3M-Matic 800rf Case Sealer Adjustments

Copyright 1999, 3M IPC. All rights reserved. 3-17

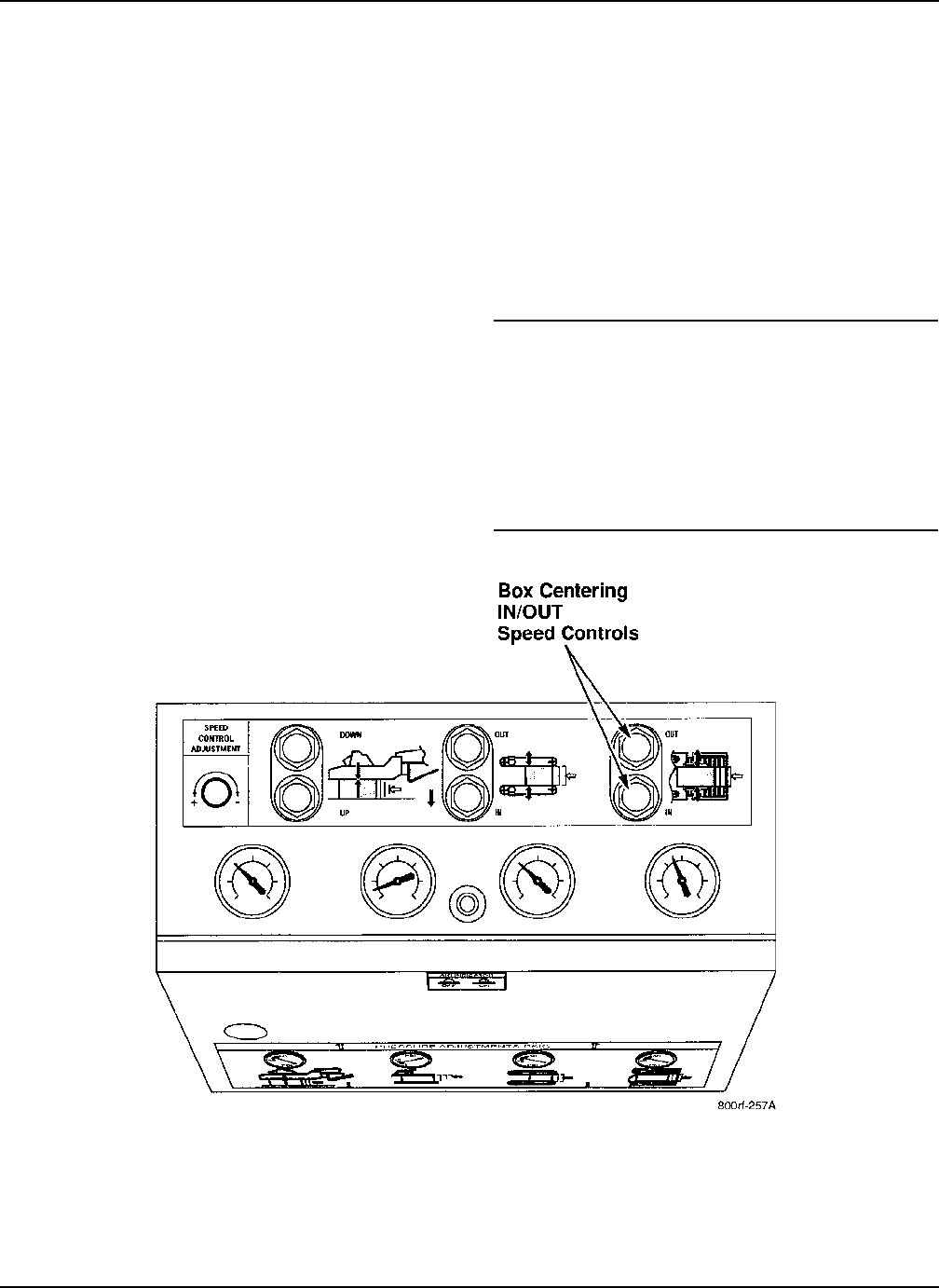

3-21. Box Centering Rails In/Out Rates

This is not a routine adjustment. Normally, it is

necessary only after major disassembly or repair of

related components.

Specification

Adjust the Box Centering IN/OUT speed flow

controls to allow the centering rails to close (move

IN) and center the carton, then release (move OUT)

and open to their home position at approximately the

same speed. The rate of closure (IN) is the primary

measure of a good speed. It must be slow enough to

center but not bounce a small box, and not so slow as

to reduce the overall production rate.

Adjustment

1. Pass some average size boxes through the case

sealer.

2. Observe the speed of the centering rails closure

(IN) and return (OUT).

3. Adjust the Box Centering IN/OUT speed control

valves, as shown in Figure 3-21 (CW decreases

speed, CCW increases speed). These controls

are located on the top of the Pneumatic Control

Panel, extreme right.

ü Note

If there is any confusion as to where to set the speed

control valves, turn the valves fully CW and then

turn the OUT control 6 full turns CCW and turn the

IN control 11 full turns CCW. Refer to Table 3-1,

Pneumatic Device Factory Set Points and Adjust-

ment Locations (Pneumatic Control Panel Mounted

Speed Controls).

Figure 3-21. Box Centering Rails IN/OUT Rate Adjustment