Demand Control Software Overview • 11-35

As mentioned in Section 11.11.1, Introduction to

Demand Limit Control, all KW input values are gathered

together and averaged together in a demand window. The

demand setpoint is then subtracted from this average. The

result of this calculation is called the integral error (or

integral) of the demand window. The integral error repre-

sents how far below or above the setpoint the input has

been for the entire demand window.

Under non-demand conditions, the integral error will

be below zero, since the average KW or watt-hour value

will be below the setpoint.

The current value of the integral error and the current

value of the KW input are what determine when the

Demand Control application will begin load shedding.

11.11.3 Load Shedding

11.11.3.1 Definition

Load shedding is the process of curbing the amount of

kilowatt usage within one or more target applications.

Most applications that drive mechanical or electronic

devices, such as lights, heaters, air conditioners, compres-

sors, etc., are configured with special inputs that, when

active, “shed” the application.

Physically, when a device is “shed,” its control set-

points are altered by a specified amount in a direction that

will save energy. For instance, an HVAC unit with heating

and cooling stages that is commanded to shed will have its

heating setpoints lowered and its cooling setpoints raised.

This will cause the HVAC unit to operate at a lower capac-

ity, thus saving energy.

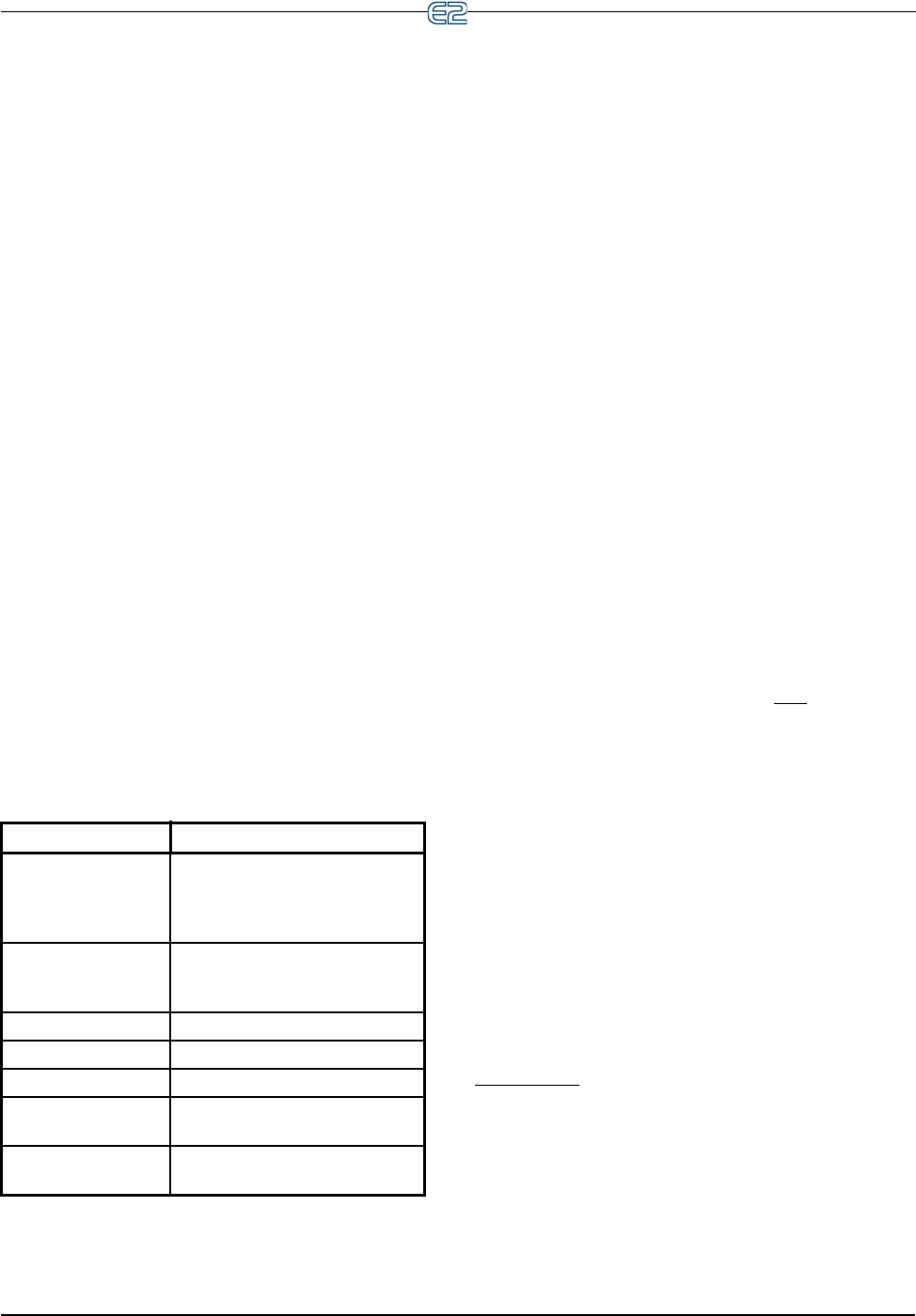

Table 11-13 lists a number of E2 RX-300 and BX-300

applications and how load shedding affects them.

11.11.4 Shedding Levels

Some applications have a single input (usually called

DEMAND SHED) that, when ON, sheds the application.

Each application is programmed with a specific “demand

bump” value that is added or subtracted from the control

setpoints when this input comes ON.

Other applications, notably HVAC applications, have

two inputs: a primary and a secondary (usually called PRI

DEMAND SHED and SEC DEMAND SHED). Each

input has its own “demand bump” value, so that when the

primary is ON, the primary demand bump is in effect, and

when the secondary is ON, the secondary demand bump is

in effect. When both of these inputs are ON, the demand

bump values are added/subtracted together and applied to

the setpoint(s). As a result, two levels of shedding are pos-

