System Controls

SYS-APM001-EN Chiller System Design and Control 91

prevalent than either two-speed fans or pony motors. Using variable-speed

drives on cooling-tower fans offers two distinct benefits. First, the tower-

water-temperature control is extremely good. Second, the fan power varies

with the cube of the speed, so there is great potential for energy savings.

Variable-speed drives also allow the fan speed to be changed without fear of

gear box or motor wear. They may also offer acoustical advantages by

significantly lowering sound power at reduced speeds. Variable-speed drives

are also applicable to existing chilled-water systems.

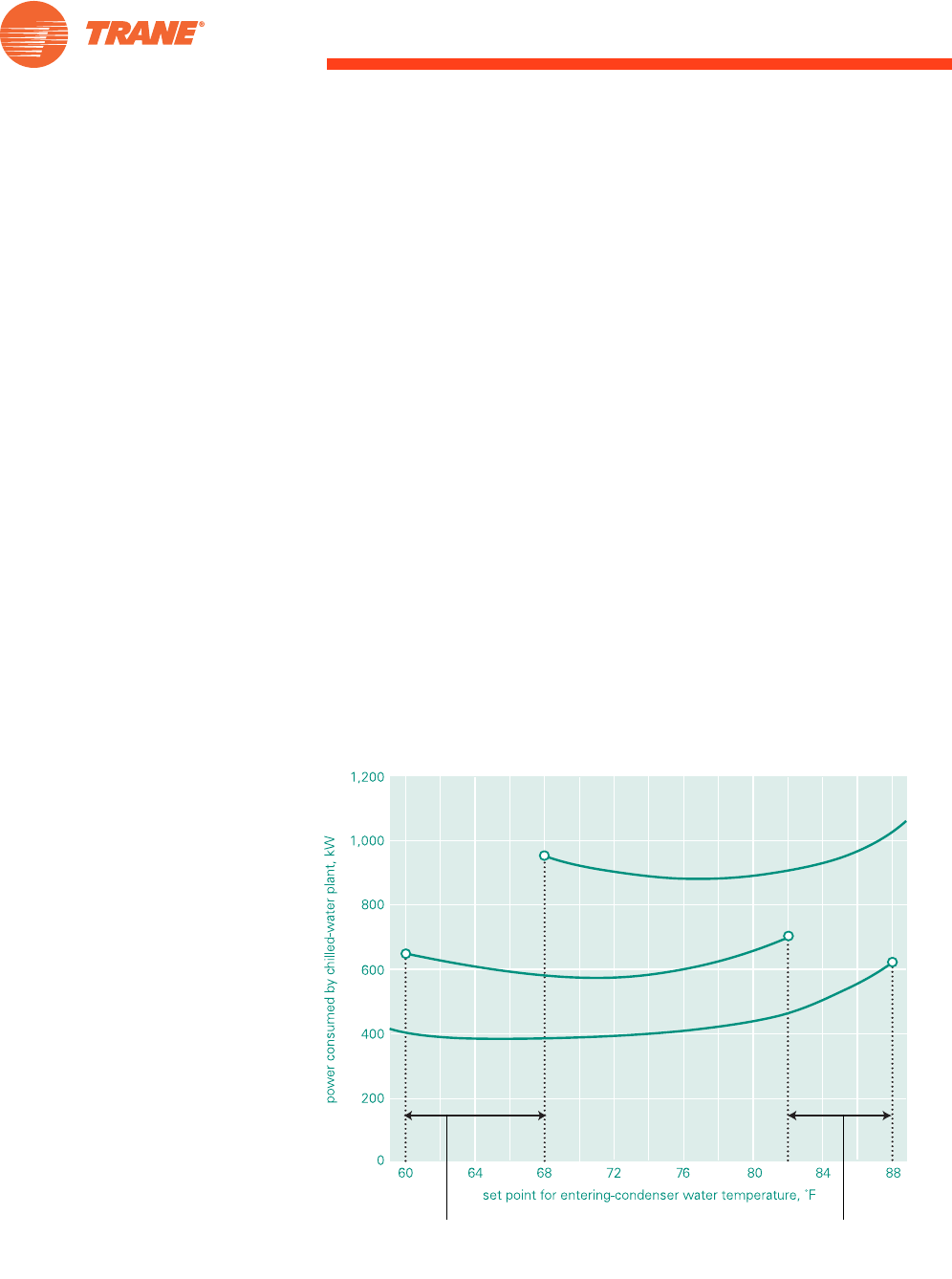

Chiller–tower energy balance

The subject of condenser-water temperature control has been studied by a

number of people. In recent years, Braun and Didderich

38

; Hydeman,

Gillespie, and Kammerud

39

; and Schwedler

40

have all independently noted

that balancing chiller and cooling-tower energy is important. Hydeman, et al.,

showed that at various loads and ambient conditions, the optimal condenser-

water temperature for a specific chilled-water system depends on both chiller

load and ambient conditions (see Figure 54). All the studies showed that

during many points of operation, the optimal condition is not the lowest

water temperature the cooling tower can produce. It is important for the

system designer and operator to examine the use of system-level controls to

set the tower-sump temperature setpoint to reduce the sum of chiller-plus-

tower energy. This optimal chiller-tower control can be automated by a

chiller-plant management system.

Figure 54. Chiller-tower energy consumption

Figure 54 from Hydeman, et al., used with permission.

Coldest condenser water that the

tower can produce at this load and

wet-bulb temperature

Highest cooling capacity

available at this condenser-

water temperature

1,650 tons [5,803 kw]

65°F [18.3°C] wet bulb

1,160 tons [4,080 kw]

59°F [15°C] wet bulb

730 tons [2,567 kw]

54°F [12.2°C] wet bulb