11-54 • E2 RX/BX/CX I&O Manual 026-1610 Rev 13 14-SEP-2011

11.23.2 Learning Mode

When an MCC application runs for the first time, it

undergoes a "Learning Mode" period to collect data on the

chiller stages. During Learning Mode, the MCC will con-

trol the chilled water temperature, but it will purposely

cycle the chiller stages in different combinations to mea-

sure the effect they have on the temperature input value.

The Learning Mode lasts for several minutes. After

Learning Mode ends, the MCC will require up to 24 hours

of operation before compressor cycling is operating at

maximum efficiency. If compressor cycling seems too fre-

quent after 24 hours of operation, you may reduce com-

pressor cycling by changing the Control/Cycles parameter.

11.23.3 The Control/Cycles Parame-

ter

The MCC has one parameter with five preset settings

to allow users to alter temperature control performance or

compressor cycling frequency. The default setting, "Mod-

erate Control," seeks to balance good temperature control

with efficient cycling. If tighter control is needed, setting

the field to "Tight Control" or "Tightest Control" will

increase the application's reaction to temperature changes,

resulting in tighter control (usually at the expense of more

frequent cycling). If fewer compressor cycles are desired,

setting the field to "Less Cycling" or "Least Cycling" will

decrease the number of cycles but also increase the

amount of fluctuation in the temperature control.

11.23.4 Compressor Control

MCC can utilize up to 32 compressors for maintaining

the chilled supply temperature at a user specified setpoint.

This is accomplished by either turning on or off any of the

compressors defined in the application. As Supply Tem-

perature rises above setpoint, compressors will be turned

ON. As Supply Temperature falls below setpoint, com-

pressors will be turned OFF. The Chilled Supply Tempera-

ture sensor should be located very close to the Compressor

Control Unit so no minimal control lag is expected to be

present.

When a compressor has been shut down on an alarm,

the compressor will remain out of the active rotation until

the alarm has been cleared. Additionally, the user will

have the option of specifying that the alarmed compressor

be re-tried the next time it comes up in the rotation. To

prevent damage to a compressor, the user will have the

option of specifying a number of trips per day before the

compressor is permanently locked out. Once this condition

has occurred, the compressor alarm will require a manual

reset to bring it back into the active rotation.

The controller will monitor the Chilled Differential

Pressure and if it falls below a user specified threshold, the

controller will start to shut down compressors one at a

time based on a user specified time delay. This shutdown

operation will be suspended if the Chilled Differential

Pressure rises above a user defined setpoint.

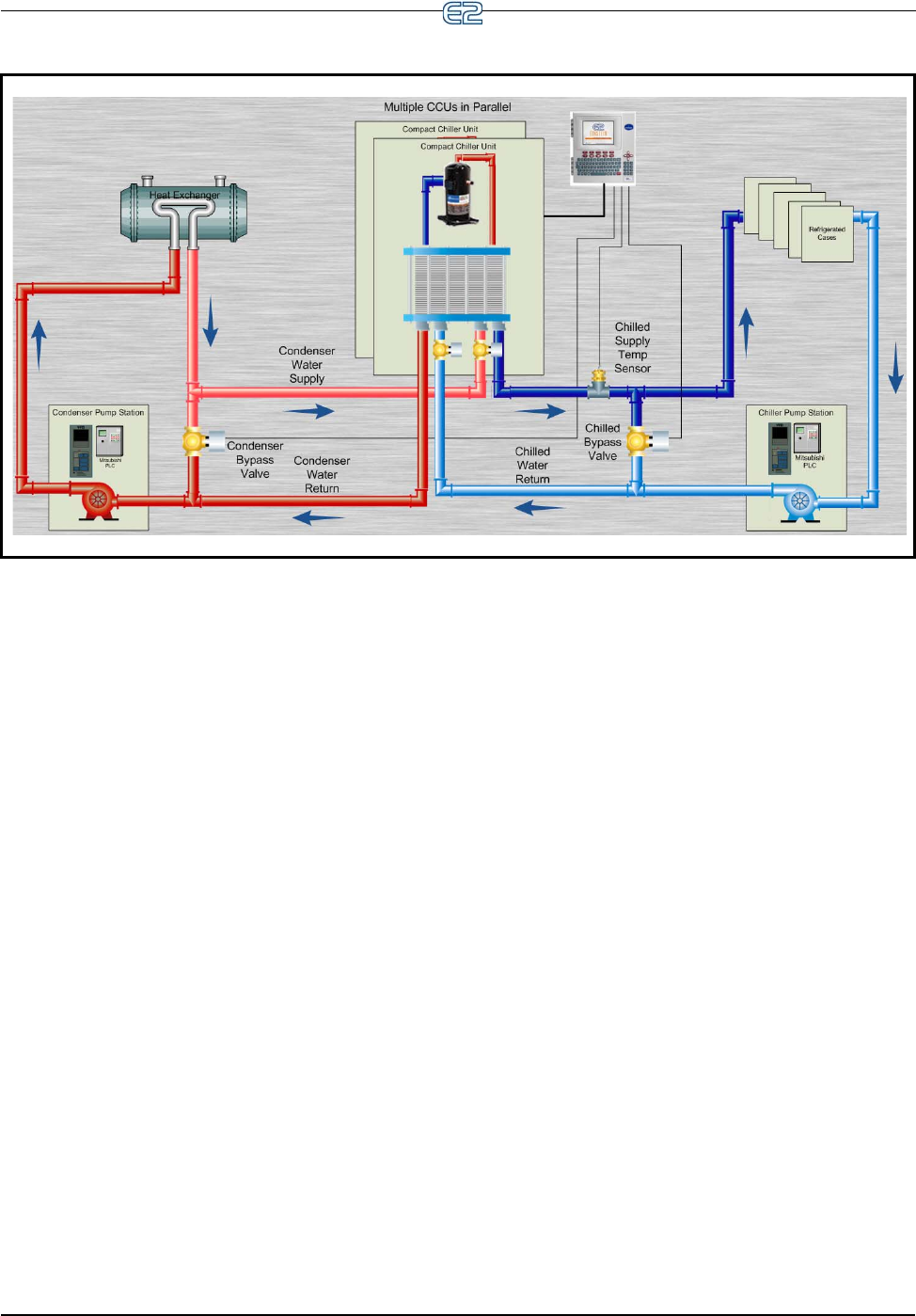

Figure 11-1

- Compact Chiller System