2-45

Making Measurements

Cleaning Connections for Accurate Measurements

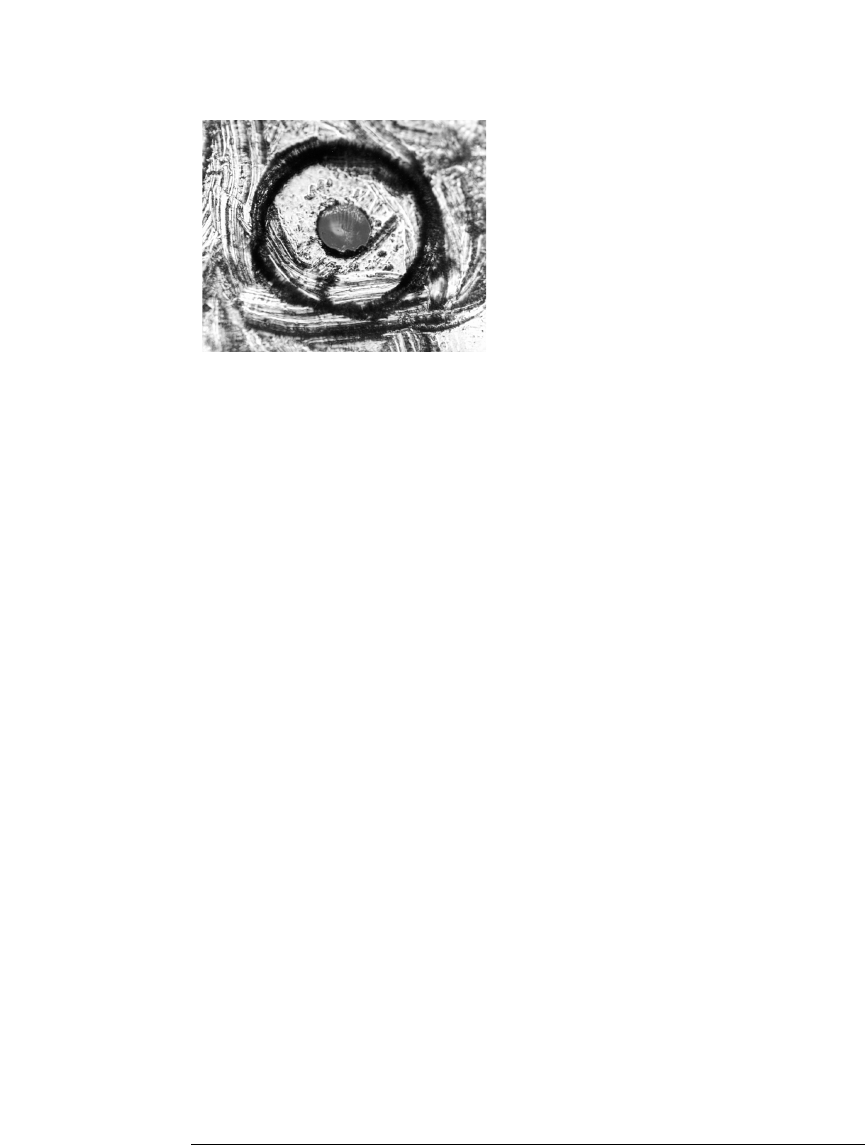

Figure 2-8. Damage from improper cleaning.

While these often work well on first insertion, they are great dirt mag-

nets. The oil or gel grabs and holds grit that is then ground into the

end of the fiber. Also, some early gels were designed for use with the

FC, non-contacting connectors, using small glass spheres. When used

with contacting connectors, these glass balls can scratch and pit the

fiber. If an index matching gel or oil must be used, apply it to a

freshly cleaned connector, make the measurement, and then immedi-

ately clean it off. Never use a gel for longer-term connections and

never use it to improve a damaged connector. The gel can mask the

extent of damage and continued use of a damaged fiber can transfer

damage to the instrument.

• When inserting a fiber-optic cable into a connector, gently insert it in

as straight a line as possible. Tipping and inserting at an angle can

scrape material off the inside of the connector or even break the inside

sleeve of connectors made with ceramic material.

• When inserting a fiber-optic connector into a connector, make sure that

the fiber end does not touch the outside of the mating connector or

adapter.

• Avoid over tightening connections.

Unlike common electrical connections, tighter is not better. The pur-

pose of the connector is to bring two fiber ends together. Once they

touch, tightening only causes a greater force to be applied to the deli-

cate fibers. With connectors that have a convex fiber end, the end can

be pushed off-axis resulting in misalignment and excessive return loss.

Many measurements are actually improved by backing off the connec-