Demand Control Software Overview • 11-35

proof latch time.

11.10.9 Output Light Dimming

The dimming feature allows the lighting output to be

varied based on a light level sensor. Dimming capability

can work with both Standard Control and Alternate Con-

trol configuration. For setup, the user can:

• Specify the light levels for the minimum and maxi-

mum light output.

• Specify the ramp speed that the indoor lighting out-

put changes.

11.11 Demand Control

Demand Control applications are used by E2 to keep

the total power usage of the building environmental sys-

tem below a specific demand setpoint dictated by the

pow

er company. Demand Control applications achieve

this by reducing power consumption in one or more appli-

cations in the other E2 applications

as necessary until the

total KW is below the setpoint. This process is called load

shedding.

The Demand Control application

is designed to calcu-

late power usage in much the

same way power companies

do, which ensures that it will be able to meet the power

company’s demand limit accurately. The Demand Control

application is also designed with a large amount of flexi-

bility in the way load shedding i

s prioritized, which allows

users to maximize power economization with a minimal

amount of interference into the normal operations of the

building’s HVAC systems.

11.11.1 Introduction to Demand

Limit Control

Power companies supply power to consumers at a

fixed rate per kilowatt hour until a pre-defined level of

energy consumption is reached. This level is called the

demand limit. When the demand limit is exceeded, the

rate is greatly increased as a penalty for high power

demand by the consumer. Typically, once the demand limit

is exceeded, the increased rate is charged for the remain-

der of the year.

To determine if a consumer has reached the demand

lim

it, the power company arbitrarily monitors a con-

sumer’s energy consumption for a fixed period of time

(u

sually anywhere from 15 to 30 minutes with most power

companies, although it may be as short as 5 minutes). This

monitoring period is called the demand window. Demand

windows are always the same length of time, but they may

be measured at any time the power company chooses to.

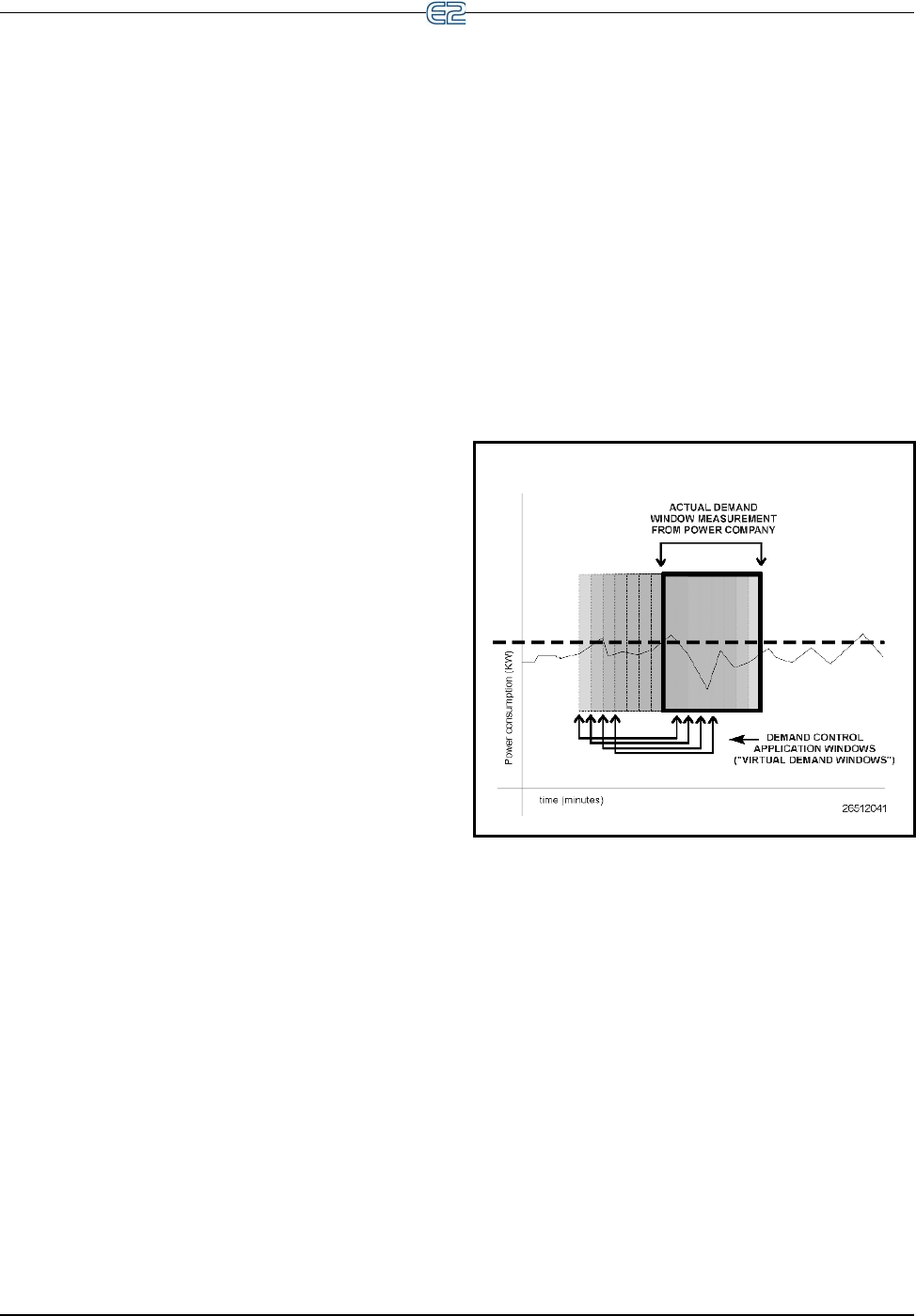

Since Demand Control applications have no way of

det

ermining when the power company will start a demand

window, they simply assume that the demand window can

begin at any time. As new values of the KW input are

gathered, Demand Control applications “roll” their

demand windows forward and recalculate their load shed-

ding algorithms as if the power company

were measuring

the average power of the new window.

For example, if the power company’s demand window

lasts for 1

5 minutes, the Demand Control applications will

keep a constant real-time average of all recorded KW val-

ues from the previous 15 minutes. If a Demand Control

app

lication determines from its calculations that the cur-

rent KW usage might cause its demand limit to be

exceeded for the current

or a future demand window, it

will begin shedding loads to bring the KW usage down. A

graphic example of the “rolling demand window” used by

the Demand Control application is shown in Figure 11-20.

Figure 11-20

- Example of “Rolling Demand Window”

In short, the primary goal of a Demand Control appli-

cation is to make sure that every possibl

e interval of time

that might be used by the power company as a demand

window will be under the set demand limit. This ensures

the demand setpoint will never be exceeded.

11.11.2 Demand Monitoring

The E2 either monitors power using an analog KW

transducer (which sends the current KW usage via analog

signal), or monitors energy consumption using a digital

watt-hour transducer (which pulses to signify a fixed

amount of watt-hours have been used).

As mentioned in Section 11.11.1, Int

roduction to

Demand Limit Control, all KW input values are gathered

together and averaged together in a demand window. The

dem

and setpoint is then subtracted from this average. The

result of this calculation is called the integral error (or