90

5. Using an ohmmeter, perform the following resistance

measurements and record the results:

If all measured values are greater than 5K ohms, proceed

to Step 10. If any values are less than 5K ohms, one or

more of the SCRs in that pair is shorted.

6. Remove both SCRs in the pair (See SCR Removal/

Installation).

7. Using an ohmmeter, measure the resistance (anode to

cathode) of each SCR to determine which device has

failed.

NOTE: Both SCRs may be defective, but typically, only

one is shorted. If both SCRs provide acceptable resistance

measurements, proceed to Step 10.

8. Replace the defective SCR(s).

9. Retest the “pair” for resistance values indicated above.

10. On the right side of the firing card, measure the resistance

between the red and white gate/cathode leads for each

SCR (1 through 6). A measurement between 5 and

50 ohms is normal. Abnormally high values may indicate

a failed gate for that SCR.

11. Replace the SCRs and retest the pair.

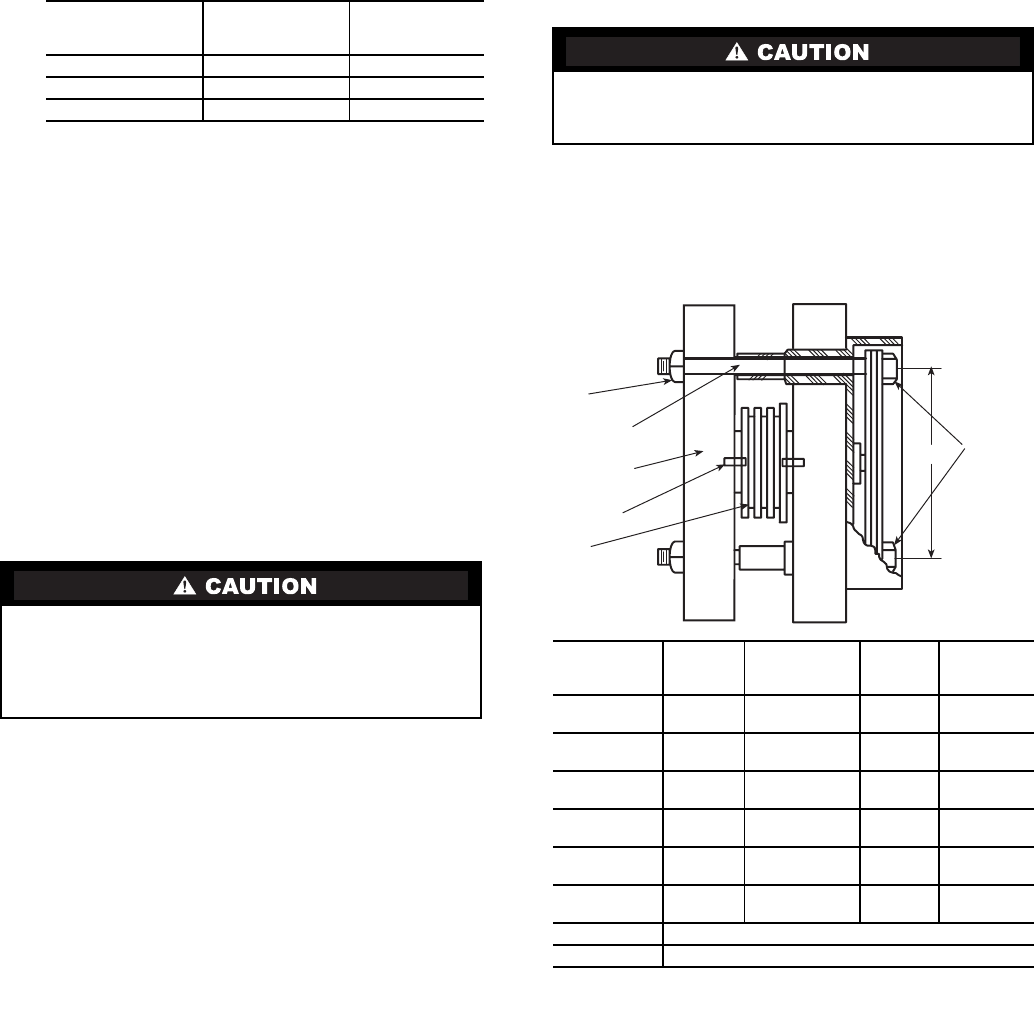

SCR REMOVAL/INSTALLATION — Refer to Fig. 43.

1. Remove the SCR by loosening the clamping bolts on

each side of the SCR,

2. After the SCR has been removed and the bus work is

loose, apply a thin coat of either silicon based thermal

joint compound or a joint compound for aluminum or

copper wire connections to the contact surfaces of the re-

placement SCR. This allows for improved heat dissipa-

tion and electrical conductivity.

3. Place the SCR between the roll pins on the heatsink

assemblies so the roll pins fit into the small holes in each

side of the SCR.

NOTE: Ensure the SCR is installed so the cathode side is

the side from which the red wire extends. The heatsink is

labeled to show the correct orientation.

4. Hand tighten the bolts until the SCR contacts the

heatsink.

5. Using quarter-turn increments, alternating between

clamping bolts, apply the appropriate number of whole

turns referencing the table in Fig. 43.

6. Reconnect the red (cathode) wire from the SCR and the

white (anode-gate) wire to the appropriate location on the

firing card (i.e., SCR1 wires to firing card terminal

G1-white wire, and K1-red wire).

7. Reconnect all other wiring and bus work.

8. Return starter to normal operation.

Physical Data —

Tables 13A-20 and Fig. 44-57 provide

additional information on component weights, compressor fits

and clearances, physical and electrical data, and wiring sche-

matics for the operator’s convenience during troubleshooting.

MEASURE

BETWEEN

SCR PAIRS

BEING

CHECKED

RECORDED

VALUE

T1 and T6 3 and 6

T2 and T4 2 and 5

T3 and T5 1 and 4

If any red or white SCR gate leads are removed from the

firing card or an SCR, care must be taken to ensure the

leads are replaced EXACTLY as they were (white wires to

gates, and red wires to cathodes on both the firing card and

SCR), or damage to the starter and/or motor may result.

Care must be taken to prevent nut rotation while tightening

the bolts. If the nut rotates while tightening the bolt, SCR

replacement must be started over.

Fig. 43 — SCR Installation

SCR PART

NUMBER

BISCR

CLAMP

SIZE

A

DIMENSION

(in.)

NO. OF

TURNS

BOLT

LENGTH

(in.)

6601218 1030

2.75

(70 mm)

1

1

/

2

3.0

(76 mm)

6601818 1030

2.75

(70 mm)

1

1

/

2

3.0

(76 mm)

8801230 1035

2.75

(70 mm)

1

3

/

4

3.5

(89 mm)

8801830 1035

2.75

(70 mm)

1

3

/

4

3.0

(89 mm)

15001850 2040

4.00

(102 mm)

2

3

/

4

4.0

(102 mm)

15001850 2050

4.00

(102 mm)

2

3

/

4

5.0

(127 mm)

220012100 Consult Benshaw Representative

330018500 Consult Benshaw Representative

LOOSEN

AND

TIGHTEN

BOLTS

FROM

THIS END

CLAMPING

BOLT

NUT

ALUMINUM

HEATSINK

ROLL PIN

SCR

A