57

Model PH90 Operating Procedures

081210

Step 3

Open the draw valve on the freezer door. Drain all the

rinse water from the door spout, close the draw valve,

and press the WASH keypad, cancelling t he wash

cycle.

Step 4

Repeat this procedure using clean, warm water, until

the water being discharged is clear.

Repeat steps 1 through 4 for the soft serve side of

the freezer.

Cleaning and Sanitizing

To clean and sanitize both sides of the freezer , the

steps will be the same. Therefore, first clean and

sanitize the shake side, then go back and duplicate

these p rocedures for the soft serve side.

Step 1

Prepare a pail of an approved 100 PPM cleaning solu-

tion (examples: 2--1/2 gal. [9.5 liters] of Kay--5R or

2 gal. [7.6 liters] of Stera--SheenR). USE WARM WA-

TER AND FOLLOW THE MANUF ACTURER’S

SPECIFICATIONS.

Step 2

Pour the cleaning solution into the hopper and allow it

to flow into the freezing cylinder.

Step 3

While the solution is flowing into the freezing cylinder ,

brush clean the mix hopper, mix level sensing probes,

the outside of the agitator drive shaft housing, and the

mix inlet hole.

Step 4

Press the WASH keypad. This will cause the cleaning

solution in the freezing cylinder to be agitated.

Step 5

Place an empty pail beneath the door spout.

Step 6

Open the draw valve on the freezer door and draw off

all the solution.

Step 7

Once the cleaner stops flowing from the door spout,

close the draw valve and press the WASH keypad,

cancelling the wash cycle.

Step 8

Prepare a pail of an approved 100 PPM sanitizing

solution (examples: 2--1/2 gal. [9.5 liters] of Kay--5 R

or 2 gal. [7.6 liters] of Stera--S heenR). USE WARM

W ATER AND FOLLOW THE MANUFACTURER’S

SPECIFICATIONS.

Repeat steps 2 through 7 with the sanitizing

solution.

Repeat steps 1 through 8 for the soft serve side of

the freezer.

Disassembly -- Shake Side

Note: Failure to remove parts, brush clean and

re--lubricate these parts, will result in damage to the

related parts. These parts must be removed every 14

days or the machine will lock out and not operate in the

AUTO mode.

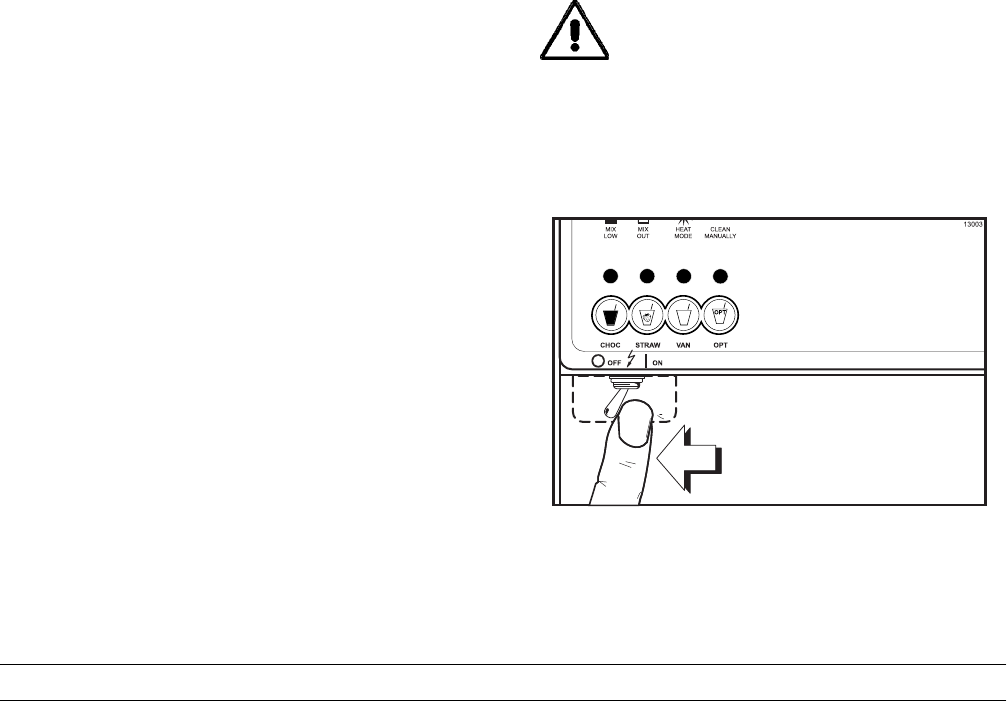

MAKE SURE POWER SWITCH IS IN THE

“OFF ” POSITION. Failure to do so may cause injury

from hazardous moving parts, or electrocution. (See

Figure 125.)

Figure 125