3M-Matic 800rf Case Sealer Adjustments

Copyright 1999, 3M IPC. All rights reserved. 3-15

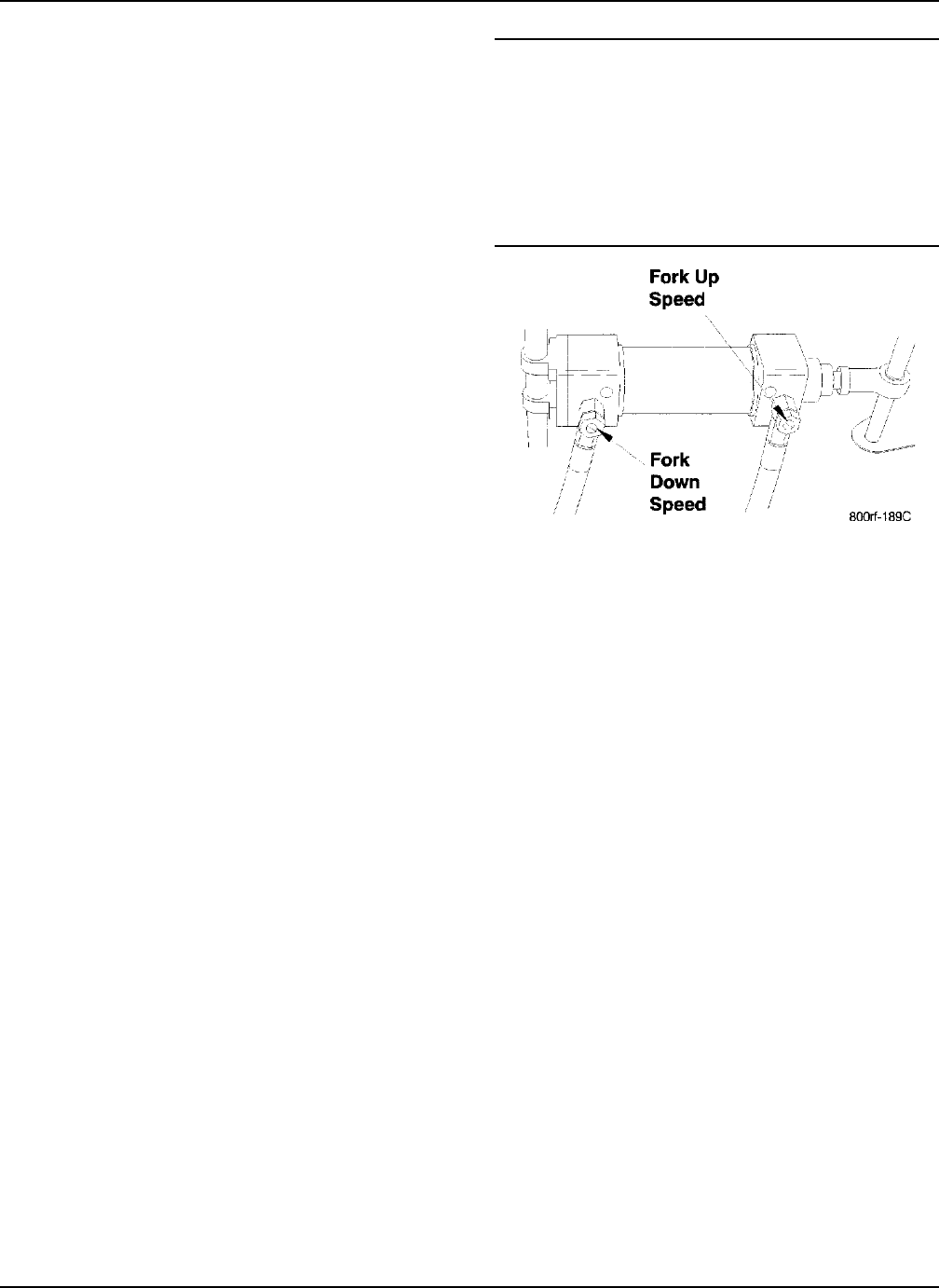

3-19. Fork Lift Flow Controls-Speed

Controls

These cylinder-mounted speed flow controls are

factory set and normally do not need adjusting unless

related components are replaced.

Specification

Adjust the Fork Cylinder speed flow controls so that:

1. The fork automatically moves down to its hori-

zontal position before case movement forces it

down.

2. The fork returns to its upright vertical position

before the side belts begin to move inward to

receive the next carton.

3. Fork movement occurs without banging or

rebound.

Adjustment

Before making any adjustments on these speed flow

controls, the Main Air Pressure Regulator must be set

correctly.

1. Remove the center conveyor bed as described in

Section 4-6, Case Sealer Bed Plates.

2. Refer to Figure 3-20. Adjust the Fork Cylinder

speed flow controls (CW decreases speed,

CCW increases speed).

a. Adjust the cap end to control the speed of the

retract (fork down) motion.

b. Adjust the rod end to control the speed of the

extend (fork up) motion.

3. Replace the center conveyor bed.

ü Note

If there is any confusion as to where to set the speed

flow controls, turn the adjusting screws fully CW,

then turn the cap-end screw 12 full turns CCW and

turn the rod-end screw 13 full turns CCW. Refer to

Table 3-1, Pneumatic Device Factory Set Points and

Adjustment Locations (Cylinder Mounted Speed

Controls).

Figure 3-20. Fork Speed Control Adjustment