37

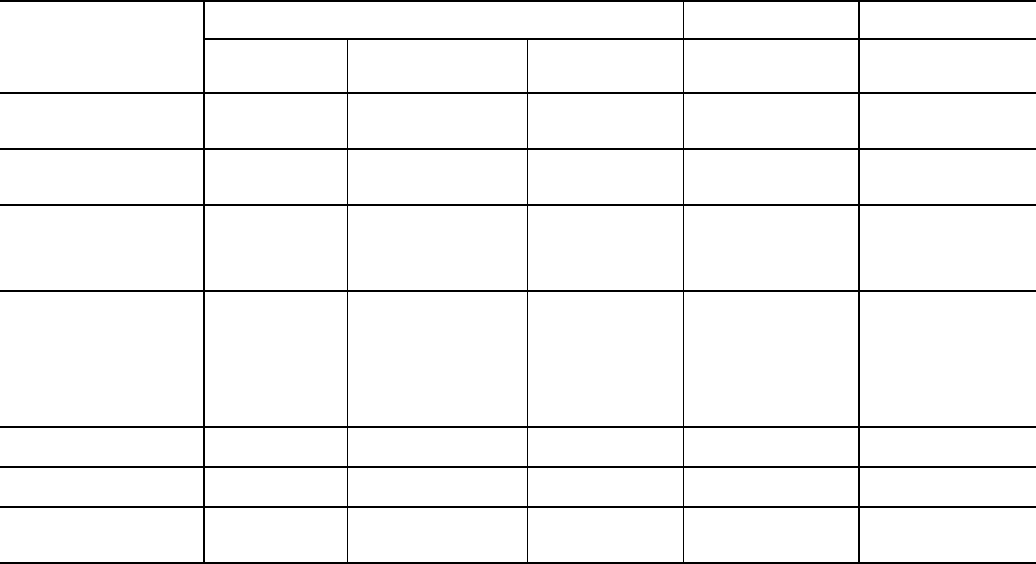

Table 4 — Capacity Overrides

Alarm (Trip) Output Contacts —

One set of alarm

contacts is provided in the starter. The contact ratings are pro-

vided in the certified drawings. The contacts are located on ter-

minal strip J9, terminals 15 and 16.

Refrigerant Leak Detector —

An input is available

on the CCM module [terminal J5-5 (–) and J5-6 (+)] for a

refrigerant leak detector. Enabling REFRIGERANT LEAK

OPTION (OPTIONS screen) will allow the PIC II controls to

go into an alarm state at a user configured level (REFRIGER-

ANT LEAK ALARM mA). The input is configured for 4 to

20 mA by setting the DIP switch 1 on SW2 at the ON position,

or configured for 1 to 5 vdc by setting switch 1 at the OFF posi-

tion. The output of the refrigerant leak detector is displayed as

REFRIGERANT LEAK SENSOR on the MAINSTAT screen.

For a 1 to 5 vdc input, 1 vdc input represents 4 mA displayed

and 5 vdc input represents 20 mA displayed.

Kilowatt Output —

An output is available on the CCM

module [Terminal J8-1 (+) and J8-2 (–)] to represent the power

consumption of the chiller. The 4 to 20 mA signal generated by

the CCM module can be wired to the building automation or

energy management system to monitor the chiller’s energy

consumption. A 4 mA signal represents the chiller in an off

state and a 20 mA signal represents the chiller operating at its

rated peak kilowatt consumption. The rated peak kilowatt con-

sumption is configured by the user in the RAMP_DEM display

screen by the setting the MOTOR RATED KILOWATTS from

the job data sheet.

Remote Reset of Alarms —

A standard feature of the

PIC II controls is the ability to reset a chiller in a shutdown

alarm state from a remote location. If the condition which

caused the alarm has cleared the chiller can be placed back into

a normal CCN operating mode when the REMOTE RESET

OPTION (CVC_PSWD/ICVC_PSWD menu) is set to EN-

ABLE. A variety of Carrier Comfort Network software sys-

tems including ComfortVIEW™ or Network Service Tool™

can access the PIC II controls and reset the displayed alarm.

