2-41

Making Measurements

Cleaning Connections for Accurate Measurements

• Is an instrument-grade connector with a precision core alignment re-

quired?

• Is repeatability tolerance for reflection and loss important? Do your

specifications take repeatability uncertainty into account?

• Will a connector degrade the return loss too much, or will a fusion

splice be required? For example, many DFB lasers cannot operate with

reflections from connectors. Often as much as 90 dB isolation is needed.

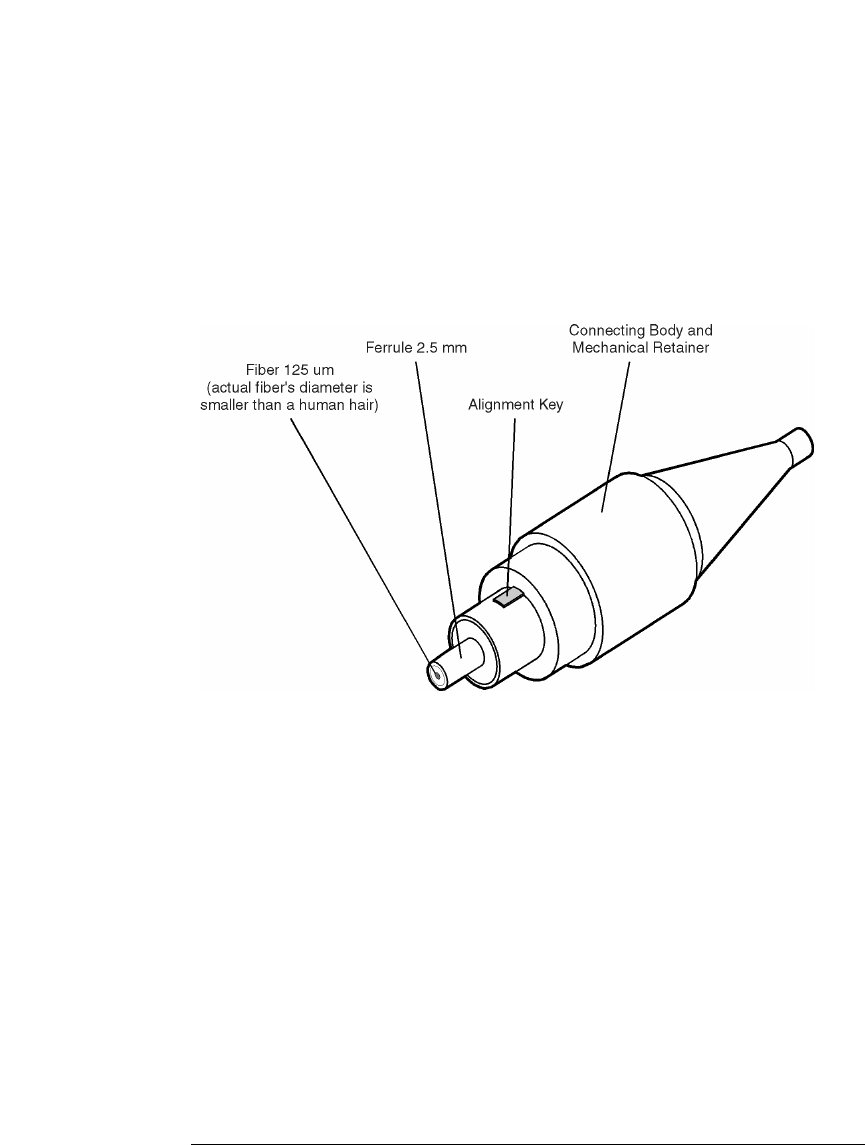

Figure 2-3. Basic components of a connector.

Over the last few years, the FC/PC style connector has emerged as the

most popular connector for fiber-optic applications. While not the

highest performing connector, it represents a good compromise

between performance, reliability, and cost. If properly maintained and

cleaned, this connector can withstand many repeated connections.

However, many instrument specifications require tighter tolerances

than most connectors, including the FC/PC style, can deliver. These

instruments cannot tolerate connectors with the large non-concentrici-

ties of the fiber common with ceramic style ferrules. When tighter

alignment is required, Agilent Technologies instruments typically use a

connector such as the Diamond HMS-10, which has concentric toler-

ances within a few tenths of a micron. Agilent Technologies then uses

a special universal adapter, which allows other cable types to mate

with this precision connector. See Figure 2-4.