39

(see wiring diagrams or certified drawings). The temperature

sensor must be wired to terminal J4-13 and J4-14. To configure

Reset Type 2, enter the temperature of the remote sensor at the

point where no temperature reset will occur (REMOTE TEMP

–> NO RESET). Next, enter the temperature at which the full

amount of reset will occur (REMOTE TEMP –> FULL

RESET). Then, enter the maximum amount of reset required to

operate the chiller (DEGREES RESET). Reset Type 2 can now

be activated.

RESET TYPE 3 — Reset Type 3 is an automatic chilled water

temperature reset based on cooler temperature difference.

Reset Type 3 adds ± 30° F (± 16° C) based on the temperature

difference between the entering and leaving chilled water

temperature.

To configure Reset Type 3, enter the chilled water tempera-

ture difference (the difference between entering and leaving

chilled water) at which no temperature reset occurs (CHW

DELTA T –> NO RESET). This chilled water temperature dif-

ference is usually the full design load temperature difference.

Next, enter the difference in chilled water temperature at which

the full amount of reset occurs (CHW DELTA T –> FULL RE-

SET). Finally, enter the amount of reset (DEGREES RESET).

Reset Type 3 can now be activated.

Demand Limit Control Option —

The demand limit

control option (20 mA DEMAND LIMIT OPT) is externally

controlled by a 4 to 20 mA or 1 to 5 vdc signal from an energy

management system (EMS). The option is set up on the

RAMP_DEM screen. When enabled, 4 mA is the 100% de-

mand set point with an operator-configured minimum demand

at a 20 mA set point (DEMAND LIMIT AT 20 mA).

The auto. demand limit is hardwired to terminals J5-1 (–)

and J5-2 (+) on the CCM. Switch setting number 1 on SW2

will determine the type of input signal. With the switch set at

the ON position the input is configured for an externally pow-

ered 4 to 20 mA signal. With the switch in the OFF position the

input is configured for an external 1 to 5 vdc signal.

Surge Prevention Algorithm (Fixed Speed

Chiller) —

This is an operator-configurable feature that can

determine if lift conditions are too high for the compressor and

then take corrective action. Lift is defined as the difference be-

tween the pressure at the impeller eye and at the impeller

discharge. The maximum lift a particular impeller wheel can

perform varies with the gas flow across the impeller and the

size of the wheel.

A surge condition occurs when the lift becomes so high the

gas flow across the impeller reverses. This condition can even-

tually cause chiller damage. The surge prevention algorithm

notifies the operator that chiller operating conditions are mar-

ginal and to take action to help prevent chiller damage such as

lowering entering condenser water temperature.

The surge prevention algorithm first determines if correc-

tive action is necessary. The algorithm checks 2 sets of opera-

tor-configured data points, the minimum load points (MIN.

LOAD POINT [T1,P1]) and the full load points (FULL LOAD

POINT [T2,P2]). These points have default settings as defined

on the OPTIONS screen or on Table 4.

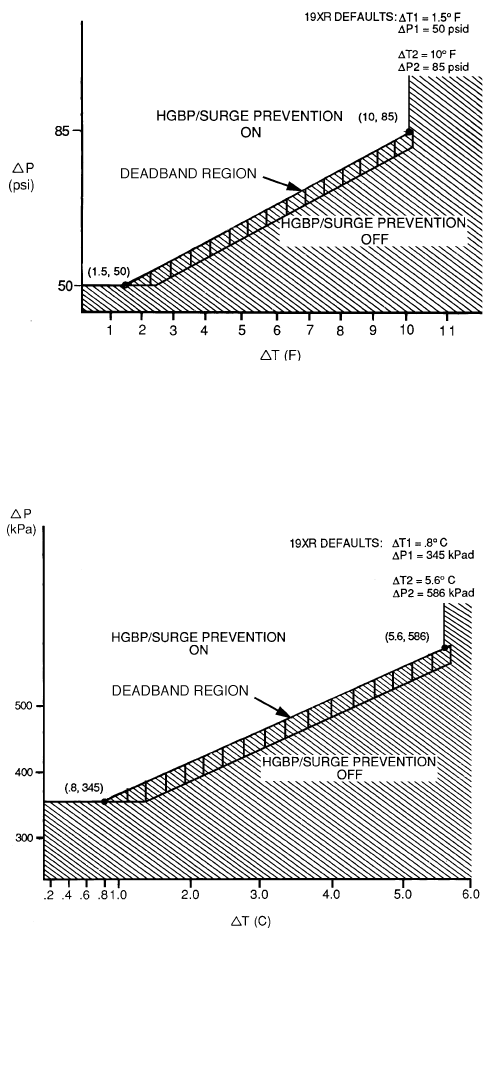

The surge prevention algorithm function and settings are

graphically displayed in Fig. 21 and 22. The two sets of load

points on the graph (default settings are shown) describe a line

the algorithm uses to determine the maximum lift of the com-

pressor. When the actual differential pressure between the cool-

er and condenser and the temperature difference between the

entering and leaving chilled water are above the line on the

graph (as defined by the minimum and full load points), the al-

gorithm goes into a corrective action mode. If the actual values

are below the line and outside of the deadband region, the algo-

rithm takes no action. When the point defined by the ACTIVE

DELTA P and ACTIVE DELTA T, moves from the region

where the HOT GAS BYPASS/SURGE PREVENTION is off,

the point must pass through the deadband region to the line

determined by the configured values before the HOT GAS

BYPASS/SURGE PREVENTION will be turned on. As the

point moves from the region where the HOT GAS BYPASS/

SURGE PREVENTION is on, the point must pass through the

deadband region before the HOT GAS BYPASS/SURGE

PREVENTION is turned off. Information on modifying the de-

fault set points of the minimum and full load points may be

found in the Input Service Configurations section, page 55.

The state of the surge/hot gas bypass algorithm on the

HEAT_EX DISPLAY SCREEN (Surge/HGBP Active?).

Corrective action can be taken by making one of 2 choices.

If a hot gas bypass line is present and the hot gas option is

selected on the OPTIONS table (SURGE LIMIT/HGBP

OPTION is set to 1), the hot gas bypass valve can be energized.

If the hot gas bypass option is not selected (SURGE LIMIT/

HGBP OPTION is set to 0), hold the guide vanes. See Table 4,

LEGEND

∆P = (Condenser Psi) – (Cooler Psi)

∆T = (ECW) – (LCW)

Fig. 21 — 19XR Hot Gas Bypass/Surge

Prevention with Default English Settings

ECW — Entering Chilled Water

HGBP — Hot Gas Bypass

LCW — Leaving Chilled Water

LEGEND

∆P = (Condenser kPa) – (Cooler kPa)

∆T = (ECW) – (LCW)

Fig. 22 — 19XR Hot Gas Bypass/Surge

Prevention with Default Metric Settings

ECW — Entering Chilled Water

HGBP — Hot Gas Bypass

LCW — Leaving Chilled Water