Third party software from building automation systems (BAS)

or energy management systems (EMS) can also access the

PIC II controls through a Carrier DataLINK™ module and re-

set the fault displayed. Both methods would access the

CVC_PSWD/ICVC_PSWD screen and force the RESET

ALARM? point to YES to reset the fault condition. If the PIC II

controls have determined that is safe to start the chiller the

CCN MODE? point (CVC_PSWD/ICVC_PSWD screen) can

be forced to YES to place the chiller back into normal CCN op-

erating mode. The only exceptions are the following alarms

that cannot be reset from a remote location: STATE #100, 205,

217-220, 223, 233, 234, 247, and 250. To view alarm codes, re-

fer to Troubleshooting Guide, Checking Display Messages,

page 76. After the alarm has been reset the PIC II control will

increment the Starts in 12 Hours counter by one upon restart. If

the limit of 8 starts in a 12-hour period occurs the alarm will be

required to be reset at the chiller control panel (CVC/ICVC).

Condenser Pump Control —

The chiller will moni-

tor the condenser pressure (CONDENSER PRESSURE) and

may turn on the condenser pump if the condenser pressure be-

comes too high while the compressor is shut down. The con-

denser pressure override (COND PRESS OVERRIDE) parame-

ter is used to determine this pressure point. COND PRESS

OVERRIDE is found in the SETUP1 display screen, which is

accessed from the EQUIPMENT SERVICE table. The default

value is 125 psig (862 kPa).

If the CONDENSER PRESSURE is greater than or equal to

the COND PRESS OVERRIDE, and the entering condenser

water temperature (ENTERING CONDENSER WATER) is less

than 115 F (46 C), the condenser pump will energize to try to

decrease the pressure. The pump will turn off when the con-

denser pressure is 3.5 psi (24.1 kPa) less than the pressure over-

ride or when the condenser refrigerant temperature (CON-

DENSER REFRIG TEMP) is within 3° F (1.7° C) of the enter-

ing condenser water temperature (ENTERING CONDENSER

WATER).

OVERRIDE

CAPACITY CONTROL

FIRST STAGE SET POINT

SECOND STAGE SET

POINT

OVERRIDE

TERMINATION

View/Modify

on CVC/ICVC

Screen

Default

Value

Configurable

Range

Value Value

HIGH CONDENSER

PRESSURE

SETUP1

125 psig

(862 kPa)

90 to 165 psig

(620 to 1138 kPa)

>Override

Set Point

+2.4 psid (16.5 kPad)

<Override

Set Point

HIGH MOTOR

TEMPERATURE

SETUP1

>200 F

(93.3 C)

150 to 200 F

(66 to 93 C)

>Override

Set Point

+10° F (6° C)

<Override

Set Point

LOW REFRIGERANT

TEMPERATURE

(Refrigerant

Override Delta

Temperature)

SETUP1 3° F (1.6° C)

2° to 5° F

(1° to 3° C)

≤Trippoint

+ Override

∆T –1° F (0.56° C)

>Trippoint

+ Override

∆T+2° F (1.2° C)

HIGH COMPRESSOR

LIFT

(Surge Prevention)

OPTIONS

Min: T1 — 1.5° F

(0.8° C)

P1 — 50 psid

(345 kPad)

Max: T2 — 10° F

(5.6° C)

P2 — 85 psid

(586 kPad)

0.5° to 20° F

(0.3° to 8.3° C)

30 to 170 psid

(207 to 1172 kPad)

0.5° to 20° F

(0.3° to 8.3° C)

50 to 170 psid

(348 to 1172 kPad)

None

Within Lift Limits

Plus Surge/HGBP

Deadband Setting

MANUAL GUIDE VANE

TARGET

CAPACITY Automatic 0 to 100% None

Release of

Manual Control

MOTOR LOAD —

ACTIVE DEMAND LIMIT

MAINSTAT 100% 40 to 100%

≥5% of

Set Point

2% Lower

Than Set Point

LOW DISCHARGE

SUPERHEAT

OVERRIDE

Calculated Minimum

Superheat for

Conditions

None

2° F (1.1° C)

Below Calculated

Minimum Superheat

1° F (0.56° C)

Above Calculated

Minimum Superheat