Adjustments 3M-Matic 800rf Case Sealer

3-20 Copyright 1999, 3M IPC. All rights reserved.

3-25. Tape Drum Friction Brake

Specification

Adjust the tape drum friction brake to prevent exces-

sive tape overtravel caused by a flywheel effect.

Adjustment

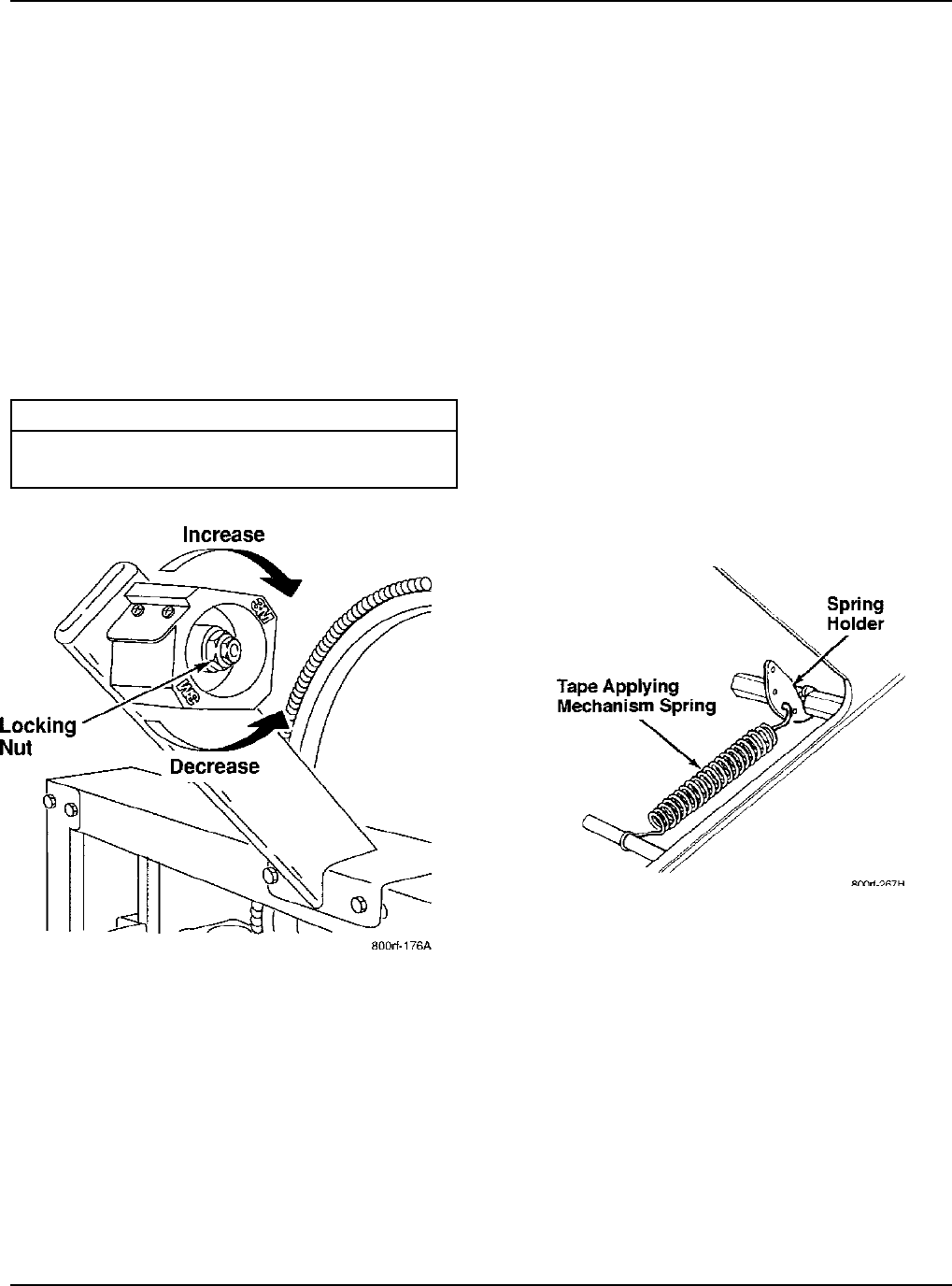

1. Refer to Figure 3-25. Turn the self-locking nut on

the shaft to adjust the braking force (CW

increases braking force, CCW decreases

braking force).

2. Adjust the friction brake for the minimum

braking force that prevents excessive overtravel.

ü Note

Excessive braking force causes poor tape application

and may lead to tape tabbing on the trailing tape leg.

Figure 3-25. Tape Drum Friction Brake

Adjustment

3-26. Tape Applying Mechanism Spring

Specification

Adjust the position of the tape applying mechanism

spring so there is sufficient pressure to seal the box,

and after sealing the box, the tape buffing roller

returns to its rest position.

Adjustment

1. To gain access to the spring, remove the taping

head cover (four mounting screws).

2. Increase or decrease the pressure applied by the

tape applying mechanism spring by removing the

end loop from the spring holder and moving it to

another hole. Refer to Figure 3-26.

3. If a tape gap appears on the trailing surface of the

box, increase the spring pressure.

4. If the front of the box is being crushed by the

applying roller, decrease the spring pressure.

Figure 3-26. Tape Applying Mechanism Spring

Adjustment

5. Replace the taping head cover (four mounting

screws).