sible for a single application.

Example: An air conditioner with a cooling setpoint of

70°F has a primary demand bump value of 2 and a sec-

ondary demand bump value of 2. In a typical Demand

Control application setup, the PRI DEMAND SHED input

would be one of the first inputs to go into shed; when this

occurs, the bump value is added to the cooling setpoint,

raising it to 72°F.

The SEC DEMAND SHED would be set up to shed

later (if necessary) as a second level of shedding for the

air conditioner. When this input is turned ON, the setpoint

is raised by the secondary demand bump value. Since the

PRI DEMAND SHED input is still ON, both

values are

added to the setpoint, raising the setpoint to 74°F.

11.11.5 Priority Levels

Each application that you wish to set up for shedding

must be assigned a priority level in the Demand Control

application. When a Demand Control application sheds

loads, it does so by shedding all applications that are in the

first priority level, and then continuing to shed higher pri-

ority levels until the demand is at an acceptable level or

until all levels are shed.

Priority levels are simply outputs that connect to the

demand shedding inputs of one or more applications.

When a level is shed, the output comes ON and all appli-

cations connected to the output are shed.

There are three types of priority levels:

1. First Shed

First Shed levels are the first ones to be shed when

demand shedding begins. The Demand Control applica-

tion first begins shedding by activating level #1 of the

First Shed levels. As needed, each level thereafter is shed

in succession (#2, #3, and so on to #20).

Applications that are part of the First Shed priority lev-

els should be non-vital applications that would have no

Application Shedding Effect

All HVAC applica-

tions (RT-100s, Multi-

Flex RTUs, AHUs,

Heat/Cools)

Raises cooling setpoints, lowers

heating setpoints

Sensor Control and

Analog Input I/O

Modules

Raises or lowers Cut In/Cut Out

setpoints (whichever direction

saves energy)

Refrigeration Circuits Raises case temperature setpoints

Suction Groups Raises suction setpoint

Condenser Raises discharge setpoint

Analog Output I/O

Modules

Raises or lowers PID setpoint

(whichever will save energy)

Digital Output I/O

Modules

Control output is locked OFF.

Table 11-13 - Shedding Effect on Applications