D-4 • E2 RX/BX/CX I&O Manual 026-1614 Rev 4 5-JAN-2013

sate for error.

To reduce this lag time, Derivative Mode is used.

Derivative Mode constantly analyzes the rate of change of

the error, makes a prediction about what the future error

will be, and makes an adjustment to the output in an

attempt to reduce the rate of change in the error.

In layman’s terms, Derivative Mode causes PID con-

trol to “overshoot” the amount of output percentage to

compensate for the slow reaction times of the P and I

Modes. As a result, Derivative Mode slows the rate error

change down to a level the P and I Modes can handle.

The “D” Mode Calculation

To determine the “D” Mode adjustment for each

update, PID performs the following calculation:

“D” mode adjustment = K

d

* (E – (2E

-1

/t

-1

)+(E

-2

/t

-2

))

K

d

= derivative gain

E = current error

E

-1

=error from the previous update

t

-1

=the amount of time elapsed since the previous exe-

cution

E

-2

=error from the update before the previous update

t

-2

=the amount of time elapsed between 2 executions

ago and the previous execution

The factors E

-1

/t

-1

and

E

-2

/t

-2

are the rates of change

of the error (in units per minute). The rate of change for

the previous error (E

-1

) weighs twice as much in the

Derivative Mode calculation as the 2

nd

previous error (E

-

2

), since E

-1

is closer to the current rate of change than E

-2

.

The derivative gain K

d

is a multiplier that changes the

total size of the Derivative Mode adjustment. If Derivative

Mode is causing PID control to react too quickly or too

slowly, the derivative gain may be adjusted to correct the

problem. Higher values of K

d

result in quicker reactions;

lower values result in slower reactions.

How Condenser Control and

HVAC PID Differs From The

Others

The RMCC approaches condenser control and HVAC

control from a different angle than other PID-controlled

systems such as Pressure Control and Case Control. PID

control for Pressure Control and Case Control seeks to

maintain a constant equality between the input and the set

-

point. Specifically, in Pressure Control, the RMCC tries to

keep the suction pressure or temperature equal to the suc

-

tion setpoint, and in Case Control, the RMCC tries to keep

the case temperature equal to the temperature setpoint.

Condenser Control and HVAC Control seek only to

keep pressure or temperature values

below or above their

setpoints. Thus, the system is only concerned when the

input value is on the wrong side of the setpoint (e.g., above

the setpoint in Condenser Control and Cooling Control, or

below the setpoint in Heating Control). Any value on the

other side of the setpoint is considered an acceptable value

for the purposes of controlling, and therefore the output

will be at or near 0%.

Condenser PID and HVAC Cooling Control only react

to pressure or temperature levels that climb above the set

-

point. Likewise, in HVAC Heating Control, the tempera-

ture level must be below the heating setpoint in order to

begin heating. The 0-100% output percentage is then

determined based on the distance between the input and

setpoint, and the rate of change.

Output at Setpoint

Mathematically, the only difference between PID for

Condenser and HVAC Control and PID for other systems

is the Output at Setpoint value.

The Output at Setpoint value is simply the percentage

the output will be when the input value is stabilized at the

setpoint. In other words, when the PID input equals the

PID setpoint, the PID output percentage will be fixed at

the Output at Setpoint value.

Output at Setpoint is the value that determines where

the throttling range is placed. As mentioned in “Throttling

Range” on page 1, the Throttling Range is the range of

input values across which Proportional Mode will gradu

-

ally move the output percentage from 0% to 100%

(excluding effects by the Integral and Derivative Modes).

The Output at Setpoint value basically tells the RMCC

where to place the Throttling Range in relation to the set

-

point (this is explained in further detail below).

Output at Setpoint for Non-Condenser/

HVAC PID

For all non-condenser and non-HVAC PID control, the

Output at Setpoint is fixed at 50% (except for Analog Out

-

put Modules, which may be programmed with any value

from 0-100%). As mentioned before, this means that PID

control will constantly strive to achieve a stable system

where the input is equal to the setpoint and the output is

50%.

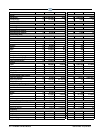

The throttling range in a PID Control application with

a 50% Output at Setpoint is placed in such a way as to put

the setpoint right in the middle of the throttling range, as

shown in

Figure D-3.