3M-Matic 800rf Case Sealer Theory of Operation

Copyright 1999, 3M IPC. All rights reserved. 5-1

5. Theory of Operation

5-1. General

This section begins with an operation summary,

which gives an overview of the operations that the

Model 800rf Type 39800 Case Sealer performs as it

seals a carton. Next, the sequence tables provide a

detailed sequence of actions the case sealer performs

while operating in Random mode, Fixed mode, or

Bypass mode. Then, the electrical system is de-

scribed, including special circuits and components.

The section ends with a description of the pneumatic

system.

5-2. Operation Summary

The 800rf case sealer runs in three separate modes of

operation: Random, Fixed, and Bypass. These

operating modes are described in the following

subsections.

5-2-1. Random Mode

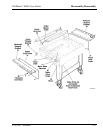

When a box enters and passes through the case sealer,

it passes six photocells in sequence. As the box clears

the light path of the first photocell, the infeed gate

moves up to prevent the entry of the next box. A pair

of centering rails then move inward to center the box

on the infeed rollers.

Infeed drive rollers move the box past a second

photocell which senses the presence of the box to

subsequently control the timing of the side belt

restart circuit.

The box continues to move, blocking the light path of

the third photocell. This causes the side belt drive

assemblies to move inward and press against the sides

of the box. The counter adds 1 to the cycle count, and

the box is carried forward, blocking the light path of

the fourth photocell. The side belt drive motors turn

off, and the box stops at the fork beneath the head

assembly.

When the box blocks the light path of the fourth

photocell, the side belt drive assemblies lock in

position, the upper head assembly brakes unlock, and

the head assembly begins to move downward. This

downward movement continues until a paddle presses

against the front flap of the box, folding the flap

inward. Downward movement of the head assembly

continues until resistance of the box leading edge

moves the paddle upward, actuating the box height

limit switch. An output from the controller stops

downward movement of the head assembly. At this

time, the head assembly and paddle lock in position,

the fork moves down, and the rear flap-folding

process occurs.

Rear flap folding begins with the action of the flap

folder arm. As this arm moves downward, an associ-

ated limit switch actuates an output from the control-

ler which causes the rear flap folder to move down,

folding the rear flap of the box inward.

The timing for the side belt drive motors to start

depends on whether the box is short or long. For a

short box (second photocell not blocked), the drive

motors are delayed momentarily to allow the rear flap

to be folded and then the motors turn on. For a long

box (second photocell blocked), the side belt drive

motors turn on first and then the rear flap is folded

when the box clears the second photocell.

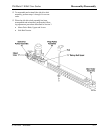

The side belt drive assemblies move the box toward

the taping heads. As the box moves forward, the side

flaps are folded inward and then held in position by

compression rollers. The box passes between the

taping heads and a C-clip of tape is applied to the top

and bottom center seams of the box.

As the box exits the case sealer, it clears the light

path of the fifth photocell and the controller homes

the case sealer, preparing it for the next box. At this

time, the flap folder arm and rear flap folder move up,

the side belt drive assemblies move out, the paddle

moves down, and the upper head assembly raises and

locks in the up position.