11-46 • E2 RX/BX/CX I&O Manual 026-1614 Rev 4 5-JAN-2013

power monitoring inputs will appear under the Inputs tab

of the application. All inputs must be connected to board

and points set up with Engineering Units of Amps.

11.16 Anti-Sweat Setup

An anti-sweat application controls one anti-sweat

zone. An anti-sweat zone is defined as one or more anti-

sweat heaters that use the same dewpoint (or RH and tem-

perature) sensors and the same control setpoints. If all the

out

puts on a 20-channel PMAC panel are going to use the

same setpoints and dewpoint device(s), then all the heaters

may be set up in a single zone.

Zones are set up in a single screen called the Anti-

Sweat

Control Setup screen.

11.16.1 How Anti-Sweat Works

Anti-sweat applications control anti-sweat heaters by

monitoring the dewpoint. A dewpoint value may come

from a dewpoint probe mounted within the Zone, or it may

be calculated automatically by the E2 using a combination

of a relative humidity sensor and a temperature sensor.

The dewpoint value is used to pulse the heaters ON for

a certain percentage of

a user-defined time interval. The

dewpoint is compared to the anti-sweat application’s con-

trol setpoints (the Full ON Dewpoint and the Full OFF

Dewp

oint). Based on this comparison, the anti-sweat heat-

ers will do one of three things:

• If the dewpoint is equal to or above the Full ON

Dewp

oint, the heaters remain ON 100% of the time.

• If the dewpoint is equal to or below the Full OFF

Dewpoint, the

heaters will be ON 0% of the time

(fully OFF).

• If the dewpoint is between the Full ON and Full

OFF Dewpoint, the heaters

will be pulsed ON for a

percentage of the specified time interval. The per-

centage is determined by proportionately measuring

where the

dewpoint falls between the range of val-

ues formed by the two setpoints.

Figure 11-6 shows an example of an anti-sweat appli-

cation. The setpoints (Full ON = 80°F, Full OFF = 20°F)

fo

rm the range of dewpoints across which the heaters will

be pulsed. When the measured dewpoint is 45°F (directly

in between both setpoints), the percentage will be 50%,

and the heaters will be pulsed ON for five seconds of the

defined 10-second interval. If the dewpoint drops to 30°F,

the percentage will lower to 20%, and the heaters will be

on only two seconds out of every 10.

11.17 Heat/Cool Control

Heat/Cool Control is a special kind of sensor control

that applies to heating and cooling devices. Heat/Cool

Control applications use PID control to vary the amount of

heating and cooling based on the current temperature and

its relation to the heating or cooling setpoint. Both staged

and modulated (0-100%) heating and cooling outputs are

supported by Heat/Cool Control.

Heat/Cool controls are availab

le in RX units, allowing

small installations with simple HVAC systems to use one

controller for all refrigeration and HVAC systems.

11.17.1 Temperature Control

Heat/Cool applications use PID control to vary the out-

put of heating and cooling devices.

As is the case with all

applications that use PID control, Heat/Cool control

makes use of a PID setpoint and a throttling range. Refer

to Appendix D: PID Control for more information.

Unlike normal PID loops that assume a 50% output is

required to keep the temperature stabilize

d on the setpoint,

Heat/Cools strive to stabilize the temperature on the set-

point with the output at 0%. Thus, when the temperature

go

es below a heating setpoint or above a cooling setpoint,

the heating or cooling outputs climb from 0% to 100% as

determined by the throttling range (see Figure 11-25).

