Boiler Software Overview • 11-55

11.23.4.1 Digital Scroll Compressor

MCC can also utilize a single Digital Scroll Compres-

sor. The assumption is that one of the Compressor Control

Modules in the system may have a digital scroll instead of

a standard scroll compressor installed. The Digital Scroll

Compressor may not be the same size as the fixed scroll

compressors. When a Digital Scroll Compressor is defined

in the application, MCC will utilize the compressor con-

trol modules with the digital scroll at all times, modulating

the capacity of the compressor to maintain the Chilled

Supply Temperature setpoint. All other compressor con-

trol modules will be turned ON or OFF based on the rota-

tion sequence defined above. Based on this strategy, the

digital scroll compressor will have the fewest cycle counts

and the most runtime of all the compressors in the system.

11.23.4.2 Variable Frequency Drive Com-

pressor

MCC can utilize one compressor with a variable fre-

quency drive. The method of control will be similar to the

digital compressor strategy. The application will continue

to allow only one variable capacity device to be defined in

the system, making the Variable Frequency Drive and Dig-

ital compressor options mutually exclusive.

If a Variable Frequency Drive compressor is to be used

and it is a Control Techniques drive using the Modbus

communication interface, the Control Techniques Drive

association menu will support associating the drive to an

MCC.

11.23.4.3 Unequal Capacity Compressors

Optionally, the MCC can support different capacity

compressors. When this option is selected, the capacity of

each defined compressor will be user specified. The con-

troller will evaluate the capacities of all the compressors to

determine the appropriate compressor to switch on or off

in order to maintain the Supply Temperature at setpoint.

When unequal capacity compressors are defined, the

controller will not use a simple round robin approach to

switching compressors on or off (as with equal capacity

compressors) and therefore compressor runtimes may vary

significantly over time. However, for those compressors

defined with identical capacity, the algorithm will attempt

to keep both runtimes and cycle counts as even as possi-

ble.

11.23.5 Bypass Valve Control

MCC can utilize the Chilled and Condenser Bypass

Valves. These valves will be modulated to maintain user

defined differential setpoints. For each valve, as the differ-

ential pressure rises above the setpoint, the valve will

modulate open. When the differential pressure falls below

setpoint, the valve will modulate closed.

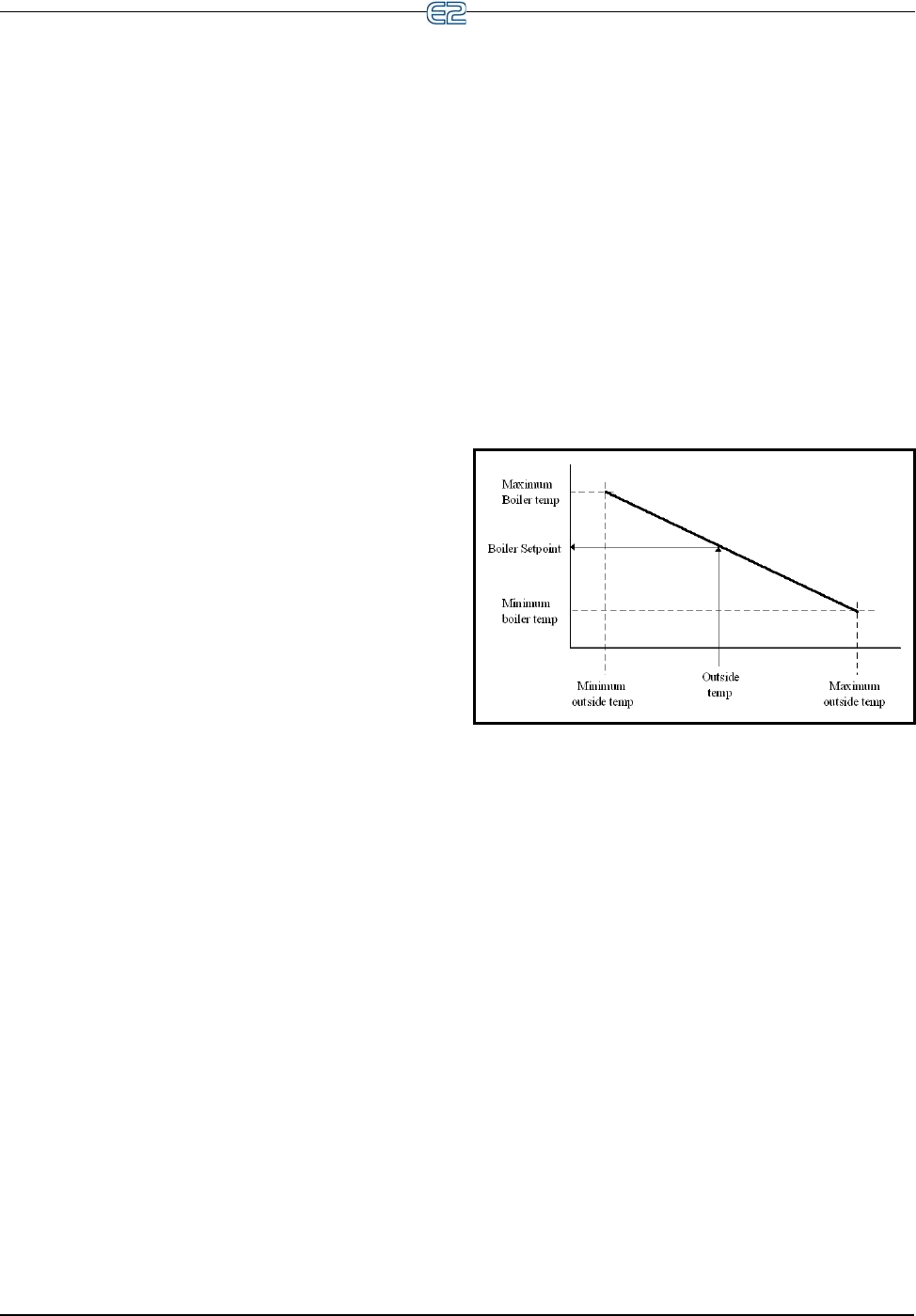

11.24 Boiler

The BX-300 and BX-400 will default to a maximum of

two Boiler applications. Other models will have to license

the Boiler Application. The Boiler will be available only

for E2 versions 3.0 and higher.

11.24.1 Overview

The Boiler can be controlled two ways, via the boiler

temperature or the boiler pressure. The E2 uses the current

outside air temperature to calculate a new boiler control

setpoint. If the boiler temperature (or boiler pressure) is

less than the setpoint value then the boiler is turned ON.

Otherwise it is turned OFF. The algorithm will work in an

inverted fashion if the Minimum Outside Air Temperature

is greater than the Maximum Outside Air Temperature.

An Outside Air Temperature Boiler On and an Outside

Air Temperature Boiler Off can be defined. If the outside

air temperature is lower than the Outside Air Temperature

Boiler On the boiler is turned ON. If the outside air tem-

perature is higher than the Outside Air Temperature Boiler

Off the boiler is turned OFF.

If defined, the Outside Air Temperature Boiler Off

must be greater than the Outside Air Temperature Boiler

On.

11.24.2 Alarms

There are four advisory generated by the Boiler Appli-

cation:

• High Temperature

• Low Temperature

• High Pressure

• Low Pressure

Each advisory will have an associated type, priority,

and delay.

Figure 11-1

- Temperature Ranges