Service Procedures 185

Appendix D

Duty Cycle Adjustment

The function generator stores two calibration constants related to squarewave

offset and two calibration constants related to squarewave duty cycle. The

constants are calculated from the adjustment value entered. The calibration

constants are stored following completion of SETUP 63. No calibration

constants are stored if the procedures are aborted at any other setup.

1. Use a DMM to measure the function generator DCV output voltage

for SETUP 60 in the following table. These adjustments use a HIGH

Z output termination.

Note For this test, the DMM must be set to a fixed range capable of measuring

from +10 V to -10 V. Do not use an auto-ranging function for this test.

2. Send the CAL:VALue <measured Vdc> to the function generator.

3. Send the CAL? command to the function generator to initiate the

calibration.

4. Repeat steps 1, 2 and 3 for SETUP 61 through 63.

5. Perform the “Square Wave Duty Cycle Verification” on page 172.

AC Amplitude Flatness Adjustment

The function generator stores eleven calibration constants related to AC

Amplitude Flatness from 1 kHz to 15 MHz. The constants are calculated

from the adjustment value entered and one of two calculation constants

related to the type of measurement device you are using. The calibration

constants are stored following completion of SETUP 82. No calibration

constants are stored if the procedures are aborted at any other setup.

This procedure can be performed with one of three types of measurement

device; a broadband ACrms voltmeter, a power meter, or a thermal voltage

converter. The procedure differs slightly depending upon the type of

measurement device used. These adjustments use a 50 Ω output termination.

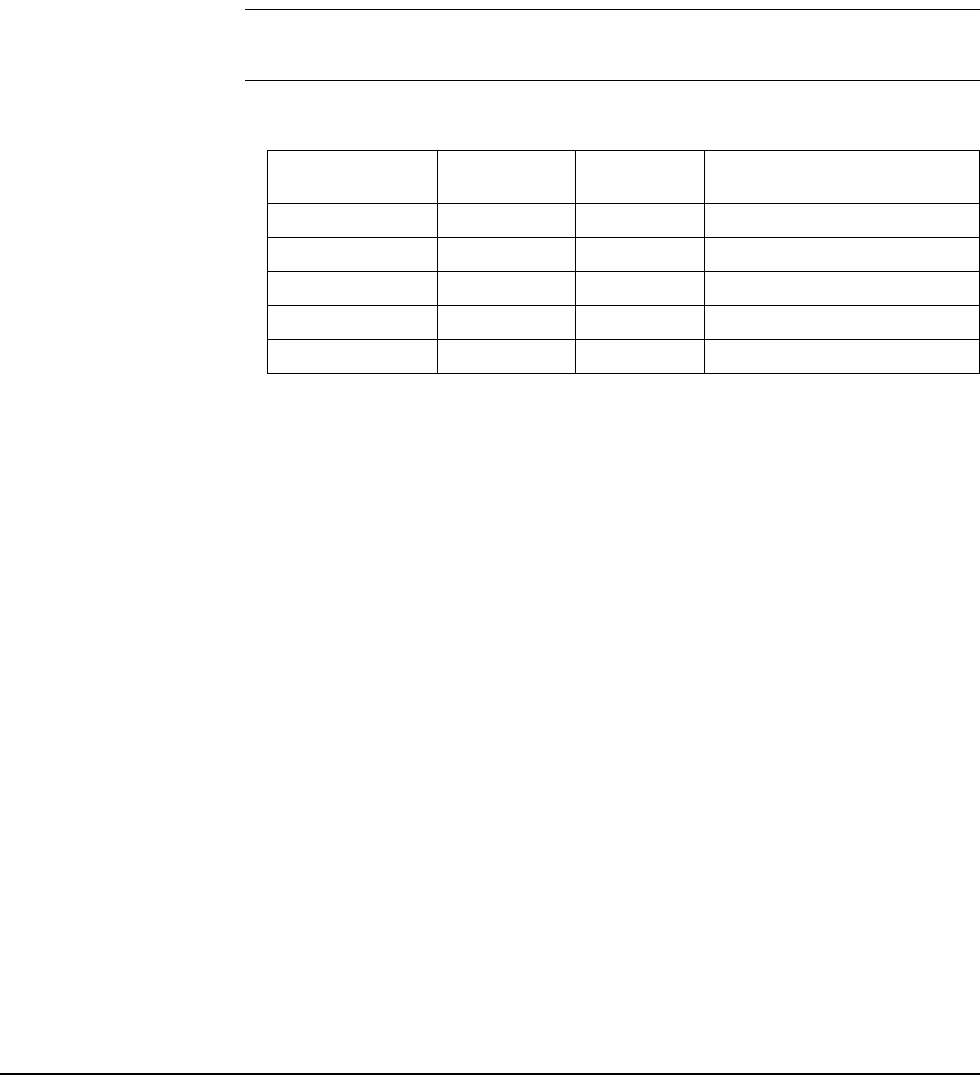

Table D-18. Duty Cycle Adjustment Setups

Nominal

Output

+

SETUP FREQUENCY AMPLITUDE

60 — 10.0 VDC Positive squarewave offset.

61 — -10.0 VDC Negative squarewave offset.

62 300 Hz 0.0 VDC 50% duty cycle squarewave.

63 300 Hz 5.0 VDC 75% duty cycle squarewave