53

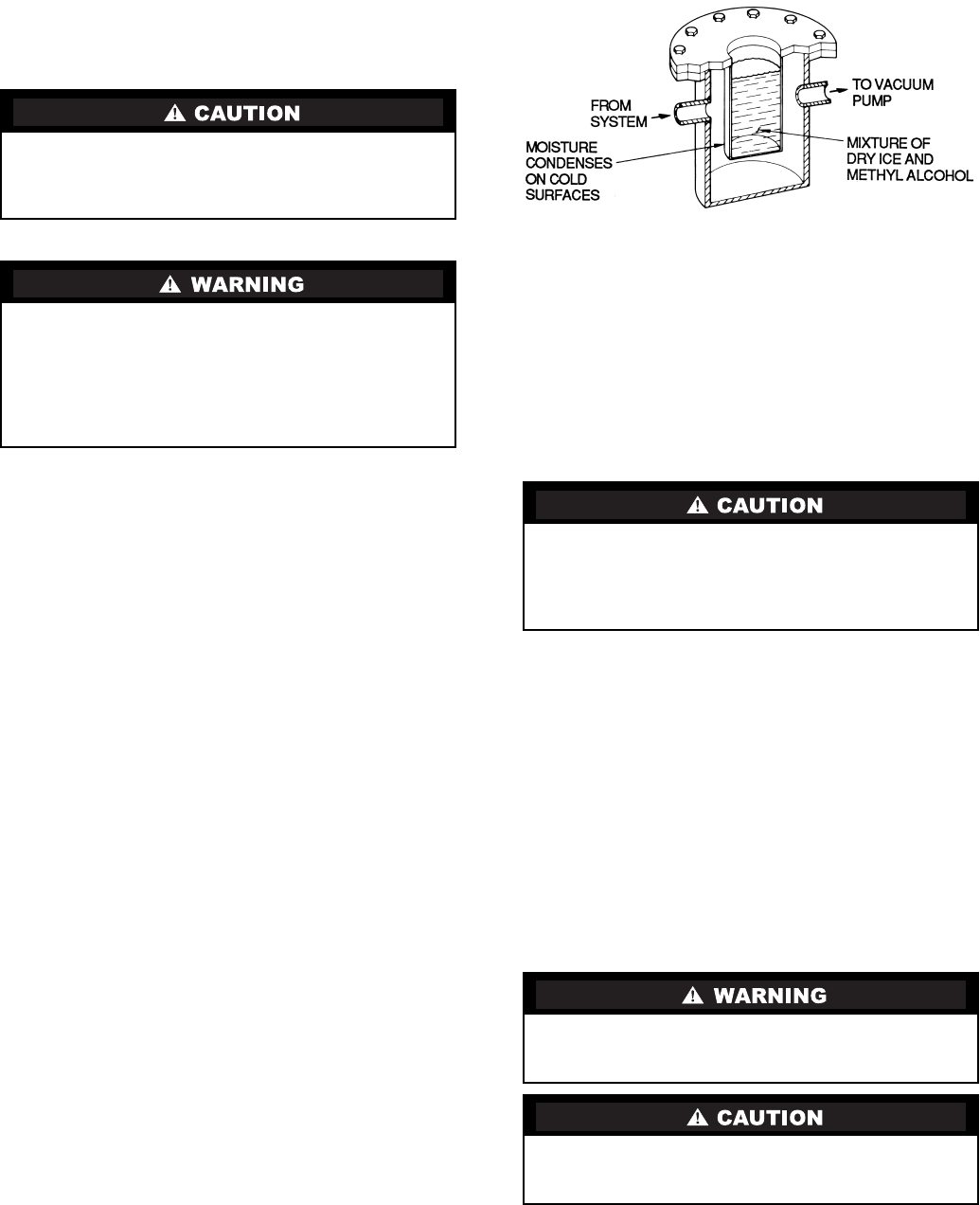

Chiller Dehydration —

Dehydration is recommended if

the chiller has been open for a considerable period of time, if

the chiller is known to contain moisture, or if there has been a

complete loss of chiller holding charge or refrigerant pressure.

