3M-Matic 800rf Case Sealer Adjustments

Copyright 1999, 3M IPC. All rights reserved. 3-13

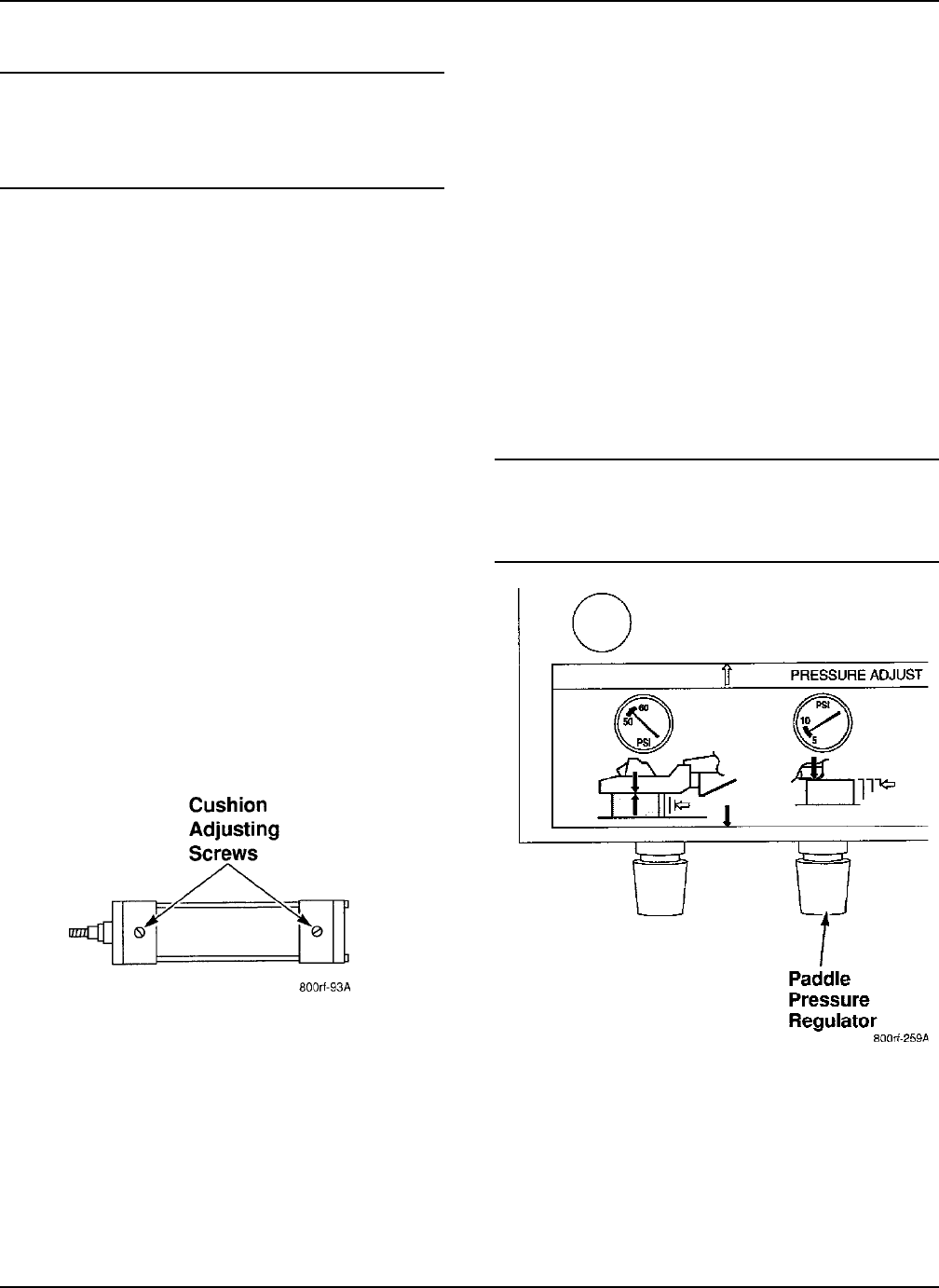

3-15. Cylinder Cushion Setting

ü Note

This is a generic approach to adjusting the cylinder

cushion settings for all cylinders used in the 800rf

Case Sealer.

This is not a routine adjustment. Normally, it is not

necessary to adjust the cylinder cushion settings

unless a new cylinder is installed to replace an

original component.

Specification

Adjust cushion settings so that the cylinder does not

bottom out hard at the end travel of its stroke.

Adjustment

Set the cylinder cushions for the setting that allows

proper operation as described in the above specifica-

tion. Typically, these are factory set and do not need

to be adjusted.

1. Refer to Figure 3-16 for adjusting screw loca-

tions. This is a generic view for all cylinders used

in the 800rf Case Sealer.

2. Turn the adjusting screws fully CW (closed).

3. Adjust by turning the screws 1/8 to 1/4 turn

CCW.

Figure 3-16. Cushion Adjusting Screw Locations

3-16. Paddle Pressure Regulator

Specification

The Paddle Pressure Regulator should be set so that

as the paddle makes contact with the top of the carton

when the upper head assembly descends, it does not

overtravel and deform the carton.

Adjustment

1. Refer to Figure 3-17. Adjust the Paddle Pressure

Regulator on the underside of the Pneumatic

Control Panel so the gauge reads 7 PSIG with

the Main Air Pressure Regulator set correctly

(CW increases pressure, CCW decreases

pressure). Observe the Paddle Pressure Gauge on

the top of the panel.

ü Note

Too much pressure results in excessive drag on the

top of the carton or deforming of the carton.

Figure 3-17. Paddle Pressure Regulator

Adjustment