11-10 • E2 RX/BX/CX I&O Manual 026-1610 Rev 13 14-SEP-2011

11.4 Case Control Circuits

11.4.1 Overview

Case circuits that use CC-100s, CS-100s, EC-2s, or

CCBs for case control rely on Case Circuit Control appli-

cations in the E2 to provide them the necessary setpoints,

defrost scheduling, and other control parameters. Unlike

Standard Circuit applications, Case Control Circuits do

not directly control temperature in the case circuits;

instead, the case controller controls temperature for each

individual case based on the setpoint(s) supplied to them

by their associated E2s.

Setup of a case-controlled refrigerated case system is a

two-fold process:

1. For each case circuit in the refrigeration system, a

separate Case Control Circuit application is cre-

ated with its own set of control parameters.

2. Each CC-100, CS-100, EC-2, and CCB is associ-

ated with a Case Control Circuit application in

the E2. Association creates a network link

between the case controller and the application

which supplies the information necessary to con-

trol temperature, defrost, lights, fans, and anti-

sweat heaters.

This section of the manual covers both the program-

ming of a Case Circuit Control application and the process

of associating a CC-100, CS-100, EC-2, or CCB with a

Case Circuit Control application.

11.4.2 Case Circuit Control Soft-

ware Overview

There are six different versions of case control soft-

ware in the Retail Solutions case control family:

• CC-100P - This version controls temperature in a

case using a pulse modulated valve, which is pulsed

ON for a percentage of a fixed amount of time to

achieve the necessary refrigerant flow.

• CC-100LS - This version controls temperature in a

case using a liquid-side stepper valve. This valve is

capable of various positions in between 0% and

100%. As a result, the CC-100 is capable of supply-

ing the exact refrigerant flow necessary to achieve

the case setpoint.

• CC-100H - This version controls temperature in a

case using a suction-side evaporator pressure regu-

lator (EEPR). This valve is capable of various posi-

tions in between 0% and 100%. As a result, the CC-

100 is capable of providing the exact suction pres-

sure necessary to achieve the case setpoint.

• CS-100 - This controller uses suction-side evapora-

tor suction regulators (ESRs) to control suction

pressure for an entire circuit. Unlike the CC-100,

which controls only one case, the CS-100 controls

all cases on an entire circuit.

•EC-2s - The EC-2 is a liquid-side pulse valve case

controller that doubles as a case temperature and

information display. Unlike the CC-100, it is

designed to be mounted on the front of the case, and

has a push-button front panel interface for program-

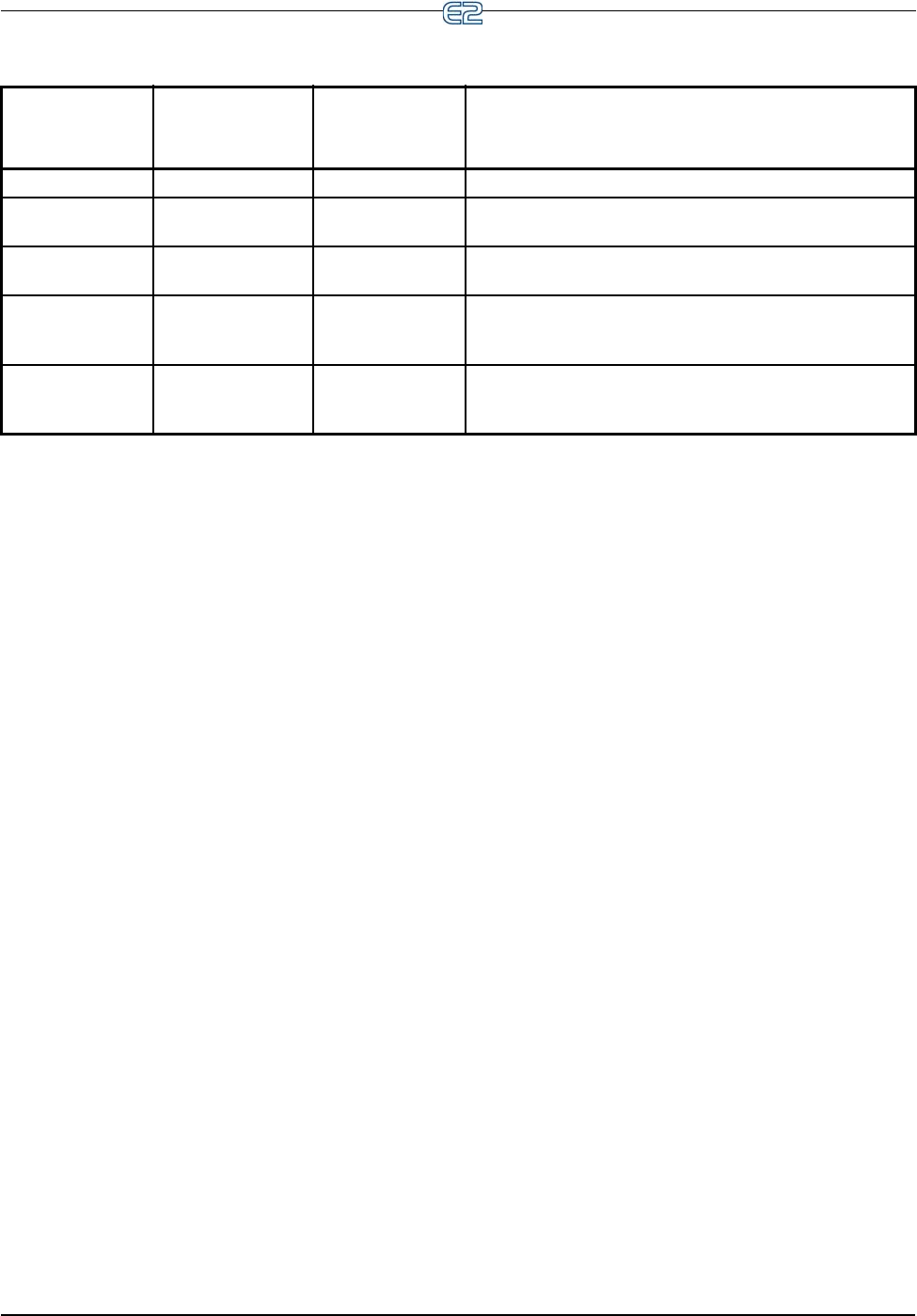

Output Device

Wire Output

Board contacts

to:

Set Fail-safe Dip

Switch to:

Notes

Case Fans N.C. N.C. (up) Wire fans to remain ON during comm. loss

Refrigeration Sole-

noid

N.C. N.C. (up) Wire solenoid to remain energized (OPEN) during comm. loss

Defrost N.O. N.O. (down) Defrost heaters (electric and hot gas) will remain de-energized

(CLOSED) during comm. loss

Liquid Line Sole-

noid (Hot Gas

defrosts only)

N.O. N.O. (down) The liquid line solenoid will remain de-energized (CLOSED)

during comm. loss.

EEPR (ESR8 con-

trolled circuits

only)

None (ESR8 point) None (ESR8 point) The evaporator stepper regulator valve should be plugged in to a

point on the ESR8 board.

Table 11-6 - Suction Group Outputs