74 Chiller System Design and Control SYS-APM001-EN

Chilled-Water System Variations

One caveat when applying this arrangement is that chillers on the production

side of the bypass line will run more often at low part-load conditions. Older

chillers or newer chillers with a high cycle point may not have this capability.

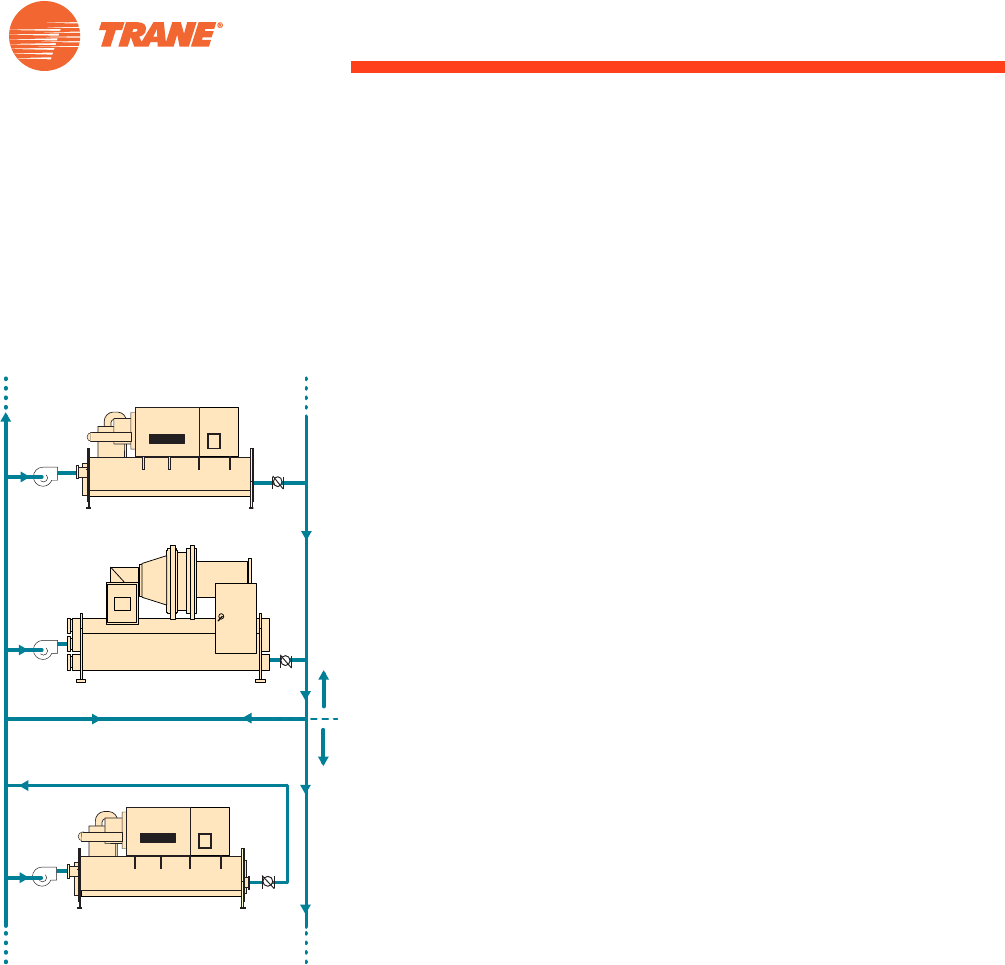

Preferential loading - sidestream arrangement

Figure 45 shows a simple modification to the traditional decoupled

arrangement. The sidestream arrangement ensures that the chiller piped in

the sidestream position still receives the warmest entering-water

temperature and can fully load it whenever the chiller plant operates.

This arrangement is unique because it not only allows preferential loading,

but it also permits the cooling device (chiller, heat exchanger, etc.) in the

sidestream position to operate at any leaving-water temperature. This

configuration precools the system-return water for the chillers downstream,

reduces their loads and energy consumption, and decreases the overall

operating cost of the chilled-water system.

When cooling devices are located in the return piping of the distribution loop,

they do not contribute to system demands for flow. They simply reduce the

temperature of return water to the production loop. While this is

counterproductive to the principle of striving for the highest possible return

water temperature, it is often the best way to obtain free cooling, specialized

heat recovery, or reduce the capital cost of ice storage equipment.

Sidestream, decoupled applications are usually most economical when the

sidestream chiller is smaller than those on the production side of the bypass

line. Since pumping requirements and energy consumption change with

modifications to the system arrangement, it is best to use a computerized

analysis tool to model the economic effects.

The following are different system configurations that can benefit from the

sidestream application.

Sidestream plate-and-frame heat exchanger

A free-cooling heat exchanger may be capable of chilling water to only 48°F

[8.9°C] during some periods. Rather than overlook this portion of cooling

capacity assistance, the heat exchanger does whatever it can to its portion of

the total return stream. Figure 40 on page 70 shows a possible chilled- and

condenser-water piping arrangement that allows for simultaneous waterside

economizer and chiller operation. Chillers operating downstream can reduce

chilled-water temperature further, allowing simultaneous free cooling and

mechanical cooling. This configuration increases the hours that the heat

exchanger may be used. Since this capacity is brought to bear on the

warmest water in the system, it allows the highest heat exchanger

effectiveness and has the greatest impact.

Chiller 3

Production

Distribution

Chiller 2

Bypass Line

Chiller 1

Figure 45. Sidestream preferential

loading arrangement

Sidestream position receives the

warmest return water.