111

Parameter list

Parameter list

5

ADJUSTMENT

Motor noise suppression and measures against EMC and leakage current — Reducing

mechanic resonance

(speed smoothing control) (Pr.653, Pr.654)

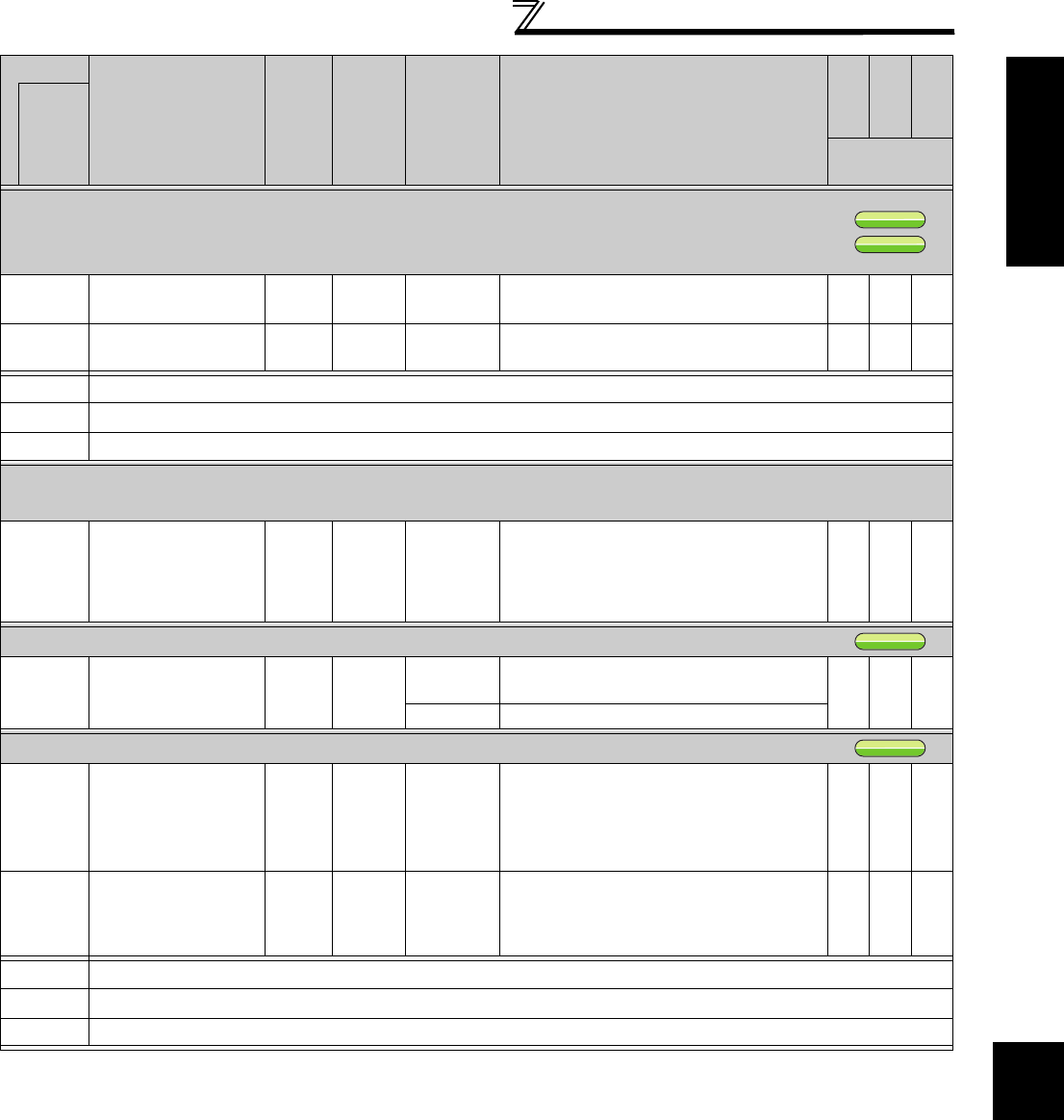

653

Speed smoothing

control

0.1% 0

0 to 200%

The torque fluctuation is reduced to reduce

vibration due to mechanical resonance.

654

Speed smoothing

cutoff frequency

0.01Hz 20Hz

0 to 120Hz

Set the minimum value for the torque

variation cycle (frequency).

665

Refer to Pr.52.

779

Refer to Pr.331.

791, 792

Refer to Pr.7 and Pr.8.

Function assignment of external terminal and control — Pulse train output of output

power (Y79 signal) (Pr.799)

799

Pulse increment

setting for output

power

0.1kWh 1kWh

0.1kWh,

1kWh,

10kWh,

100kWh,

1000kWh

Pulse train output of output power (Y79) is

output in pulses at every output current

(kWh) that is specified.

IPM motor control — Control method selection (Pr.800)

800

Control method

selection

120

9

IPM motor test operation (Motor is not

driven even if it is connected.)

20

Normal operation (Motor can be driven.)

IPM motor control — Proportional gain setting for speed loops (Pr.820, Pr.821)

820

Speed control P gain

1

1% 25% 0 to 1000%

The proportional gain during speed control

is set. (Setting this parameter higher

improves the trackability for speed

command changes. It also reduces the

speed fluctuation due to a load fluctuation.)

821

Speed control integral

time 1

0.001s 0.333s 0 to 20s

The integral time during speed control is set.

(Setting this parameter lower shortens the

return time to the original speed when the

speed fluctuates due to external forces. )

867

Refer to Pr.54 to Pr.56.

870

Refer to Pr.43.

872

Refer to Pr.251.

Parameter

Name

Incre-

ments

Initial

Value

Range Description

Parameter

copy

Parameter

clear

All parameter

clear

Related

parameters

: enabled

× : disabled

V/F

V/F

V/F

S

MFVC

S

MFVC

S

MFVC

IPM

IPM

IPM

IPM

IPM

IPM