System Design Options

SYS-APM001-EN Chiller System Design and Control 39

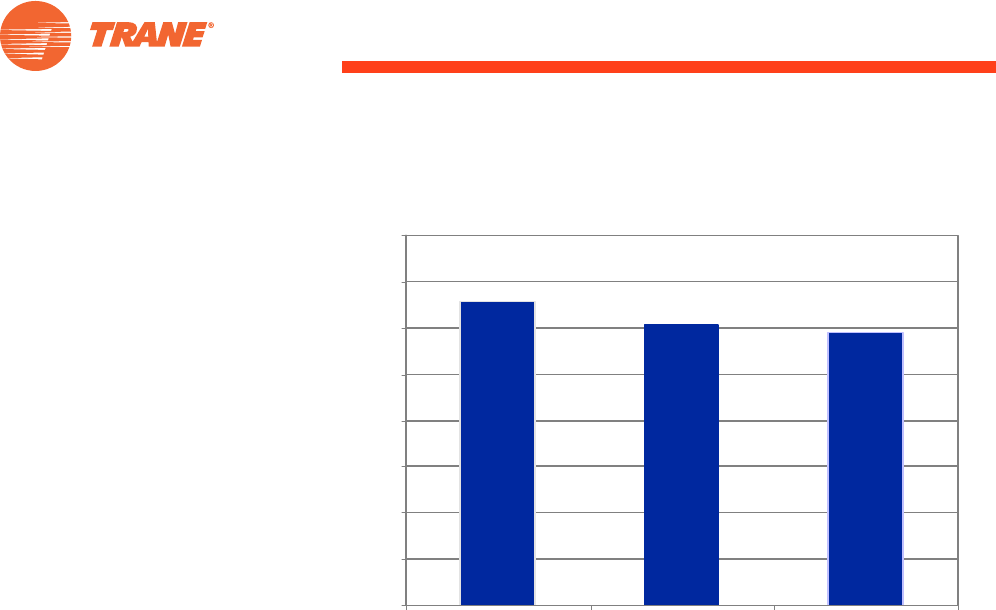

Figure 23. Annual system operating costs (absorption chillers)

Kelly and Chan

10

compare the operational costs of chilled-water system

designs in site locations. Their summary states:

In conclusion, there are times you can ’have your cake and eat it too.’

In most cases, larger Ts and the associated lower flow rates will not

only save installation cost but will usually save energy over the

course of the year. This is especially true if a portion of the first cost

savings is reinvested in more efficient chillers. With the same cost

chillers, at worst, the annual operating cost with the lower flows will

be about equal to “standard” flows but still at a lower first cost.

Misconceptions about Low-Flow Rates

Some common misconceptions about low-flow systems include:

1 Low flow is only good for long piping runs

2 Low flow only works well for specific manufacturers’ chillers

3 Low flow can only be applied to new chilled-water systems

Let’s discuss each of these three misconceptions.

Misconception 1—Low flow is only good for long piping

runs.

One way to examine this claim is to use our previous example, but to

concentrate on the condenser-water side. We’ll start with the example

covered on pages 30-32. Using the same chiller, but a smaller cooling tower

$-

$5,000

$10,000

$15,000

$20,000

$25,000

$30,000

$35,000

$40,000

4.45 gpm/ton 3.60 gpm/ton 3.09 gpm/ton

Condenser Water Flow