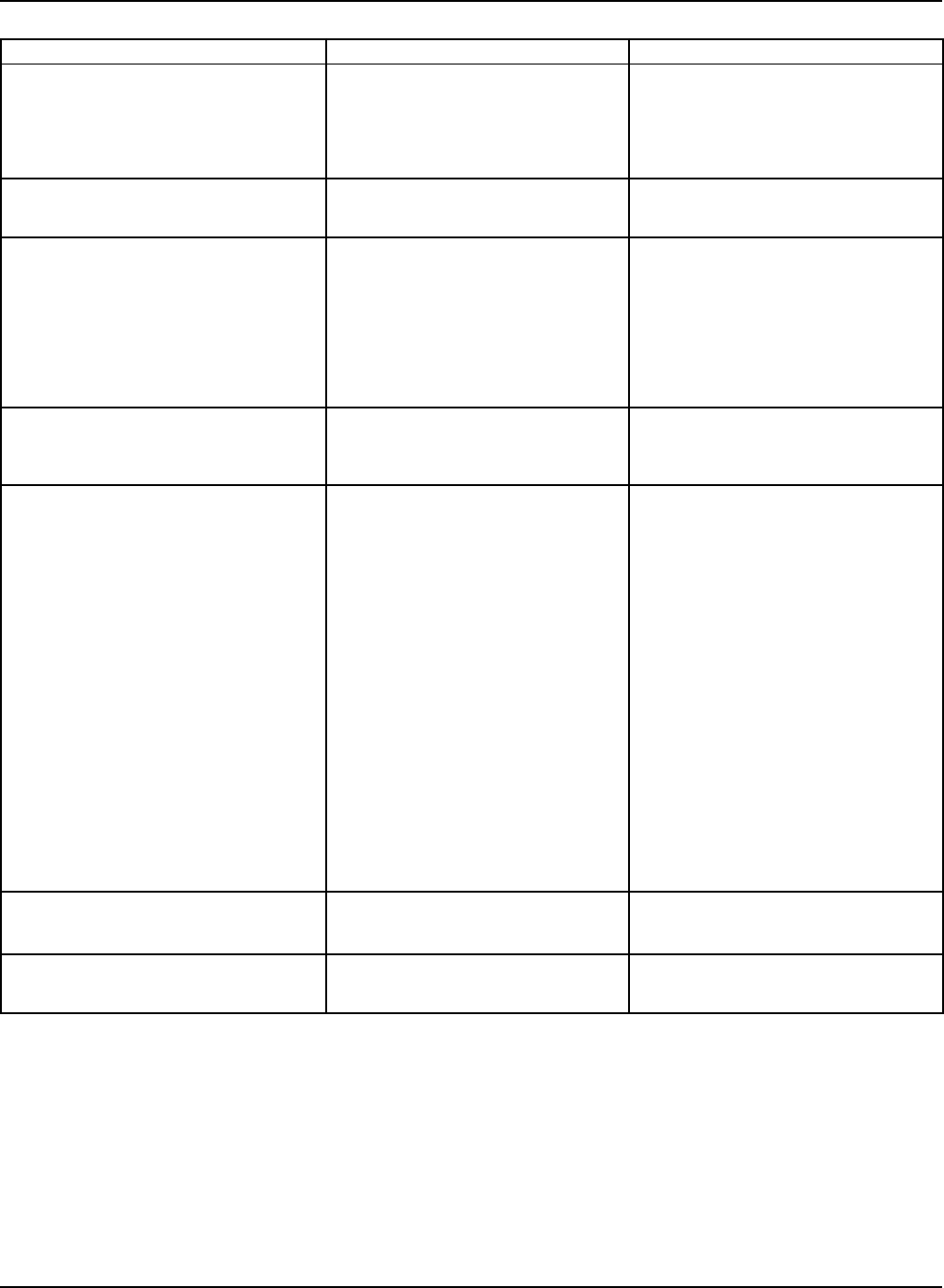

Problem Cause Correction

Box rear flap pulled back out of box. Rear flap folder out of adjustment. Adjust Rear Flap Folder (refer to

Section 3).

Flaps not positioned properly

before entering case sealer. Position flaps properly.

Front of box crushed by upper Paddle is not returning after Adjust Paddle Pressure Regulator

head assembly. previous box. (refer to Section 3).

Crease marks on upper surface of Upper head assembly is coming Adjust Case Top Sensitivity

box. down too far. (refer to Section 3).

AdjustCounter-Balance Pressure

Regulator (refer to Section 3).

Adjust Upper Head Assembly

Down/Up Rates (refer to Section 3).

Box drives to fork, belts stop, head PC 6 blocked. Remove blockage.

doesnt come down, and no further

machine operation.

Tape leg on front of case is too long. Tape is threaded incorrectly. Tape must go around tension wrap

roller before going around one-way

tension roller.

Tape tension is too low. Adjust One-Way Tension Roller

(refer to Section 3).

Knurled roller drags. Check for adhesive build-up

between the knurled roller and its shaft. If problem continues, replace

with new flanged roller

78-8070-1367-3.

Tape tracks to one side or drags on Adjust Tape Web Alignment

support tabs of the applying frame. (refer to Section 3).

One-way roller is not positioned Position roller in its mounting slot

properly. so that tape extends beyond the

centerline of applying roller.

Head is not set up properly. Check leg length adjustments.

Blade does not cut tape or tape end Blade is dull and/or has broken Replace blade.

is jagged or shredded. teeth.

(continued) Tape tension is not sufficient. Adjust one-way roller to increase

tape tension.

Troubleshooting 3M-Matic 800rf Case Sealer

6-2 Copyright 1999, 3M IPC. All rights reserved.