Dehydration can be done at room temperatures. Using a

cold trap (Fig. 31) may substantially reduce the time required

to complete the dehydration. The higher the room temperature,

the faster dehydration takes place. At low room temperatures, a

very deep vacuum is required to boil off any moisture. If low

ambient temperatures are involved, contact a qualified service

representative for the dehydration techniques required.

Perform dehydration as follows:

1. Connect a high capacity vacuum pump (5 cfm [.002 m

3

/s]

or larger is recommended) to the refrigerant charging

valve (Fig. 2). Tubing from the pump to the chiller should

be as short in length and as large in diameter as possible to

provide least resistance to gas flow.

2. Use an absolute pressure manometer or a wet bulb vacu-

um indicator to measure the vacuum. Open the shutoff

valve to the vacuum indicator only when taking a read-

ing. Leave the valve open for 3 minutes to allow the indi-

cator vacuum to equalize with the chiller vacuum.

3. If the entire chiller is to be dehydrated, open all isolation

valves (if present).

4. With the chiller ambient temperature at 60 F (15.6 C) or

higher, operate the vacuum pump until the manometer

reads 29.8 in. Hg vac, ref 30 in. bar. (0.1 psia)

(–100.61 kPa) or a vacuum indicator reads 35 F (1.7 C).

Operate the pump an additional 2 hours.

Do not apply a greater vacuum than 29.82 in. Hg vac

(757.4 mm Hg) or go below 33 F (.56 C) on the wet bulb

vacuum indicator. At this temperature and pressure, iso-

lated pockets of moisture can turn into ice. The slow rate

of evaporation (sublimation) of ice at these low tempera-

tures and pressures greatly increases dehydration time.

5. Valve off the vacuum pump, stop the pump, and record

the instrument reading.

6. After a 2-hour wait, take another instrument reading. If

the reading has not changed, dehydration is complete. If

the reading indicates vacuum loss, repeat Steps 4 and 5.

7. If the reading continues to change after several attempts,

perform a leak test up to the maximum 160 psig

(1103 kPa) pressure. Locate and repair the leak, and re-

peat dehydration.

Inspect Water Piping —

Refer to piping diagrams pro-

vided in the certified drawings and the piping instructions in

the 19XR Installation Instructions manual. Inspect the piping to

the cooler and condenser. Be sure that the flow directions are

correct and that all piping specifications have been met.

Piping systems must be properly vented with no stress on

waterbox nozzles and covers. Water flows through the cooler

and condenser must meet job requirements. Measure the pres-

sure drop across the cooler and the condenser.

Check Optional Pumpout Compressor Water

Piping —

If the optional pumpout storage tank and/or

pumpout system are installed, check to ensure the pumpout

condenser water has been piped in. Check for field-supplied

shutoff valves and controls as specified in the job data. Check

for refrigerant leaks on field-installed piping. See Fig. 29

and 30.

Check Relief Valves —

Be sure the relief valves have

been piped to the outdoors in compliance with the latest edition

of ANSI/ASHRAE Standard 15 and applicable local safety

codes. Piping connections must allow for access to the valve

mechanism for periodic inspection and leak testing.

The 19XR relief valves are set to relieve at the 185 psig

(1275 kPa) chiller design pressure.

Inspect Wiring

1. Examine the wiring for conformance to the job wiring di-

agrams and all applicable electrical codes.

Do not start or megohm-test the compressor motor or oil

pump motor, even for a rotation check, if the chiller is

under dehydration vacuum. Insulation breakdown and

severe damage may result.

Inside-delta type starters must be disconnected by an isola-

tion switch before placing the machine under a vacuum

because one lead of each phase is live with respect to

ground even though there is not a complete circuit to run

the motor. To be safe, isolate any starter before evacuating

the chiller if you are not sure if there are live leads to the

hermetic motor.

Water must be within design limits, clean, and treated to

ensure proper chiller performance and to reduce the poten-

tial of tube damage due to corrosion, scaling, or erosion.

Carrier assumes no responsibility for chiller damage result-

ing from untreated or improperly treated water.

Do not check the voltage supply without proper equipment

and precautions. Serious injury may result. Follow power

company recommendations.

Do not apply any kind of test voltage, even for a rotation

check, if the chiller is under a dehydration vacuum. Insula-

tion breakdown and serious damage may result.

Fig. 31 — Dehydration Cold Trap