33

PIC II System Functions

NOTE: Words not part of paragraph headings and printed in all

capital letters can be viewed on the CVC/ICVC (e.g., LOCAL,

CCN, RUNNING, ALARM, etc.). Words printed both in all

capital letters and italics can also be viewed on the CVC/ICVC

and are parameters (CONTROL MODE, TARGET GUIDE

VANE POS, etc.) with associated values (e.g., modes, tempera-

tures, pressures, percentages, on, off, enable, disable, etc.).

Words printed in all capital letters and in a box represent soft-

keys on the CVC/ICVC (e.g., and ). See

Table 2 for examples of the type of information that can appear

on the CVC/ICVC screens. Figures 14-20 give an overview of

CVC/ICVC operations and menus.

CAPACITY CONTROL FIXED SPEED — The PIC II con-

trols the chiller capacity by modulating the inlet guide vanes in

response to chilled water temperature deviation from the CON-

TROL POINT. The CONTROL POINT may be changed by a

CCN network device or is determined by the PIC II adding any

active chilled water reset to the SET POINT. The PIC II uses

the PROPORTIONAL INC (Increase) BAND, PROPOR-

TIONAL DEC (Decrease) BAND, and the PROPORTIONAL

ECW (Entering Chilled Water) GAIN to determine how fast or

slow to respond. CONTROL POINT may be viewed or over-

ridden from the MAINSTAT screen.

CAPACITY CONTROL VFD — The PIC II controls the

machine capacity by modulating the motor speed and inlet

guide vanes in response to chilled water temperature deviation

from the CONTROL POINT. The controller will maintain the

highest inlet guide vane setting at the lowest speed to maxi-

mize efficiency while avoiding surge. The CONTROL POINT

may be changed by a CCN network device or is determined by

the PIC II adding any active chilled water reset to the to the

SET POINT. CONTROL POINT may be viewed or overridden

from the MAINSTAT screen. The PIC II uses the PROPOR-

TIONAL INC (Increase) BAND, PROP DEC (Decrease)

BAND, and the PROPORTIONAL ECW (Entering Chilled

Water) GAIN to determine how fast or slow it takes the system

to respond. The VFD GAIN allows for additional adjustment of

the VFD response. At start-up, the inlet guide vanes (IGV)

start in the closed position and the VFD ramps to its minimum

speed setting.

