84 Chiller System Design and Control SYS-APM001-EN

System Issues and Challenges

Retrofit Opportunities

A tremendous retrofit opportunity can be realized if the low-flow concepts

discussed in the chapter “System Design Options” on page 27 are utilized.

Building owners may need to increase the capacity of an existing system, for

example, in response to a building addition. In many of these buildings, the

condenser water system (piping, pump, and tower) is in good condition, but

is considered to be too small. By changing from traditional design conditions,

the existing infrastructure can often be used while still providing additional

capacity. A detailed discussion of this starts on page 37.

Applications Outside the Chiller’s Range

Designers may wish to use chillers to provide cooling for which the flow rate

or temperature requirements are not within the allowable ranges of a

particular chiller, even though the chiller has adequate capacity. This often

occurs with manufacturing processes. Let’s look at two examples showing

system designs that can satisfy the desired conditions.

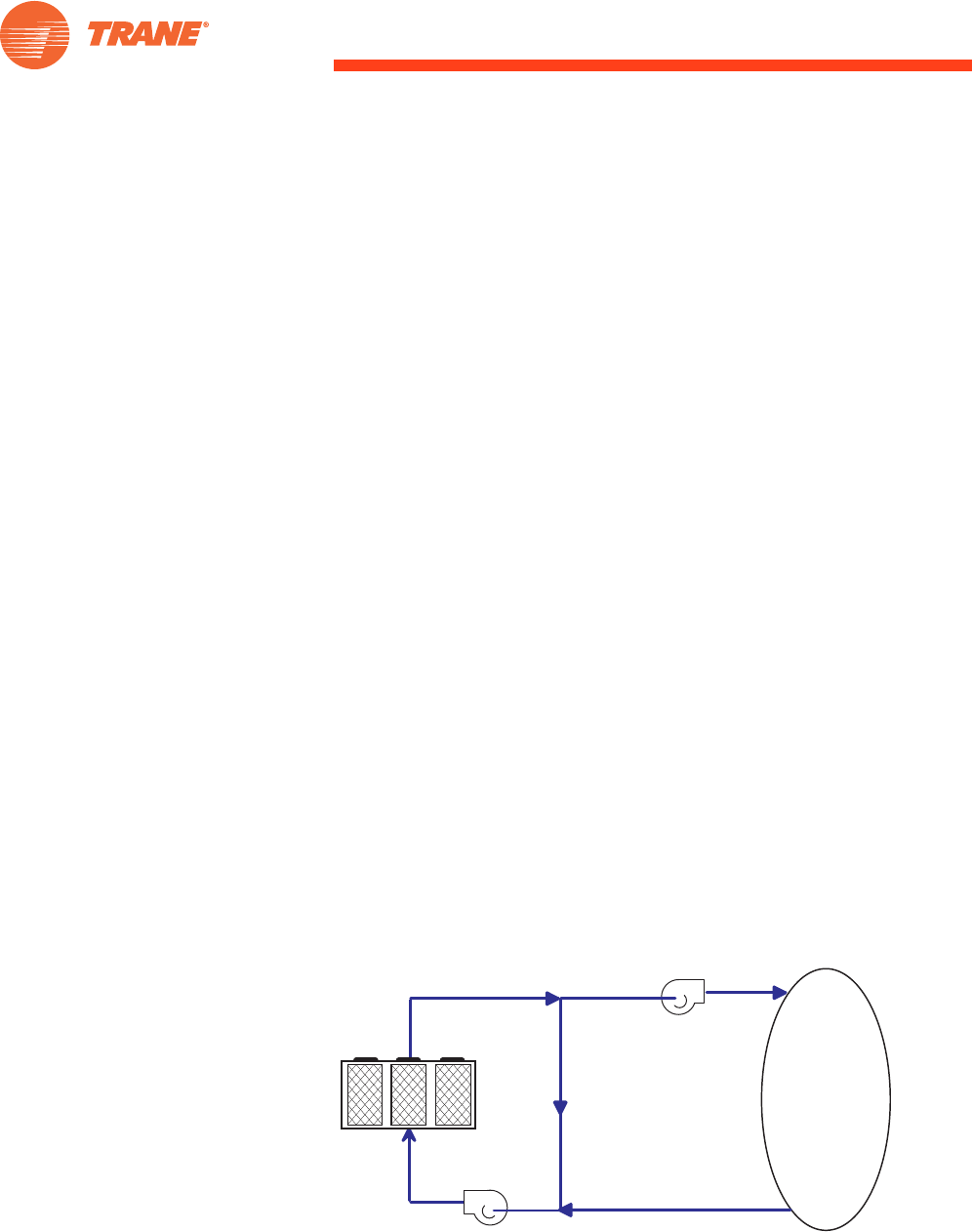

Flow rate out of range

A plastic injection molding process requires 80 gpm [5.1 L/s] of 50°F [10°C]

water and returns that water at 60°F [15.6°C]. The selected chiller can operate

at these temperatures, but has a minimum flow rate of 120 gpm [7.6 L/s]. The

following system in Figure 51 can satisfy the process. Decoupling the chiller

from the process load allows the water flow to be different, ensuring that the

flow through the chiller is within acceptable limits. With a single chiller

system, one pump and a three-way valve gives the same results.

Figure 51. Flow rate out of range for equipment

Process

Load

50°F [10°C]

80 gpm [5.1 L/s]

Constant Volume Pump

50°F [10°C]

40 gpm [2.3 L/s]

60°F [15.6°C]

80 gpm [5.1 L/s]

Constant Volume Pump

120 gpm [7.6 L/s]

56.7°F [13.7°C]

120 gpm [7.6 L/s]

50°F [10°C]

120 gpm [7.6 L/s]

Bypass

Pipe

Chiller