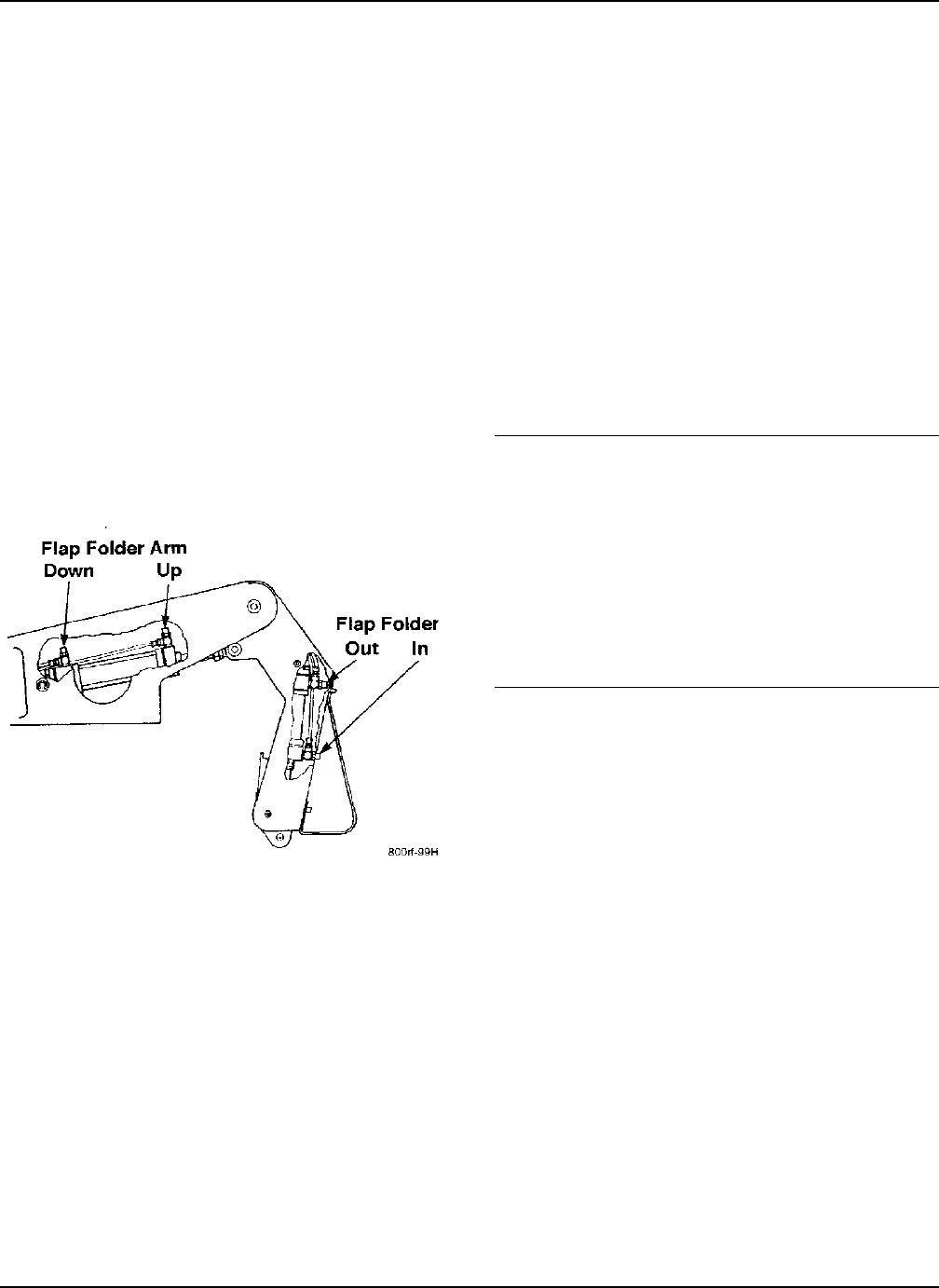

3-13. Flap Folder Arm and Flap Folder Flow

Controls - Speed Controls

This is not a routine adjustment. Normally, it is

necessary only after major disassembly or repair of

related components.

Specification

Adjust the cylinder-mounted speed flow controls

for optimum stroke operation. Consider a smooth

cylinder extension and retraction without banging at

the end of either motion.

Adjustment

The Flap Folder Arm Cylinder and the Flap Folder

Cylinder both have speed flow controls located at

each end of the cylinders; one control at the cap end,

and one control at the rod end. Refer to Figure 3-14.

Figure 3-14. Flap Folder Arm and Flap Folder

Speed Control Adjustments

3M-Matic 800rf Case Sealer Adjustments

Copyright 1999, 3M IPC. All rights reserved. 3-11

1. Adjust the Flap Folder Arm Cylinder speed

flow controls (CW decreases speed,

CCW increases speed).

a. Adjust the cap end to control the speed of the

retract (down) motion.

b. Adjust the rod end to control the speed of the

extend (up) motion.

2. Adjust the Flap Folder Cylinder speed

flow controls (CW decreases speed,

CCW increases speed).

a. Adjust the cap end to control the speed of the

retract (out to fold flap) motion.

b. Adjust the rod end to control the speed of the

extend (in to home position) motion.

ü Note

If there is any confusion as to where to set the speed

flow controls, turn the adjusting screws fully CW.

Flap Folder Arm Cylinder turn the cap-end screw 5

full turns CCW and turn the rod-end screw 11 full

turns CCW. Flap Folder Cylinder turn the cap-end

screw 10 full turns CCW and turn the rod-end screw

16 full turns CCW. Refer to Table 3-1, Pneumatic

Device Factory Set Points and Adjustment Locations

(Cylinder Mounted Speed Controls).