10

There is a display on the front of the Benshaw, Inc., solid-

state starters that is useful for troubleshooting and starter

checkout. The display indicates:

• voltage to the SCRs

• SCR control voltage

• power indication

• proper phasing for rotation

• start circuit energized

• over-temperature

• ground fault

• current unbalance

• run state

• software configuration

The starter is further explained in the Check Starter and

Troubleshooting Guide sections, pages 54 and 76.

Unit-Mounted Wye-Delta Starter (Optional) —

The 19XR chiller may be equipped with a wye-delta starter

mounted on the unit. This starter is used with low-voltage mo-

tors (under 600 v). It reduces the starting current inrush by con-

necting each phase of the motor windings into a wye configu-

ration. This occurs during the starting period when the motor is

accelerating up to speed. Once the motor is up to speed, the

starter automatically connects the phase windings into a delta

configuration. Starter control, monitoring, and motor protec-

tion is provided by Carrier’s Integrated Starter Module (ISM).

Unit-Mounted VFD (Optional) —

The 19XRV unit

will be equipped with a variable frequency drive motor control-

ler mounted on the unit. See Fig. 7 and 8. This VFD is used

with low voltage motors between 380 and 480 VAC. It reduces

the starting current inrush by controlling the voltage and fre-

quency to the compressor motor. Once the motor has accelerat-

ed to minimum speed the PIC II modulates the compressor

speed and guide vane position to control chilled water tempera-

ture. The VFD is further explained in the Controls section and

Troubleshooting Guide section, pages 10 and 76.

There is a separate display located on the unit-mounted

VFD. Operational parameters and fault codes are displayed rel-

ative to the drive. Refer to specific drive literature along with

troubleshooting sections. The display is also the interface for

entering specific chiller operational parameters. These parame-

ters have been preprogrammed at the factory. An adhesive

backed label on the inside of the drive has been provided for

verification of the specific job parameters. See Initial Start-Up

Checklist section for details.

CONTROLS

Definitions

ANALOG SIGNAL — An analog signal varies in proportion

to the monitored source. It quantifies values between operating

limits. (Example: A temperature sensor is an analog device be-

cause its resistance changes in proportion to the temperature,

generating many values.)

DISCRETE SIGNAL — A discrete signal is a 2-position rep-

resentation of the value of a monitored source. (Example: A

switch produces a discrete signal indicating whether a value is

above or below a set point or boundary by generating an on/off,

high/low, or open/closed signal.)

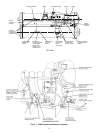

5

1

2

3

6

4

7

LEGEND

Fig. 5 — Solid-State Starter Box,

Internal View

1 — RediStart MICRO™ Input/Output Card

2 — Fuses 1-4 (Hidden, not depicted)

3 — Circuit Breaker 2 (CB2): Machine Control and Heater Power

4 — Circuit Breaker 3 (CB3): Oil Pump Power

5 — RediStart MICRO Central Processing Unit Card (CPU)

6 — RediStart MICRO Power Card (hidden, not depicted)

7 — RediStart MICRO Bypass Card (hidden, not depicted)

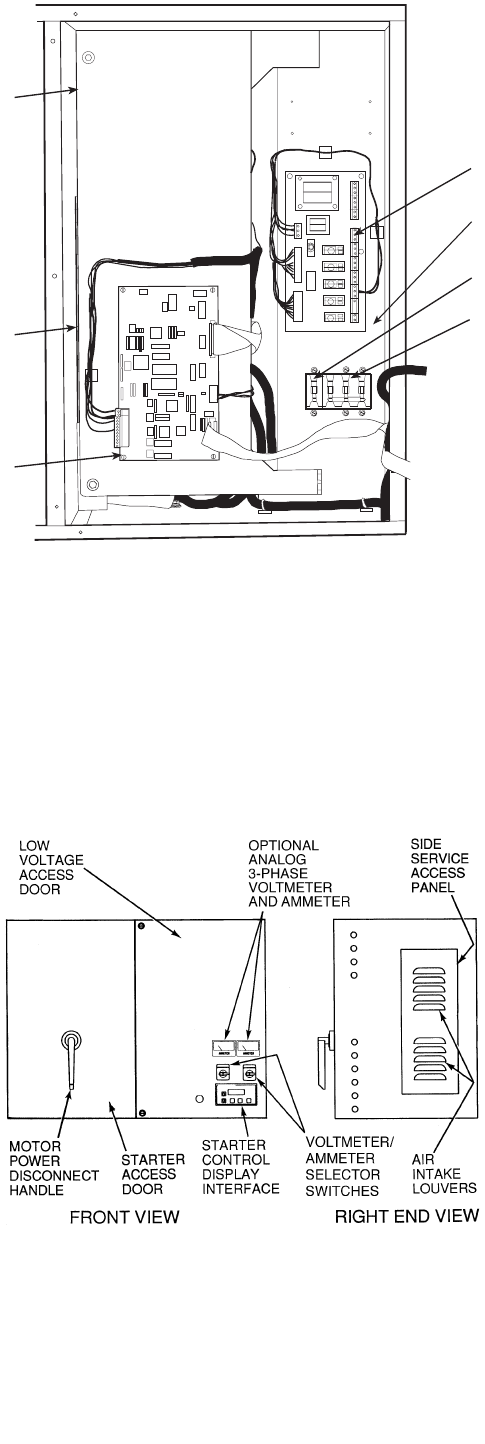

Fig. 6 — Typical Starter External View

(Solid-State Starter Shown)