Figure 11-25

- Example of Heat/Cool PID Control

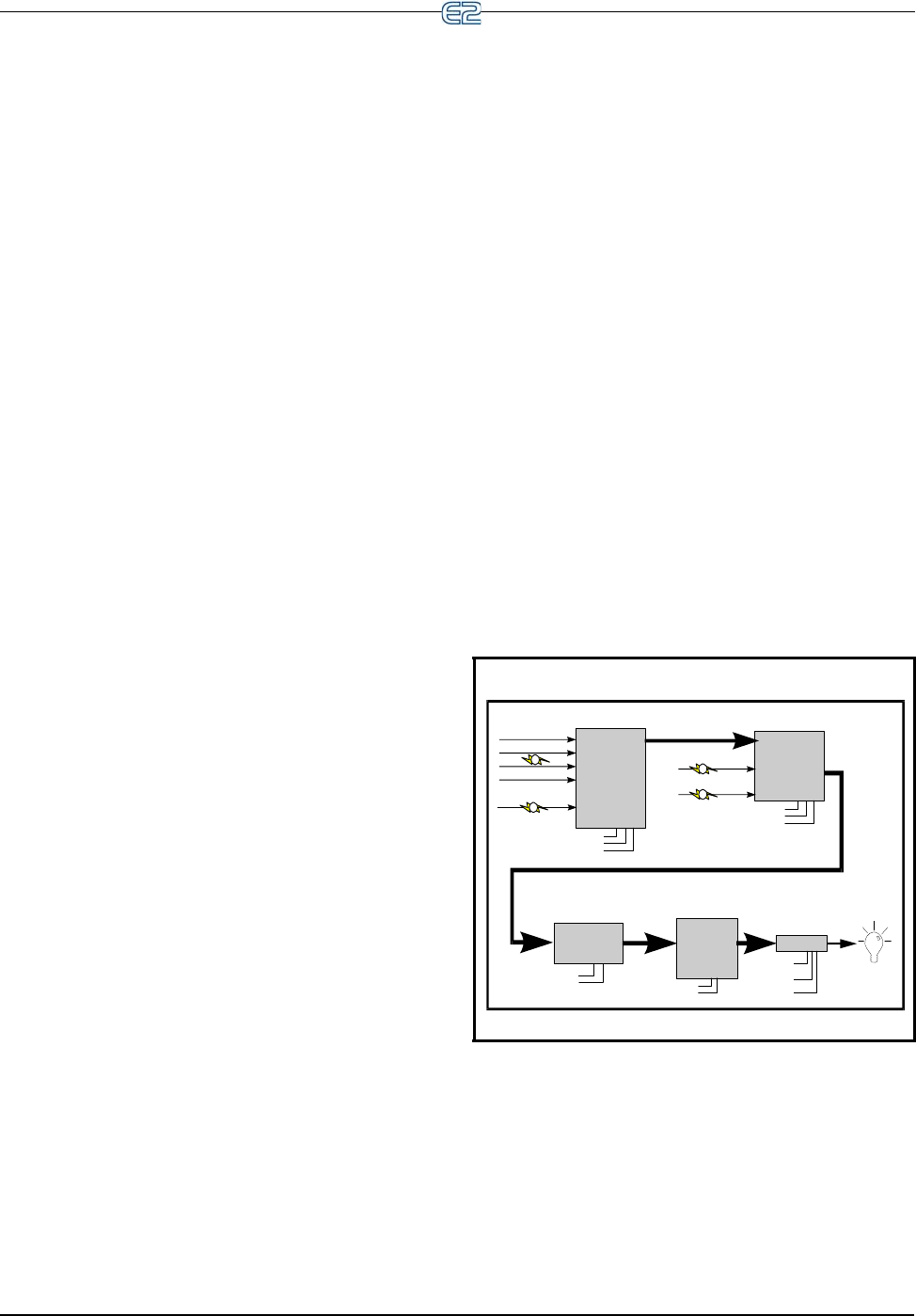

Lighting Control Command Cells

Input Value

1 - 4

In 1

In 2

In 3

In 4

Use Alt Comb

Out

DVCOMBINER

SCHEDIF

Out

Comb Type

Alt Comb

Invert Output

Alt Combiner

DV

Logic In

Sched In

Use Alt Sch

Occupied

DV

Comb Type

Alt Comb

Invert Output

MIN ON/OFF

In Out

ONESHOT

Trigger

Out

In

Out

OVERRIDE

Command

(on, off, normal)

Type

(timed, fixed)

OV time

Pulse Width

Timer

Alt Schedule

DV

DV

Min On/Off Times

Min On/Off Delays

LIGHTS

26512043

By default, only the proportional and integral modes of

PID control are enabled for Heat/Cools. The user may

choose to add the Derivative mode or to get rid of the Inte-

gral mode and use strictly Proportional control.