3-6T-268-07

3.1.4 Controller Function Codes

There are thirty-nine functions which the operator may

access to examine the operating status of the unit. To

access these functions, perform the following steps:

Press the CODE SELECT key, then press an arrow key

until the left window displays the desired code number

(seeTable 3-3). For the display only function codes,the

right window will display the value of this item for five

seconds before returning to the normal display mode. If

a longer time is desired, pressing the ENTER key will

extend the time to 30 seconds after the last pressing of

the ENTER key. Function codes are explained in

Table 3-3.

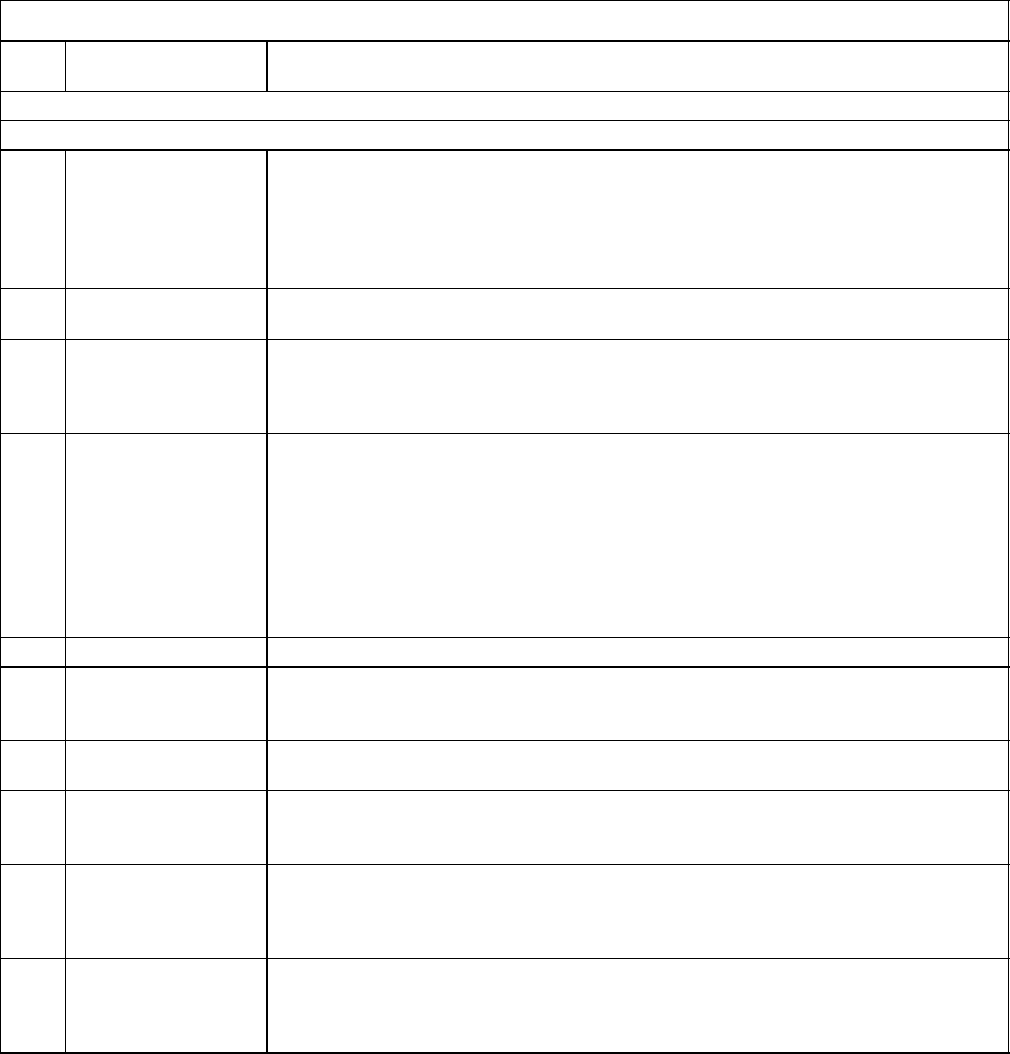

Table 3-3. Controller Function Code Assignments

CODE

#

TITLE DESCRIPTION

Inapplicable Functions Display ----------

Display Only Functions

Cd01

Modulation Valve

Opening (%)

The suction modulation valve (SMV) is a normally open valve which restricts flow

of refrigerant to the compressor when energized by a pulse width modulated

(PWM) output. The amount of valve closure is proportional to the applied current

over the range of 0.2 to 1.3 A. The valve is completely open (right display reads

100%) below 0.2 amps and is completely closed (right display reads 0%) at 1.3

amps.

Cd02

Quench Valve

(Open--Closed)

Shows state of the solenoid quench valve, if so equipped (open or closed).

Cd03

Suction Solenoid

Valve

(Open--Closed)

The suction solenoid valve (SSV) provides maximum refrigerant flow to the

refrigeration unit. This valve will always be open for set points at or below --10_C

(+14_F), or --5_C(+23_F) optionally, and during temperature pulldown periods

unless suction solenoid override or current limiting restricts its use.

Cd04

Cd05

Cd06

Line Current, Phase

A

Line Current, Phase

B

Line Current, Phase

C

Unit current is monitored by two current sensors. The current measured is used

for control and diagnostic purposes.For control processing, the highest of the

Phase A and B current values is used for current limiting purposes. The third

unmeasured leg is calculated based on a current algorithm. For diagnostic

processing, the current draws are used to determine control unit operations.

Whenever a heater or a motor is turned ON or OFF, the current draw

increase/reduction for that activity is measured. The current draw is then tested to

determine if it falls within the expected range of values for the unit. Failure of this

test will result in a pre-trip failure or a control alarm indication.

Cd07 Main Power Voltage The main supply voltage is displayed.

Cd08

Mains Power

Frequency

The value of the main power frequency is displayed in Hertz. The frequency

displayed will be halved if either fuse F1 or F2 is bad and alarm code AL21 is

active.

Cd09

Ambient

Temperature

The ambient sensor (AMBS) measures the temperature outside the container.

For location of the sensor, see Figure 2-5.

Cd10

Compressor Suction

Temperature

(Optional)

Compressor suction temperature is measured just prior to the compressor suction

service valve, and is a display-only temperature.

Cd11

Compressor

Discharge

Temperature

(Optional)

The compressor discharge temperature is measured near the compressor

discharge valve and is display only.

Cd12

Compressor Suction

Pressure (Optional)

Compressor suction pressure is displayed using a pressure transducer. Pressure

is displayed in units of psig when code 28 is set to _F and units of bars when

code 28 is set to _C. “P” appears after the value to indicate psig, “b” appears after

the value to indicate bars and “i” appears after the value for inches of mercury.