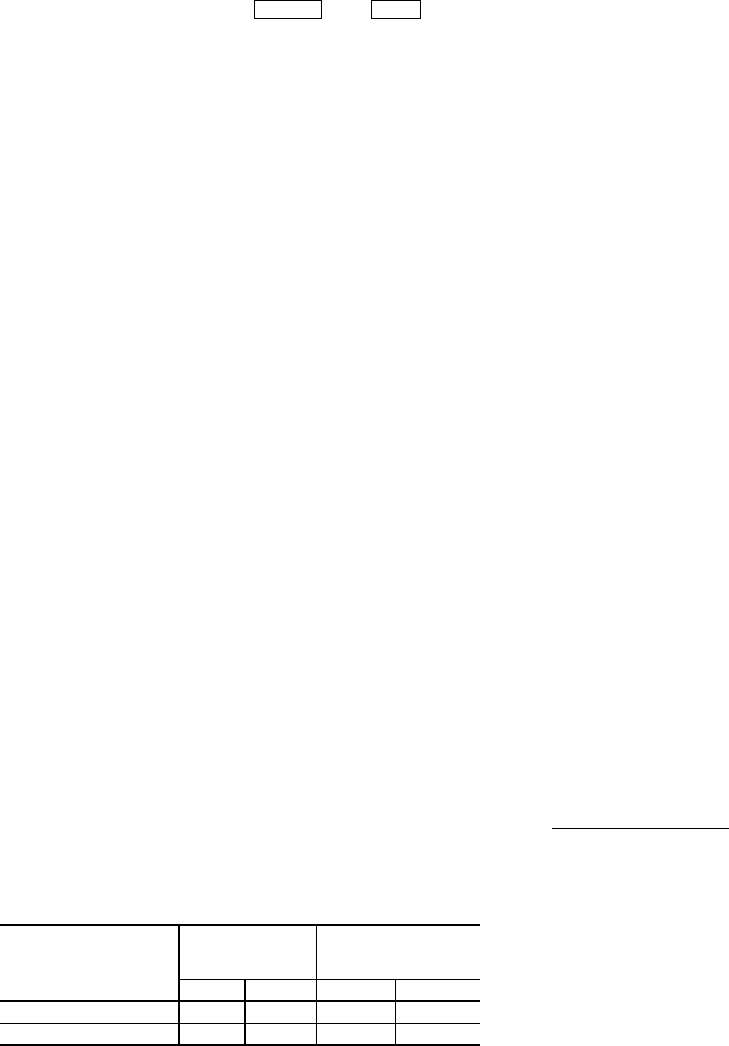

The PIC II controller then initiates the Capacity Control al-

gorithm to maintain the chilled water temperature at the CON-

TROL POINT. During operation when the CONTROL POINT

is not met, the controller will establish a GUIDE VANE DELTA

which will either affect a percentage change to the GUIDE

VANES or the VFD TARGET SPEED. Any change that will be

made to the IGV position or the VFD SPEED will depend on

whether the GUIDE VANE DELTA is positive or negative, and

the status of the Surge Control Algorithm. The Surge Control

Algorithm determines if the chiller should operate in Normal

Mode or Surge Prevention Mode. The logic for how the IGV’s

and VFD SPEED will be affected by the GUIDE VANE DEL-

TA and the Surge Control Algorithm can be seen below:

Normal Control mode occurs when ACTIVE DELTA T >

SURGE/HGBP DELTA T.

Surge Prevention Mode occurs when ACTIVE DELTA T

≤ SURGE/HGBP DELTA T.

The TARGET VFD SPEED, ACTUAL VFD SPEED and the

VFD GAIN can be viewed and modified in the CAPACITY

display screen. The TARGET VFD SPEED can be manually

overridden by the operator from the COMPRESS screen. The

VFD MINIMUM SPEED, MAXIMUM SPEED, VFD GAIN

and INCREASE STEP can be viewed and modified in the

SETUP2 display screen. TARGET and ACTUAL VFD SPEED

can be viewed in the COMPRESS screen.

ECW CONTROL OPTION — If this option is enabled, the

PIC II uses the ENTERING CHILLED WATER temperature to

modulate the vanes instead of the LEAVING CHILLED

WATER temperature. The ECW CONTROL OPTION may be

viewed on the TEMP_CTL screen, which is accessed from the

EQUIPMENT SERVICE screen.

CONTROL POINT DEADBAND — This is the tolerance

range on the chilled water/brine temperature control point. If

the water temperature goes outside the CHILLED WATER

DEADBAND, the PIC II opens or closes the guide vanes until

the temperature is within tolerance. The PIC II may be config-

ured with a 0.5 to 2 F (0.3 to 1.1 C) deadband. CHILLED

WATER DEADBAND may be viewed or modified on the

SETUP1 screen, which is accessed from the EQUIPMENT

SERVICE table.

For example, a 1° F (0.6° C) deadband setting controls the

water temperature within ±0.5° F (0.3° C) of the control point.

This may cause frequent guide vane movement if the chilled

water load fluctuates frequently. A value of 1° F (0.6° C) is the

default setting.

DIFFUSER CONTROL — On 19XR FRAME sizes 4 and

5 compressors equipped with a variable discharge diffuser, the

PIC II adjusts the diffuser actuator position (DIFFUSER

ACTUATOR on the COMPRESS screen) to correspond to the

actual guide vane position (ACTUAL GUIDE VANE POS on

the COMPRESS screen).

The diffuser control can be enabled or disabled from the

SETUP2 screen. See Table 2, Example 19. In addition, the dif-

fuser and guide vane load points may be viewed and modified

from this screen. These points must be correct for the compres-

sor size. The diffuser opening can be incremented from fully

open to completely closed. A 0% setting is fully open; a 100%

setting is completely closed. To obtain the proper settings for

Diffuser Control, contact a Carrier Engineering representative.

PROPORTIONAL BANDS AND GAIN — Proportional band

is the rate at which the guide vane position is corrected in pro-

portion to how far the chilled water/brine temperature is from

the control point. Proportional gain determines how quickly the

guide vanes react to how quickly the temperature is moving

from the CONTROL POINT. The proportional bands and gain

may be viewed or modified from the SETUP2 screen, which is

accessed from the EQUIPMENT SERVICE table.

The Proportional Band

— There are two response modes, one

for temperature response above the control point, the other for

the response below the control point.

The temperature response above the control point is called

the PROPORTIONAL INC BAND, and it can slow or quicken

guide vane response to chilled water/brine temperatures above

the DEADBAND. The PROPORTIONAL INC BAND can be

adjusted from a setting of 2 to 10; the default setting is 6.5.

The response below the control point is called the PRO-

PORTIONAL DEC BAND, and it can slow or quicken the

guide vane response to chilled water temperature below the

deadband plus the control point. The PROPORTIONAL DEC

BAND can be adjusted on the CVC/ICVC from a setting of 2 to

10. The default setting is 6.0.

NOTE: Increasing either of these settings causes the guide

vanes to respond more slowly than they would at a lower

setting.

GUIDE VANE

DELTA

NORMAL

CONTROL

MODE

SURGE

PREVENTION

MODE

IGV VFD IGV VFD

From +0.2 to +2.0 1st 2nd 2nd 1st

From –0.2 to –2.0 2nd 1st 1st —

ENTER EXIT