12 Chiller System Design and Control SYS-APM001-EN

Primary System Components

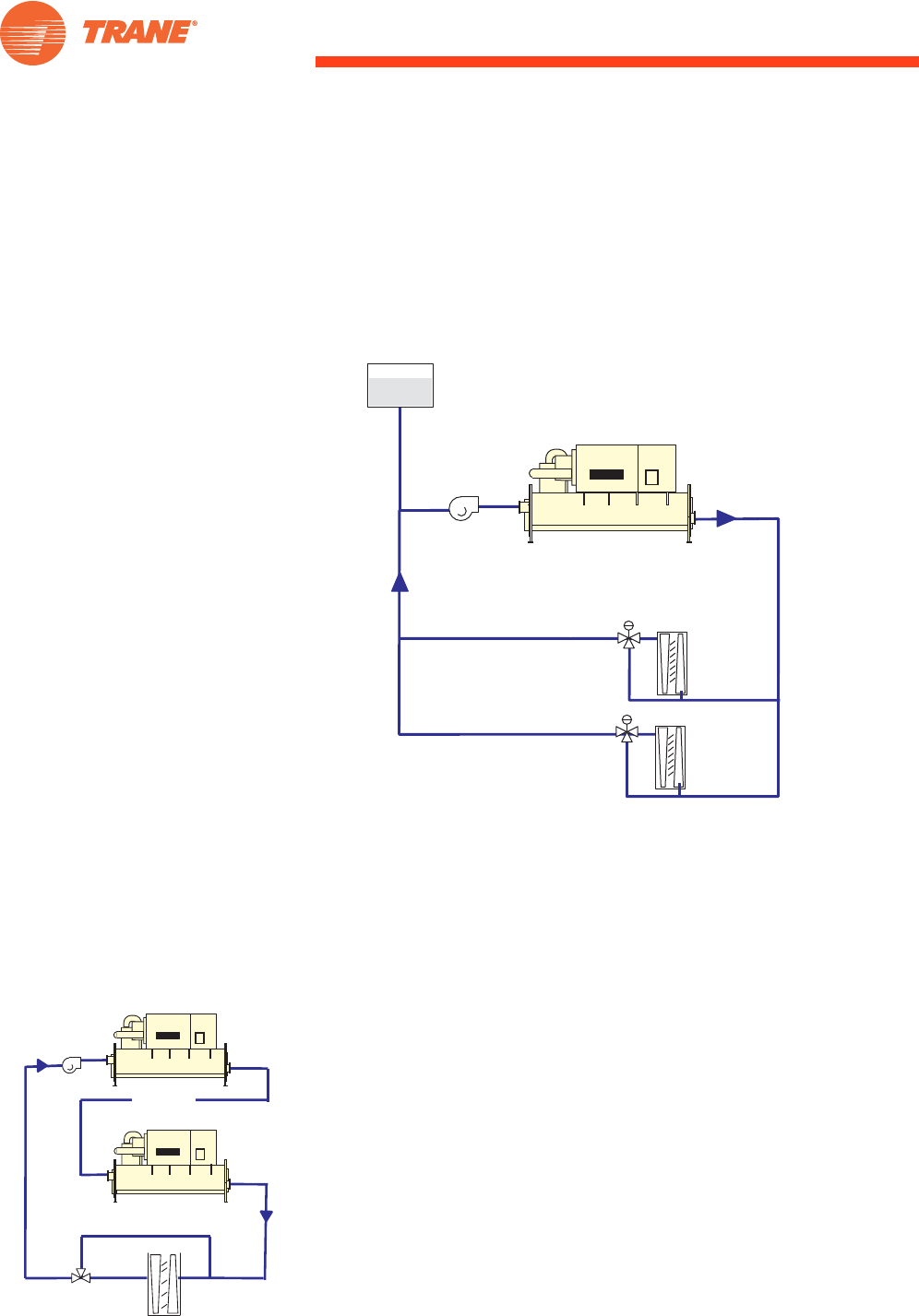

valves may be either three-way or two-way. As previously discussed, three-

way valves require constant water flow, while two-way valves allow the water

flow in the system to vary. As flow varies, the pump may simply ride its curve

or use a method of flow control such as a variable-speed drive. Refer to the

chapter “System Configurations” on page 42 for a detailed discussion of

distribution-system options.

Figure 11. Simplified distribution system

The distribution system may contain other components, such as an

expansion tank, control valves, balancing valves, check valves, and an air

separator, to name a few. The density, and therefore the volume, of the water

in a “closed” chilled-water distribution system varies as it undergoes

changes in temperature. The expansion tank allows for this expansion and

contraction of water volume.

Pumping arrangements

Variations on three basic pumping arrangements are common. They are

referred to as constant flow, primary-secondary (decoupled) flow, and

variable-primary flow (VPF). The implications and nuances of each of these is

discussed in greater detail in “System Configurations” on page 42.

Constant flow system

When a chiller is on, a constant speed pump dedicated to it is on, and there

need not be any other pumps operated in the system (Figure 12). This is a

simple system and makes the most sense when there will only be one chiller

operated at a time in the system. Challenges with this system arise at part

load when chillers are in the parallel arrangement (refer to “Parallel Chillers”

on page 42). To solve some of these problems, the chillers can be placed in

Expansion

Tank

Pump

Chiller

Distribution

Piping

Loads

Figure 12. Constant flow system

Load

Chillers

CV

Pump

Three-Way

Control

Valve