3M-Matic 800rf Case Sealer Preventative Maintenance

Copyright 1999, 3M IPC. All rights reserved. 8-5

8-4-3. Main Assembly

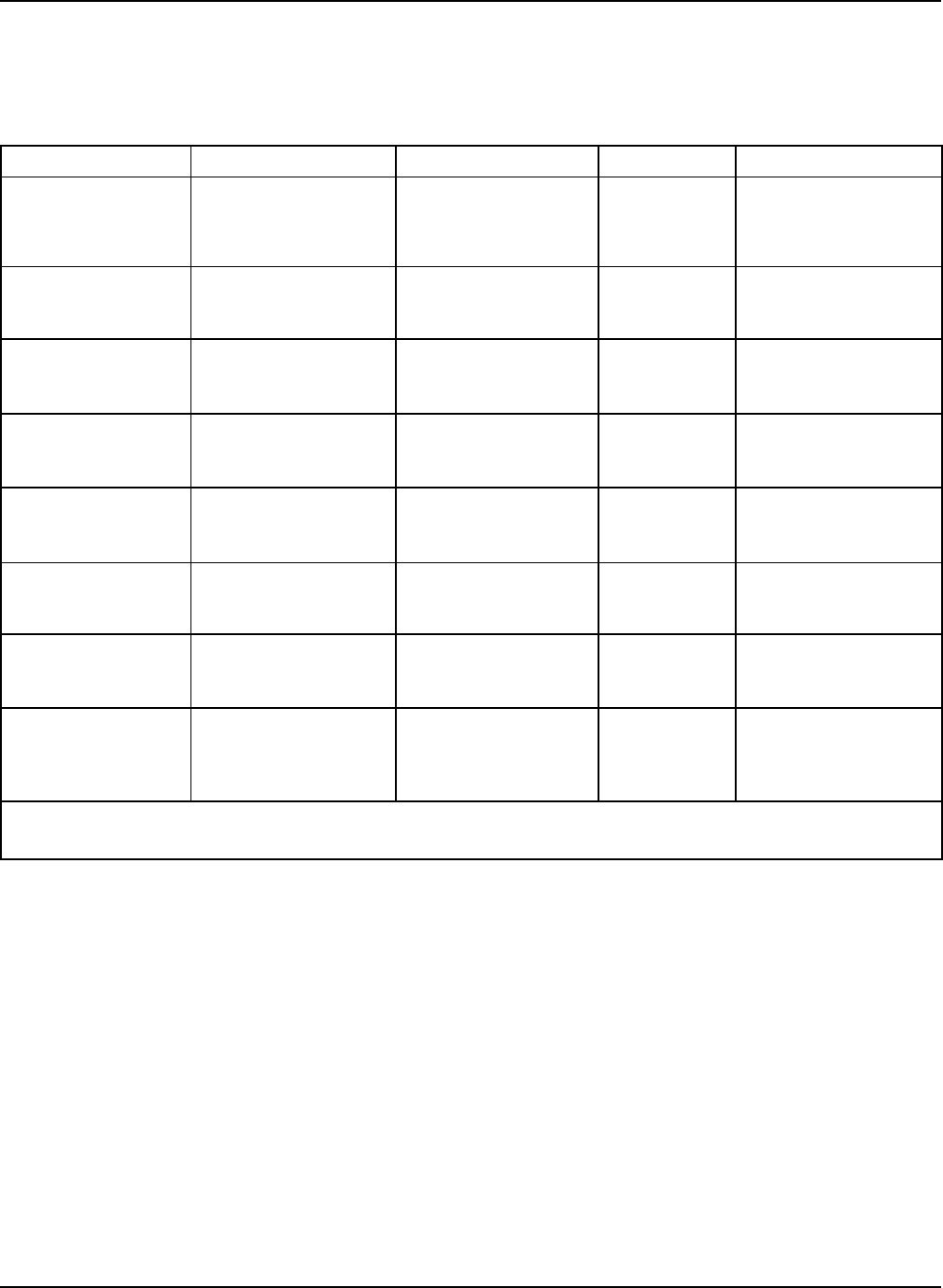

The following table provides recommendations for inspecting and replacing parts, and cleaning and lubricating

the main assembly.

Main Assembly Inspect/Replace Clean Lubricate Counter Cycles *

Side Drive Belts Inspect at 250 hours. 250 hours. N.A. Every 120,000 cycles.

Replace when worn, Vacuum.

or slipping on carton.

Belt Drive Rings Inspect at 500 hours. N.A. N.A. Every 240,000 cycles.

Replace when worn,

or wont drive belts.

Side Belt Closure Inspect at 250 hours. N.A. 250 hours. Every 120,000 cycles.

Assembly Chains, Replace as needed. Multipurpose

Shafts, and Bushings

grease.

Side Belt Drive Inspect at 250 hours. N.A. 250 hours. Every 120,000 cycles.

Assembly Chains Replace as needed. Multipurpose

grease.

Column Assembly Inspect at 250 hours. N.A. 250 hours. Every 120,000 cycles.

Column Guides Replace as needed. Multipurpose

grease.

Top Flap Inspect at 250 hours. N.A. 250 hours. Every 120,000 cycles.

Compression Replace as needed. 3M 5-Way

Roller Bushings Penetrant.

Side Drive Belt Inspect at 250 hours. N.A. 250 hours. Every 120,000 cycles.

Rails Multipurpose

grease.

Main Air Pressure Inspect as needed. Drain. Do not allow N.A. N.A.

Regulator/Filter Replace as needed. water to go above

filter element. Clean

as needed.

* Based on an average of 8 cartons/minute. (480 cartons/hour x 250 hours = 120,000 cycles)

(480 cartons/hour x 500 hours = 240,000 cycles)