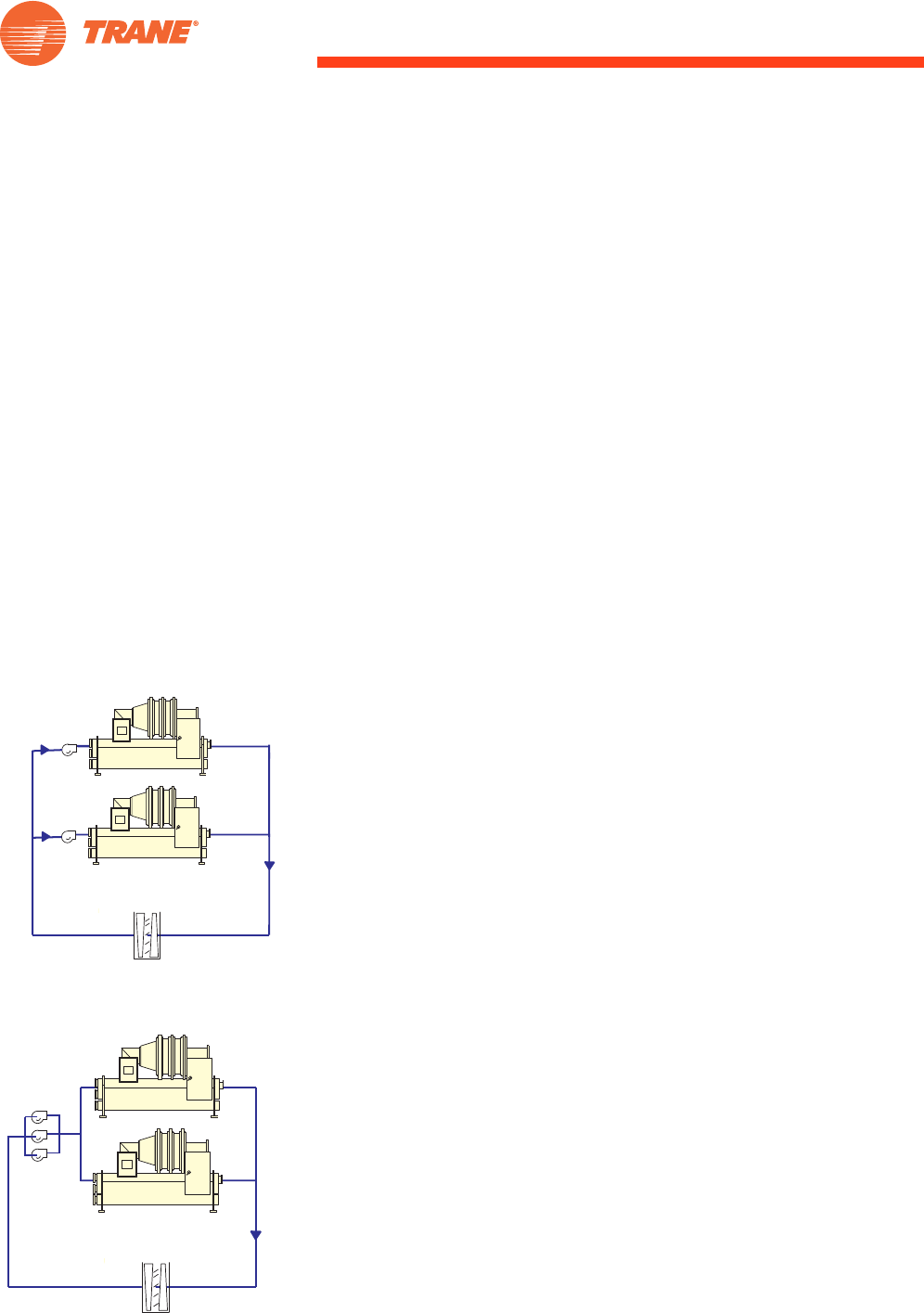

Pump per chiller

In either a primary–secondary or variable-primary-flow system, using one

pump per chiller simplifies system hydraulics (Figure 9). The pump can be

selected to produce the flow and pressure drop necessary for the specific

chiller. Bringing on additional pumps changes system hydraulics, but only

minimally. One drawback of such a system is a lack of redundancy, since the

pump and chiller are dedicated to one another. This may be overcome by

using a spare pump, pipes, and valves so that the spare pump could work

with any chiller during emergency conditions.

Manifolded pumps

In an effort to resolve the redundancy consideration, some designers prefer

to manifold pumps and provide n+1 pumps, where n is the number of chillers

(Figure 10). Such an arrangement allows any pump to be used with any

chiller. However, system hydraulics become more complicated. Unless all

piping runs and evaporator pressure drops are equal, the amount of water

flowing to each chiller will differ. As discussed in “Moderate ’low T

syndrome’" on page 68, manifolded pumps present a control opportunity

when low T is experienced.

Either pump configuration can be successful; one pump per chiller simplifies

the hydraulics, while manifolded pumps allow redundancy.

Distribution piping

By itself, the distribution system is easy to understand. Figure 11 shows a

simplified distribution system consisting of multiple cooling coils, each

controlled by a thermostat that regulates the flow in its respective coil. The

Figure 9. Pump per chiller

Load

Pump

Pump

Figure 10. Manifolded pumps

Manifolded

Pumps

Load